CNC machining is our core ability to provide fast lead time, and sufficient engineering support.

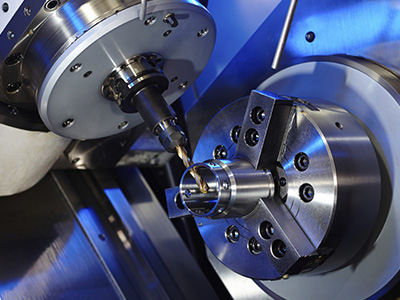

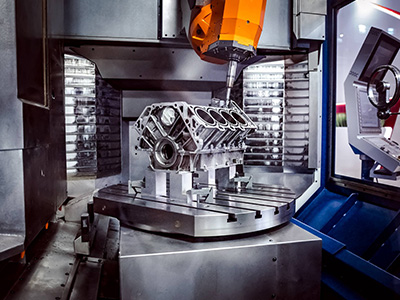

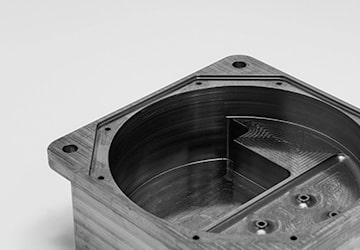

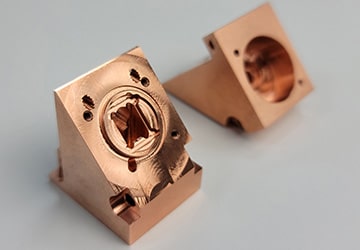

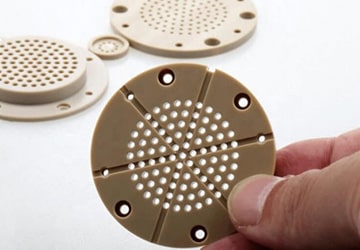

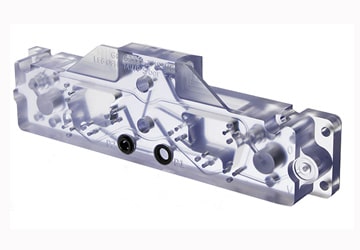

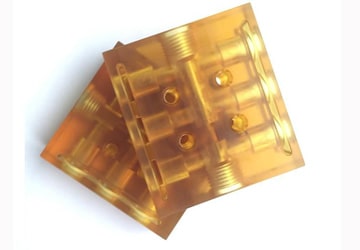

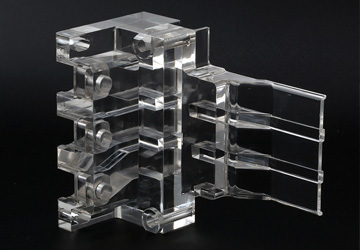

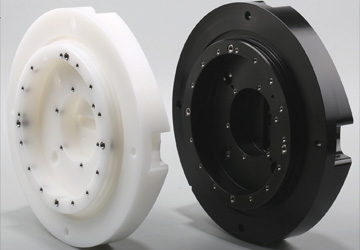

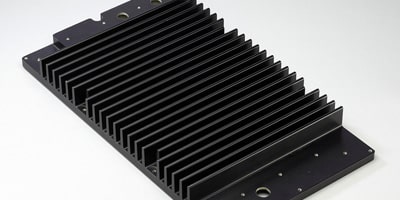

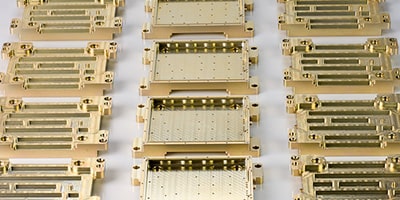

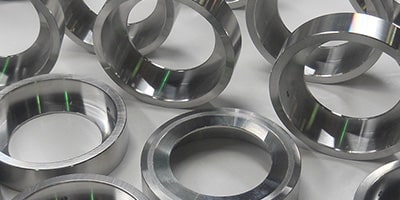

Premium Parts provides high-precision CNC milling, CNC turning, and EDM machining operations to make complex tooling, functional prototypes, and final products for various industry applications. We work with different engineering-grade metals and plastics to make high-quality custom CNC machining parts or CNC components delivered to specifications. With an excellent range of finishing services, pronounced product quality, on-time delivery, and service diversity, we can take care of all your CNC machining needs! Our in-house capabilities and quality control can deliver the best output fitting your specification and standard with high repeatability and scalability. We are an experienced team, and we will try our best to evaluate your project, production design, and suggest the best approach from process to material and budget.