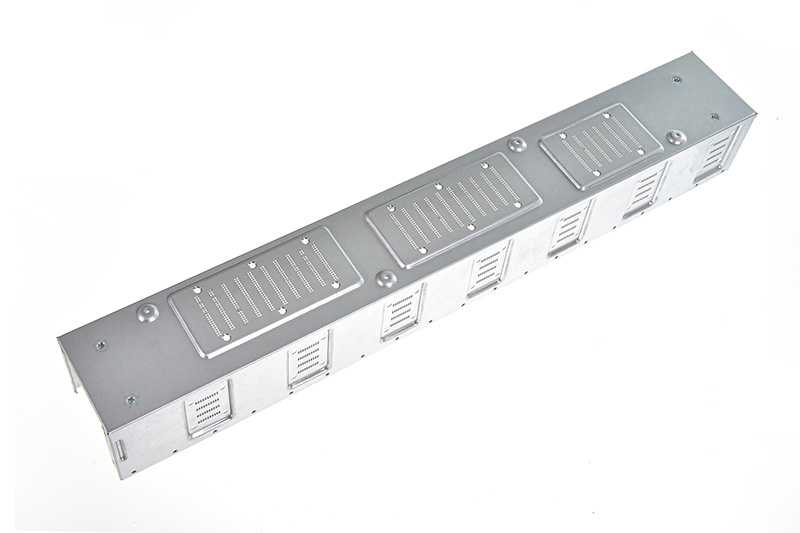

Custom and precision sheet metal prototypes and low-volume parts in 5-7 days

Premium Parts is your one-stop manufacturing shop for making custom precision parts from an array of sheet metal materials. Our sheet metal fabrication solutions are geared for making a non-exhaustive list of parts with simple or complex geometries, excellent finish, and improved functionality.

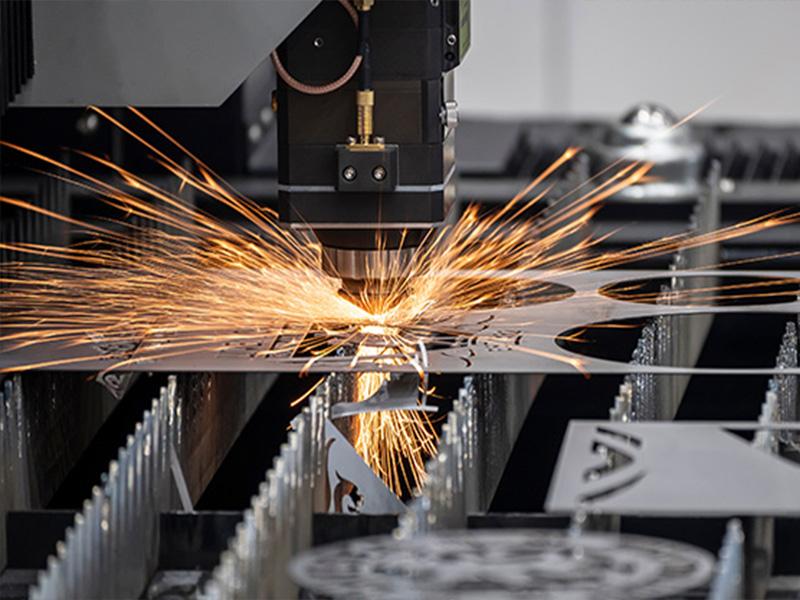

Our services in China are ideal for rapid prototyping and on-demand, low-volume production. By integrating laser cutting and precision forming, Premium Parts delivers a high level of precision and tight tolerances to ensure that your parts match specifications and work as intended. We also offer a range of in-house finishing techniques and treatments to improve your parts post-fabrication.