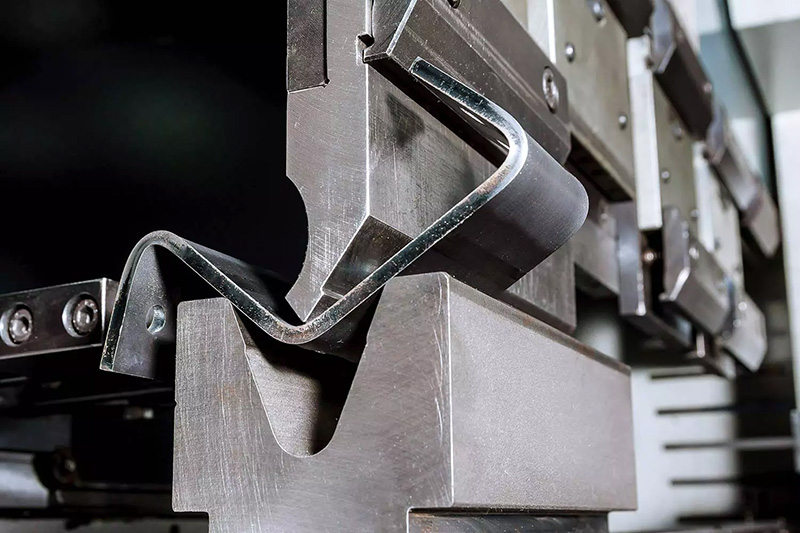

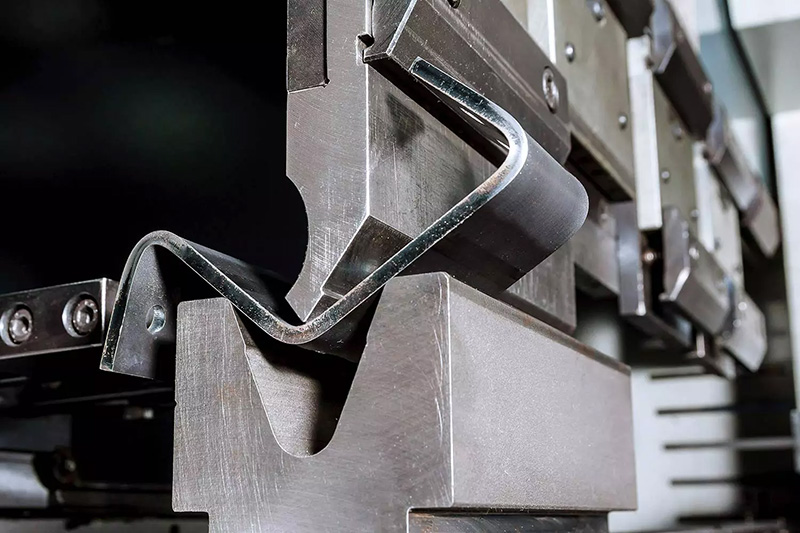

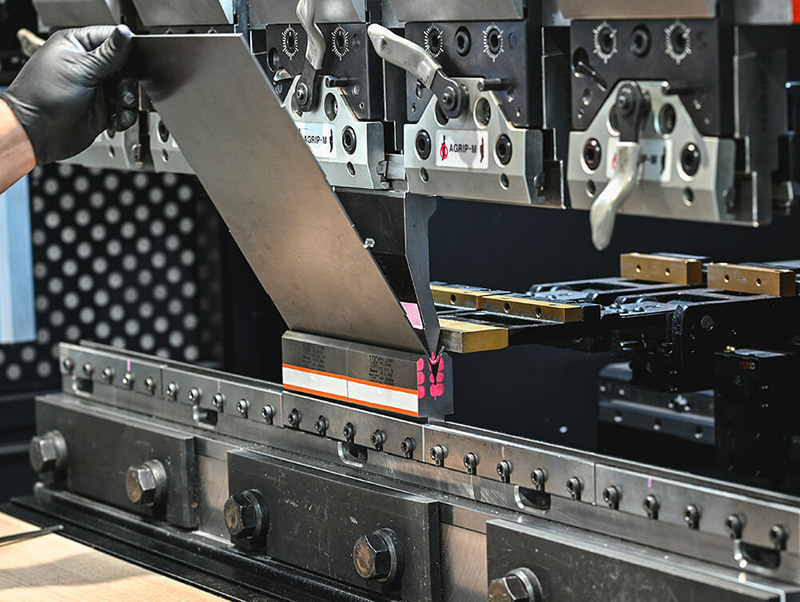

Precision and Reliability with different shape of metal bending

Premium Parts offers top notch metal bending services of highest industrial standards. With over 15 years of experience in sheet metal manufacturing, we serve a great range of industries that includes the automotive, aerospace, medical, and consumer electronics. Our state-of-the-art CNC Metal Bending tools at our faculty in Dongguan, China has the peak capability of delivering precise custom metal bending solutions. We use a variety of materials - aluminum, steel, copper and brass to meet your various requirement.