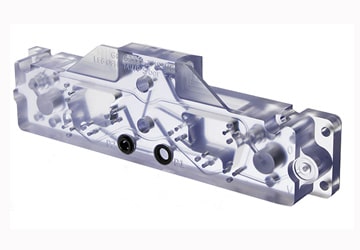

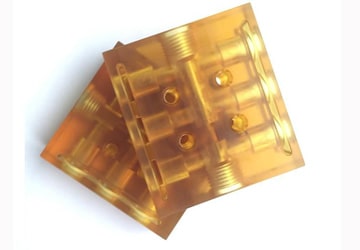

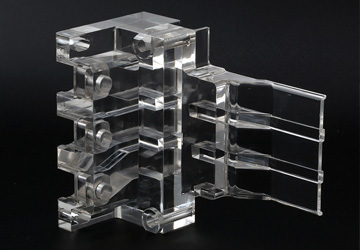

Unlike other parts creation processes like 3D printing, CNC milling machines subtract material from a block or sheet until the desired piece remains. This subtractive method uses multiple cutting tools and surfaces that rotate, revolve, tilt, and slide. Machines are frequently designated as horizontal, vertical, or multi-axis milling.

Horizontal

The cutting tool moves in from one or both sides.

Vertical

A tool presses against the mounted material, much like a drill press.

Multi-axis

Tools come from the top, sides, and on diagonal axes, as needed for more complex parts milling.

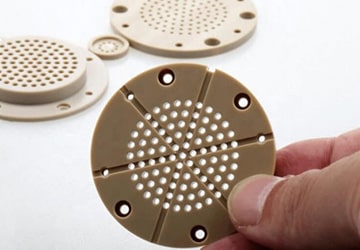

Besides the configuration of the cutting tools and materials, CNC milling operations also differ based on the type of cutting or material removal they do. These methods include surface, face, form, or angular milling.

Surface

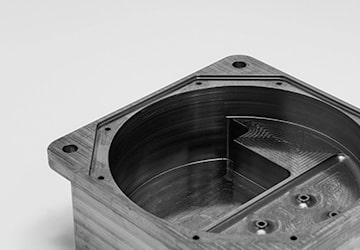

A tool cuts away material from the surface parallel to the part.

Face

A perpendicular tool on one side removes the material.

Form

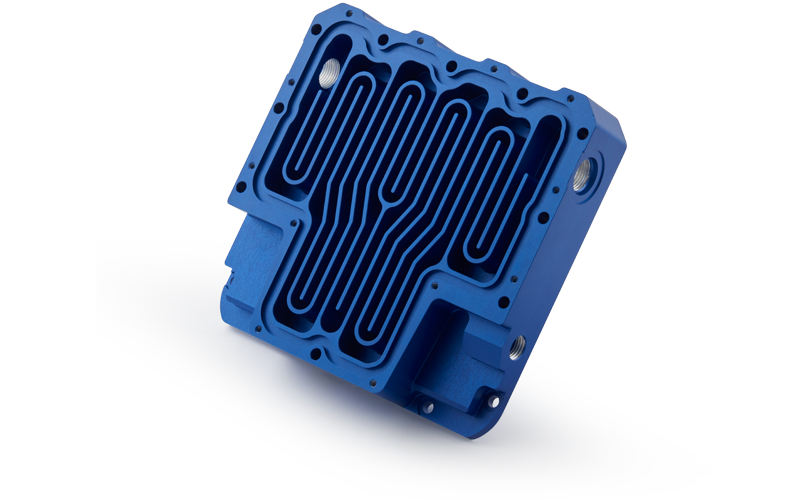

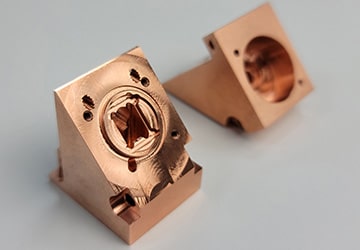

Removing material in curves and contours using bespoke tools.

Angular

Create grooves and joins using angled tools from different sides.

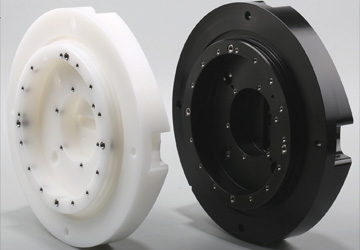

How the material gets held and the cutting or milling method matter extensively when delivering the precise part. However, two other criteria go into a custom CNC milling job. These include how operators mount the materials to the machine and securely hold them. And how to change the tools during workpiece creation.

Of course, it is of the utmost importance that the material never shifts or vibrates excessively during milling. This would create discrepancies in the measurements of the plan and the final piece. CNC machines do not usually hold the material, and thus the finished part, on a spindle. Instead, They are held with various vices and clamps or custom-made fixtures designed and created on one of these machines.

Some milling machines require manual tool changes between different parts of the milling procedure. One cutting tool does its job, the machine is stopped, a person changes to a new machine, and the work continues. Others use automatic tool changers that are set up ahead of time with all the necessary choices needed to complete a particular workpiece project. This is, of course, more convenient and hands-off.

.jpg)