What is 5-Axis Machining?

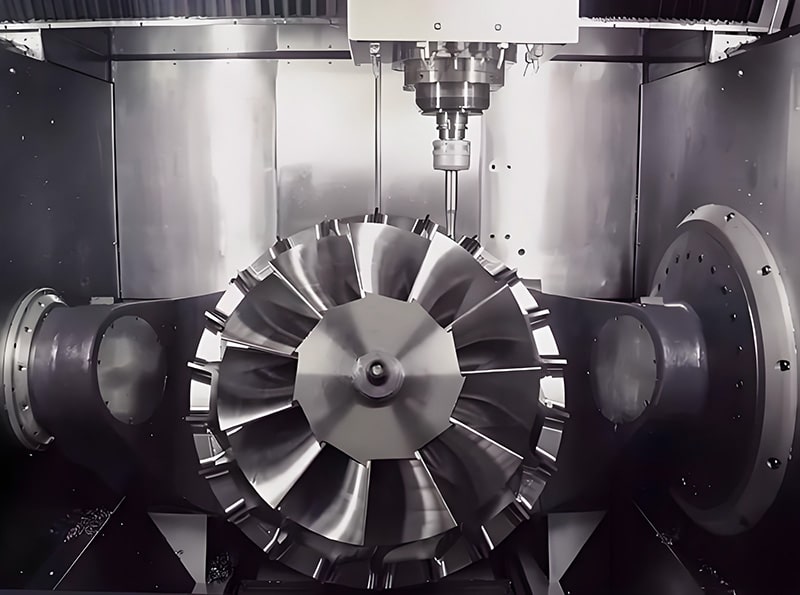

5-axis machining uses a simultaneous motion of cutting tools or parts along five axes utilizing a computer numerical control (CNC). Every cutting tool's axis is constantly moving to align the cutting tip to the component. This process effectively manufactures various complex parts with extreme accuracy in any shape or size.

Traditionally, machines have often been either one-axis (such as a drill that only operates up and down on the y-axis) or three-axis (a machine that can run up and down on the y-axis, left and right on the x-axis, and forward and back on the z-axis). For 5-axis machining, the user gets two additional axes: A-axis (the tilting table) and C-axis (the table rotation).

How does 5-Axis Machining work?

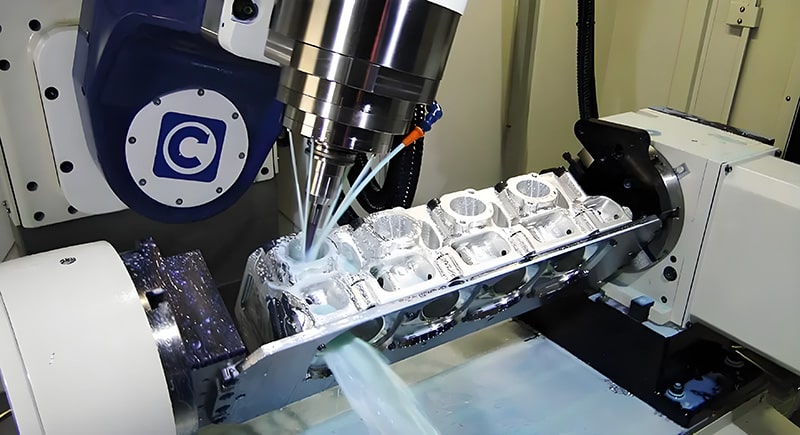

The work piece is manufactured to its desired shape in CNC machining using high-quality cutting tools and subtractive machining technology. The original CAD (Computer-Aided Design) file predetermines the form. Afterward, a program in G-Code format is created, feeding the CNC machine with instructions.

Presently, three axes—X, Y, and Z—are most commonly used for CNC milling machines. However, 5-axis CNC machines use extra axes to incorporate cutting from different angles, allowing them to manufacture more complex and intricate patterns. As a result, axes A, B, and C can be shown. These axes coordinate with X, Y, and Z in rotating angles to produce a 5-axis cutting machine capable of complex designs while maintaining a high standard for the final product. The A, B, and C axes rotate independently from the X, Y, and Z axes. It depends on the specific machine setup or CAD design to determine which two of the other three rotating axes are used. Due to the greater degrees of automation and calibration technologies required to operate the CNC machine and input commands, this 5-axis setup can be more expensive. Premium Part's 5-axis machining is a major engineering technology in the automotive, aerospace, and medical industries, among many others, and can provide the best precise engineering solutions.