What is Plastic Injection Molding?

At Premium Parts, we have designed our plastic injection molding processes for quick prototyping and on-demand, mass-volume production. Our parts can serve industrial, commercial, and household purposes.

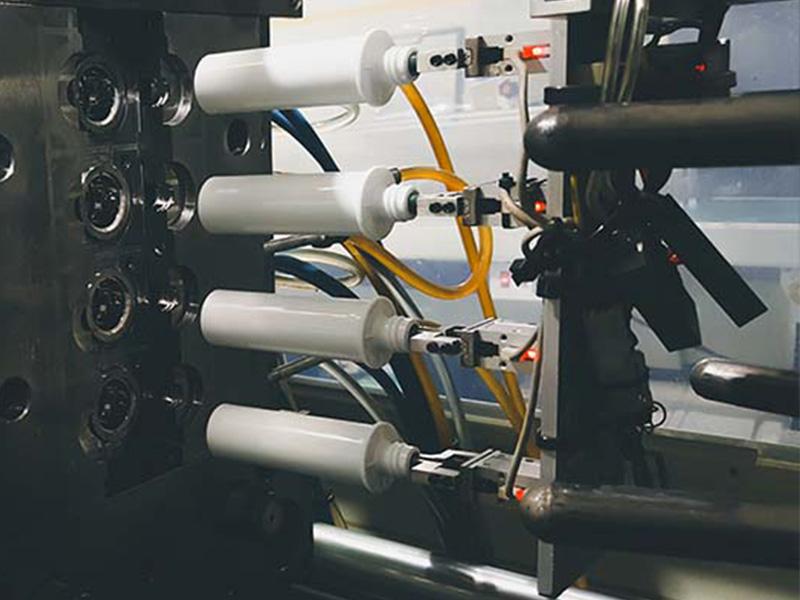

The injection molding technique involves the infusion of molten resin into a metal die cavity under high pressure. The resin is then rapidly cooled to lower the temperature and aid in forming a solid shape that fits the shape of the die. Once the tooling has been made, the actual injection molding process lasts only a few seconds to mold parts depending on the material, part size, and design complexity.

Plastic injection molding is often reserved for making high-end parts with production-grade materials. Premium Parts can, however, apply low-tooling operations to carry our low-volume production for bridge-to-market, pilot testing, market validation, and other mid-scale operations.

Our process flow makes your injection-molded parts in 6 key steps, as shown below:

Our Injection Molding Services

Premium Parts offers a range of services under our injection molding solutions. Some of our injection molding capabilities are summarized below:

• Mold Making

Premium Parts leverages digital design and manufacturing solutions like CNC machining and EDM to facilitate mold making. Our high-quality molds can manufacture thousands of quality end-use parts. We also carry out rapid tooling at affordable rates for low-volume production with aluminum molds.

• Insert molding and Overmolding

Make composite parts with our overmolding and insert molding capabilities. Overmolding is applied to making single parts from multiple thermoplastic and elastomeric materials. It involves the molding of a secondary material over a first to compliment performance and functionality.

Insert molding also creates composite parts by molding plastic fragments over pre-fabricated parts with metal materials. Insert molding is the technique applied in making parts like screwdrivers, fasteners, clips, and scalpels that house sharp features but require some grip for safe handling.

• On-demand manufacturing and Plastic injection molding

Our plastic injection molding can make high-quality plastic parts with excellent cosmetic finish quickly and affordably. Once the tooling has been designed and produced, our plastic injection molding can make low and high-volume parts for various prototyping, testing, and end-use applications.

• Multi-cavity molding

We can perform family/multi-cavity molding solutions for making plastic parts. Our family molds will produce two or more different parts of the same material in one injection molding cycle. Easy and efficient for the production of parts with multiple components.

Why Injection Molding?

• Excellent quality

Injection molding captures even the tiniest detail for your part and delivers on functionality and a cosmetic finish. Injection molding can also make plastic parts with complex geometries and dimensional accuracy.

• Scalability and mass production

Plastic injection molding can make hundreds of thousands of identical parts. It has a high level of repeatability and consistency across manufactured parts.

• Tool life span

Use your high-quality tooling to make and re-run thousands of parts in multiple production cycles. The tool life span depends on the material, geometry, and production process.

• Material diversity and options

Choose from a wide range of thermoplastic materials to make your plastic prototypes and end-use parts. You can also leverage overmolding and insert molding to make parts from a combination of materials.

• Low-volume manufacturing

Use custom aluminum tooling to lower costs and run rapid injection molding for prototyping and low-volume production.

• Finishing options

Compliment your part appearance and functionality with the array of finishing options offered by Premium Parts.

Why Premium Parts Injection Molding?

Take advantage of our professional injection molding services and produce top-tier quality parts that match your specification and production needs. Our injection molded parts are hand-vetted and built to last. Here are some other reasons why we are your one-stop plastic injection molding service provider in China:

1. High-quality parts

Premium Parts boasts of experienced operators and engineers with strict adherence to design, model, and production specifications. All our parts are subject to a stringent in-house quality control service that ensures that we deliver only the best.

2. Experience and Expertise

With thousands of projects amounting to million parts manufactured, our team is budding with experts and experience in both the USA and Europe manufacturing markets.

3. Scalability and Precision

Enjoy concurrent product quality across all production scales from 1 to 10,000+ parts.

Enjoy concurrent product quality across all production scales from 1 to 10,000+ parts.

4. Cost-Effectiveness

We offer a free design-for-manufacturability analysis to ensure design optimization for cost efficiency. When running higher volumes, our cost-efficient injection molding process delivers less waste and lower price per part. This gives our clients the ability to scale up profit and minimize losses.

5. Speed and Leadtimes

Once the tooling has been completed, Premium Parts can manufacture and ship your parts to your doorstep in as little as 7days. Lesser parts may have even faster lead-times.

Once the tooling has been completed, Premium Parts can manufacture and ship your parts to your doorstep in as little as 7days. Lesser parts may have even faster lead-times.

6. Low-volume and mass production

Injection molding is the most widely-used method for making mass volumes of plastic parts. With low-cost aluminum tooling, injection molding can also be used for prototyping and low-volume manufacturing.

Injection molding is the most widely-used method for making mass volumes of plastic parts. With low-cost aluminum tooling, injection molding can also be used for prototyping and low-volume manufacturing.

7. Rapid prototyping

Injection molding can be used to make quick prototypes for rigorous testing, product marketing, concept validation, and more before expensive mass production investments are undertaken.

Injection molding can be used to make quick prototypes for rigorous testing, product marketing, concept validation, and more before expensive mass production investments are undertaken.

Industries

Our Injection molding services at Premium Parts can serve all of the following sectors:

• Agriculture

• Packaging

• Automotive and Transportation

• Toys

• Medical and Dental

• Aerospace

• Energy

• Robotics

• Electronics

• Industrial

• Consumer products

Injection Molding Materials

Choose from our stock options of production-grade thermoplastics or supply your resin for custom applications. Below are some of our materials for plastic injection molding:

• Plastic, Elastomers, and Synthetic Rubber

• Polyethylene terephthalate (PET)

• Thermoplastic vulcanizates (TPV)

• Polycarbonate (PC)

• Polyolefin Elastomer (POE)

• Polymethyl methacrylate (acrylic) (PMMA)

• High-density polyethylene (HDPE)

• Polyphenylene sulfide (PPS)

• Polypropylene (PP)

• Polystyrene (PS)

• Acetal polyoxymethylene (POM)

• Acrylonitrile butadiene styrene (ABS)

• Low-density polyethylene (LDPE)

• Polybutylene terephthalate (PBT)

• Glass-filled polycarbonate (PC-GF)

• ABS polycarbonate (PC-ABS)

• Nylon 66 (PA66)

• Glass-filled, polyamide (PA-GF)

• Thermoplastic elastomer (TPE)

• Thermoplastic polyurethane (TPU)

• Liquid silicone rubber (LSR)

• Customer-supplied materials

Finishing options

Premium Parts provides an array of finishing services to augment the beauty and cosmetic appearance of your part. We also have finishing options to increase the surface protection of your parts.

• As manufactured

Parts are left as they are when ejected from the mold. Suitable for parts that will be used in closed areas or parts that make up the non-visible portion of a larger component.

• Media blasting

Media blasting uses a medium (sand, bead, glass) to create a surface texture on the molded parts.

• Pad printing

Pad printing is used to transfer logos, graphics, and texts to the surface of the part.

• Etching

Etching can be used when looking to make a marking or inscription on a molded part’s surface.

• Polishing

Premium Parts can achieve glossy, semi-glossy, matter, and mirror-like finishing on your part by polishing and sandpapering the part as desired.

• Texturing

Texturing can enhance grip, grab, and hold functionality for molded parts.

• Painting

Injection-molded parts may be wet-painted, or powder-coated in an array of color and texture-rich automotive-grade paints.

• Custom

Choose from an array of custom finishing that is unique or a combination of some standard finishes.

Plastic Injection Molding FAQs

1. What plastics do you work with for Injection Molding?

At Premium Parts, we work with high-quality varieties of engineering-grade thermoplastics. Virtually every type of thermoplastic can be processed into final parts.

2. What are the benefits of Plastic Injection Molding?

Plastic injection-molded parts have a great cosmetic appearance, dimensional accuracy, strength, and high-performance. When making large volumes of plastic parts, injection molding is the most cost-effective solution.

3. How long does it take to make my mold?

Depending on how many parts will be made from the mold, the mold’s design complexity, and the material to be used for the mold, tooling can take anywhere between 3 to 14 days to produce.

4. When can I receive the DFM for my part?

We can offer the DFM free of cost with quote sending.

5. How can you ensure my part can work as specified?

Before running full of the order, we would send our clients 3-5 parts for testing or confirmation. We would only mold all the parts after getting approval from our client. If the initial units are out of expectations, we would keep fixing the tool until parts are accepted by our customers.

6. Can I supply my plastics for molding?

Sure, you can supply your plastics for part molding. Please also check with us to ensure that is in our capability.

Enjoy concurrent product quality across all production scales from 1 to 10,000+ parts.

Enjoy concurrent product quality across all production scales from 1 to 10,000+ parts.

Once the tooling has been completed, Premium Parts can manufacture and ship your parts to your doorstep in as little as 7days. Lesser parts may have even faster lead-times.

Once the tooling has been completed, Premium Parts can manufacture and ship your parts to your doorstep in as little as 7days. Lesser parts may have even faster lead-times. Injection molding is the most widely-used method for making mass volumes of plastic parts. With low-cost aluminum tooling, injection molding can also be used for prototyping and low-volume manufacturing.

Injection molding is the most widely-used method for making mass volumes of plastic parts. With low-cost aluminum tooling, injection molding can also be used for prototyping and low-volume manufacturing. Injection molding can be used to make quick prototypes for rigorous testing, product marketing, concept validation, and more before expensive mass production investments are undertaken.

Injection molding can be used to make quick prototypes for rigorous testing, product marketing, concept validation, and more before expensive mass production investments are undertaken.