What Is Insert Molding?

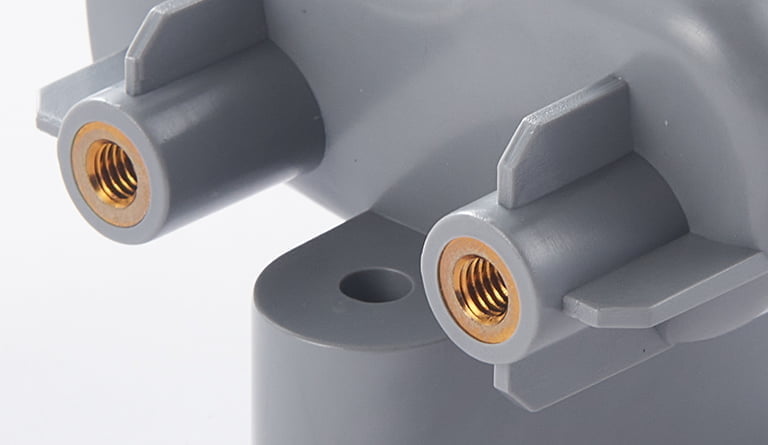

In insert molding, a pre-formed part called an insert is put into a mold hole. After that, plastic is pumped around it. When the plastic cools and forms, it joins with the insert to make a single piece. It makes a strong bond because of this. The part could be made of metal, plastic, or something else. It's often used as a helpful part, like an electrical connector.

The best parts of different materials are combined to make a single product. So, it enhances strength or usefulness while reducing assembly stages and costs. Insert molding is an advanced manufacturing process that Premium Parts specializes in. Premium Parts use this method to make plastic parts harder, more practical, and last longer.

It is the best way to place metal hardware when working with plastic parts. Such hardware can be bushings, plastic parts, or electrical links. Using insert molding, Premium Parts can manufacture complex components.