How to Select the Right Materials for CNC Prototyping

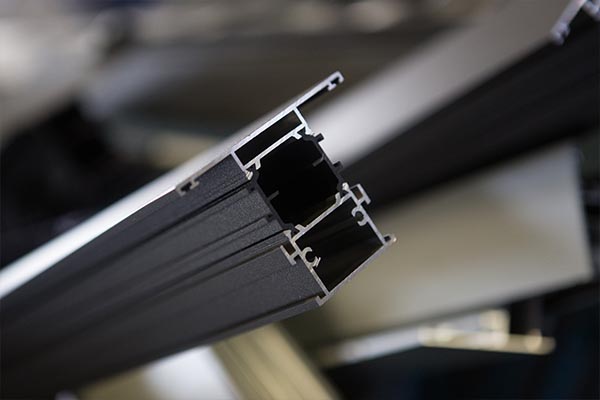

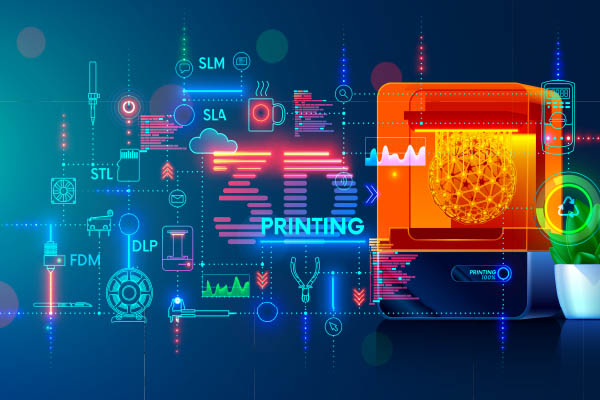

CNC prototyping presents new opportunities for product development and rapid prototyping. Because of the versatility of CNC technology, product developers can quickly evaluate concepts, feasibility, and iterate design. The advantages of CNC prototyping also cut across cost savings, elimination of tooling costs, and the ease of correcting models through CAM/CAD software.

Today, we look at a crucial step in CNC prototyping – material selection. Material selection is essential for CNC prototyping for many reasons; First, you want to test and prototype with the exact material or the closest substitute to be used in the final product. You also want to evaluate the ease of machining and the raw material’s functionality and cost for both prototyping and mass production. Read on to discover our best practices for choosing the suitable material for your CNC prototyping.

CNC prototyping VS Traditional prototyping

It is essential to understand why choosing the right material for CNC prototyping is crucial to product success. To emphasize this, we put CNC prototyping against conventional means of prototyping. Here are the results:

• First, CNC prototyping is a form of rapid prototyping, and it is designed for quick turnaround. Because of this, it is essential to refrain from using expensive materials that you may discard until the perfect prototype is achieved. There’s no point in having high material waste costs when you can try other alternatives that are more affordable for rapid prototyping.

• Second, traditional prototyping methods may favor the use of tooling. Tooling costs are quite high (due to tooling materials) and will drive up the overall production/prototyping costs.

• Third, CNC prototyping uses CAD/CAM models for work. These digital drawings allow for on-the-go modifications depending on the outcomes of the tests and the desired end products. Choosing the right material for CNC prototyping will enable you to evaluate all properties (physical, cosmetic, mechanical, functional) of your product with high fidelity models.

Selecting the right material

Before commencing your CNC prototyping process, consider these factors:

Product appearance: What will the selected material look like when the final prototype is produced?

1. Physical strength

How does the material deliver on the desired physical attributes, rigidity, durability?

2. Chemical, physical and physicochemical properties

How will the material react in real-life scenarios? Is the product to be used under extreme pressure or temperature conditions? What is the level of elasticity, strain, and stress it can handle? Is it fire retardant? Chemical (corrosion/rust) resistant?

3. Ease of machining

Will the selected material be easily machined into the final part, or are they complications? Remember that complex material that requires more effort to machine demands higher cost and labor input.

4. Cost

Does the desired material land the product at the right cost? Is there still room for profit? Are there suitable alternatives at more affordable price ranges? Is there going to be a need for post-machining costs?

5. Product functionality

Does the material deliver on the product functionality, ease of use, feel, and safety of your intended product?

After you have put these factors into consideration, you can now embark on these steps to select the material:

What properties are critical to your product

Depending on what product you are manufacturing, the critical properties of your part will vary from other products. For instance, elasticity may be a desired attribute along with strength. In cases like these, metal materials are likely to be unsuitable, and high-density plastic resins may be more appropriate. Factor in your target market and conclude on the primary attributes that your product needs to have (including cosmetics). Once you do this, you will find that many materials fit your need. Move on to the next phase below.

Shortlist, test, and record

After determining the critical product properties, proceed to shortlist the materials that meet your specifications while factoring in cost and availability. Depending on the number of resources available, you can use each material’s datasheet to further analyze or perform CNC prototyping with each material, obtaining various prototypes ready to be evaluated and tested.

Analyze, select and validate

After testing the desired materials, select the one that best fits the end purpose. Again, all the factors above you should consider. Once you are convinced of a material, validate your product design by building prototypes and putting them through several functionality tests, consumer and market testing till you get it right.

Get started Premium Part CNC prototyping in China

Approaching material selection from a strategic planning perspective is important if you’re getting it right with your product development. Before concluding on the materials, you have in mind, speak to an expert, consider the material datasheet, and query if the material ticks all or most of your boxes, including cost, functionality, physical and cosmetic properties. We offer excellent CNC machining and rapid prototyping services at Premium Parts in China. Get in touch with us to review your new project and get a free quote.