Toys 3D Printing

Toys 3D Printing

Image Description: The image shows colorful toy models made with a 3D printer. The printer is creating small toys layer by layer using plastic filament.

Additive manufacturing is one of the hottest technologies in manufacturing today. And while 3D printing is the driving force behind many revolutionary breakthroughs, it’s not always all business. This blog looks at some of the most interesting facts about 3D printing you probably do not know. Let’s get right into it!

1. 3D printing is an 80s baby

3D printing has been around for a while. But just how long is a time? Well, 3D printing technology has been in existence since the 1980s. Although the most recent buzz about 3D printing only started making waves in the last decade, this game-changing technology was first patented by some Frenchmen in 1984. Forty years later, additive manufacturing remains a force to be reckoned with, whether you’re prototyping, mass-producing, or simply being creative in your own apartment. And oh, like all 80s babies, 3D printing rocks!

2. You may be able to eat 3D-printed food

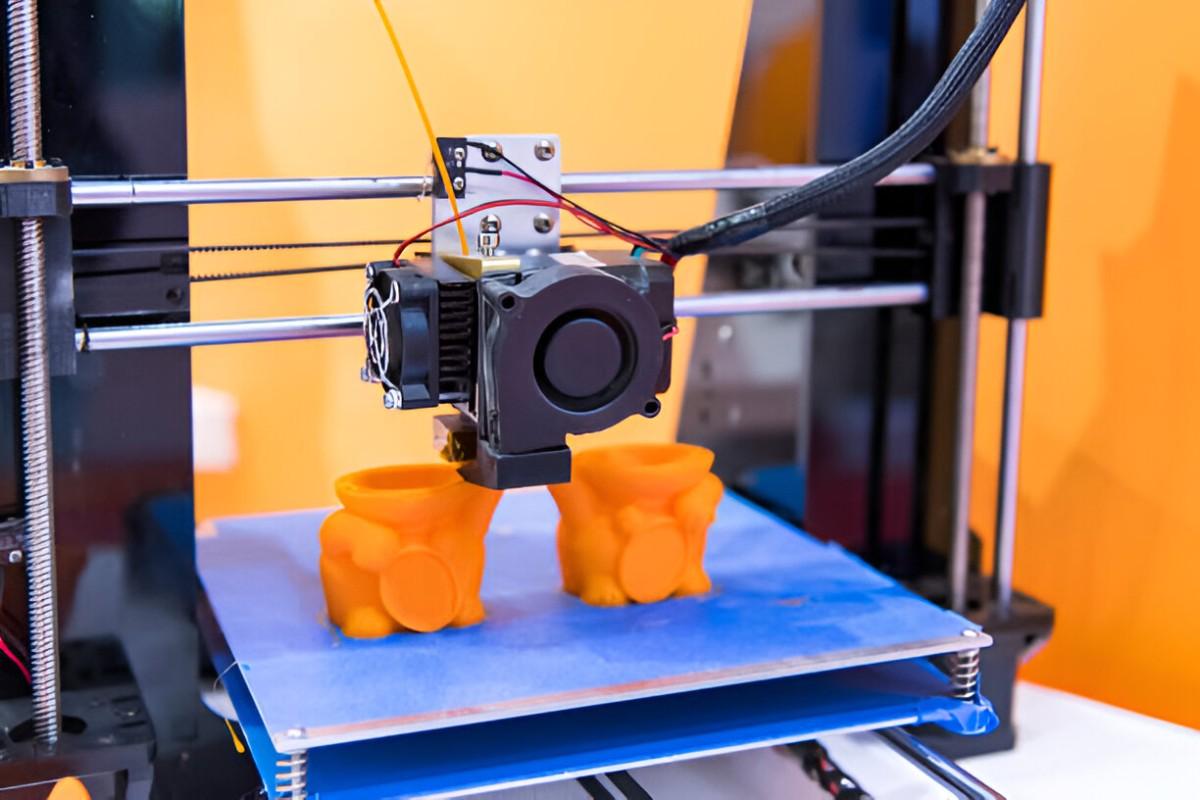

Concept 3D Rendering of Meat

Concept 3D Rendering of Meat

Image Description: The image shows a concept 3D rendering of meat. The digital model displays realistic textures, colors, and details.

Additive manufacturing pushes far and hard when it comes to what can or can’t be 3D printed. Today, scientists and food technologists have already successfully 3D printed vegan steaks, chocolates, and meat. Through specialized techniques, biotechnologists can create synthetic tissues resembling those we have in our food. Manufacturers are gradually beginning to accept the possibilities of chocolate 3D printing and how it can help achieve the complex patterns and designs that will otherwise be complicated by handwork.

When it’s all said and done, the central question here is this? Can we eat 3D-printed foods? Well, NASA has already made 3D-printed pizza for feeding astronauts in space. We guess for the rest of us, time will tell.

3. 3D printing can do much more than prototyping

There are many misconceptions about the capabilities of 3D printing. Some believe it is only suitable for prototyping; others believe it is solely used to manufacture fake or inferior products. Luckily for us, neither of these statements is true. Admittedly, 3D printing is more often used for concept testing and creating rapid prototypes. However, it is very possible and equally widely used to create functional end-use parts. A popular report, “State of 3D printing,” explains that over 50 percent of its survey respondents use 3D printing to produce final parts.

4. You can or already wear 3D

From clothes, bags, and shoes to jewelry, watches, and sunglasses, 3D printing is widely used in the fashion industry to create products for top designer brands. Popular manufacturers such as Adidas, Nike, and Gucci have used 3D printing to produce entire products or components of their final products. For manufacturers in the fashion industry, additive manufacturing presents a valuable opportunity to create many variants of a brand, limited editions, and custom-made designs for bespoke offerings that cater to the diverse tastes of a wide range of customers. It also offers a solution for inventory management as its on-demand availability means lower costs for inventory storage. Dita Von Teese, a beauty model, is one of the few people and the first to have adorned a 3D printed dress made from over 3000 parts through additive manufacturing.

Away from fashion, 3D printing is lending prosthetic arms and legs to many physically challenged patients who have lost limbs to accidents and health-related causes. With 3D printing, affordable prosthetic appendages can be created quickly, providing functional and practical solutions in healthcare. There are ongoing innovations utilizing a technique called Stereolithography apparatus for tissue engineering (SLATE), which enables the 3D printing of small vascular networks to promote breakthroughs in blood and organ science.

5. 3D printing is a movie star

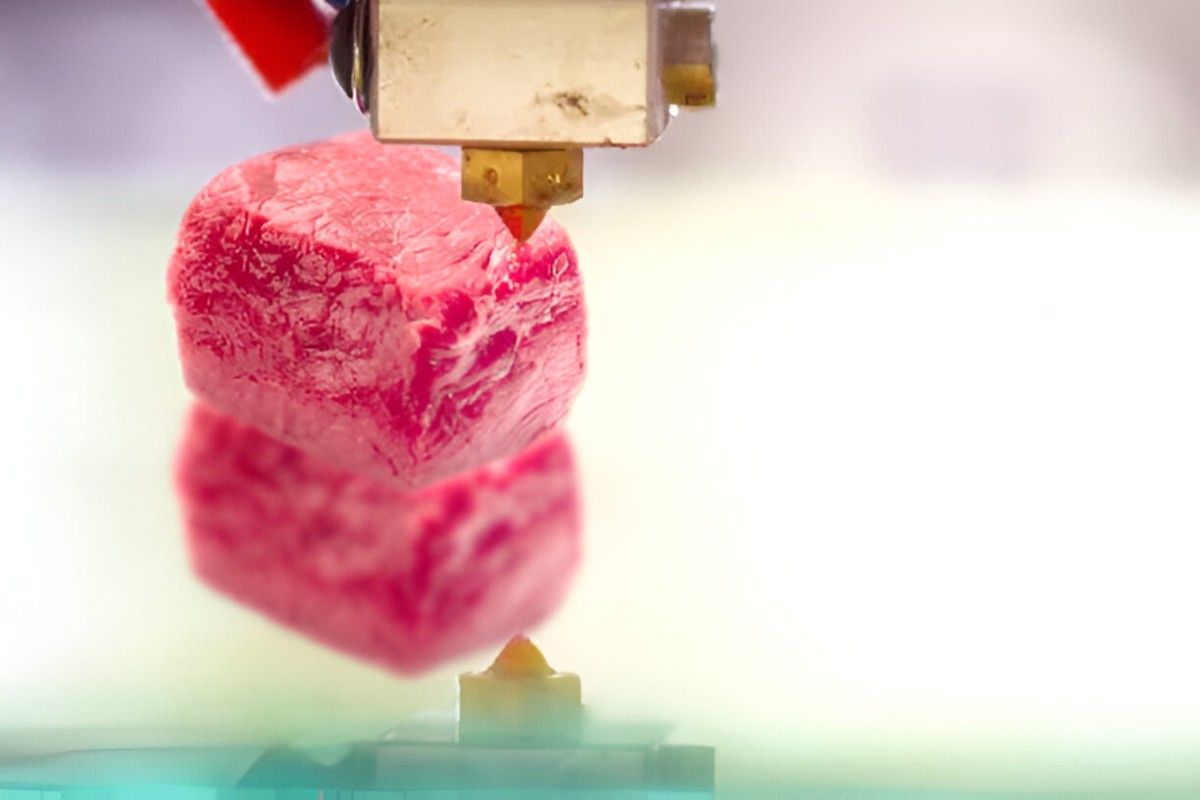

3D Printed Astronaut

3D Printed Astronaut

Image Description: The image shows 3D printed astronaut figures showcased on display.

The use of 3D printing in movie-making is well-documented, as evidenced by the nominations and awards won by record-breaking films like Black Panther and Game of Thrones. In 2018, Marvel Studios employed 3D printing to create the Black Panther vibranium bodysuit, Queen Ramonda’s neckpiece, and crown. Thrones also used a lot of additive manufacturing for creating props such as Wallgons, The Wall in the north, Castle Winterfell, and Warships. Even movies like Iron Man, Jurassic Park, Terminator, Avatar, and The Avengers have all relied on 3D printing in many ways. 007 Movie, Skyfall also featured the use of 3D printing in the making of a full Aston Martin DB5 used by James Bond in multiple scenes in the movie. Depending on your level of expertise, you might be able to print yourself a Spider-Man suit and become your friendly neighborhood superhero.

6. 3D printing can print body organs

Human Blood Vessel Printed on a 3d Printer

Human Blood Vessel Printed on a 3d Printer

Image Description: The image shows a person holding a 3D printed model of a human blood vessel in his hand.

3D printing has found many staple applications in the medical industry, but its importance in organ and transplant breakthroughs cannot be overstated over the last couple of years. With 3D printing, surgeons and doctors can work with engineers to produce body organs that will otherwise require donors who match. From kidneys to heart 3D models, hospitals are advancing in surgeries and managing transplant and implant risks more effectively.

Although no 3D-printed organ has been successfully implanted into any patient, medical experts and scientists are optimistic that a breakthrough is on the horizon.

7. 3D printing can be risky

As is the case with every innovation, 3D printing could potentially be exploited for wrongdoings. With the aid of a simple SLA printer, additive manufacturing can be used to replicate fingerprints, plant evidence, and bypass privacy with minimal effort. As debates continue to drag on, gun laws remain very open, and 3D-printed guns can be potentially chaotic in society. With no more than a CAD model, everyday printers can 3D print guns that fire at high speed. Even worse, bullets for these guns can also be printed conveniently from home.

8. The 3D market is growing at breakneck speed

3D printing is not just interesting; it’s rewarding. This year alone, the additive manufacturing market is expected to hit a whopping $8.4 billion. Research published at Inkwood also estimated a compound annual growth rate of 17% until 2027, placing the expected growth in this time frame at around $44.3 billion. If you’re looking to make a significant income, now is the ideal time to get involved in the 3D printing industry.

Get your 3D Printing Project Started Today

Are you looking for a printer for your latest 3D project? Do you need something more than the everyday 3D printing capabilities? Premium Parts’ 3D printing solutions can offer you excellent services that ensure accuracy, scalability, and repeatability at a cost-effective price.

All our parts are thoroughly scrutinized for quality control, ensuring that only the best parts, as light as possible, functional, and practical in performance, are produced from even the most complex 3D designs. Contact us and get your free quote today!