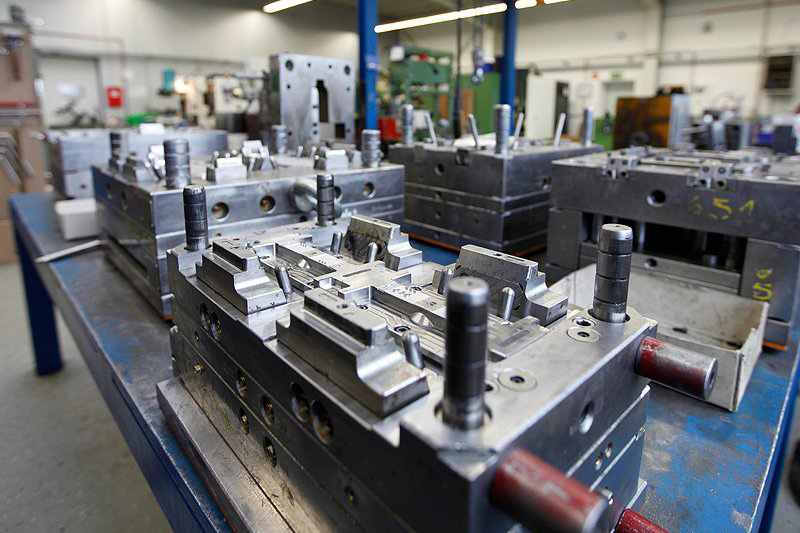

High-quality mold-making services for mass production plastics and metals.

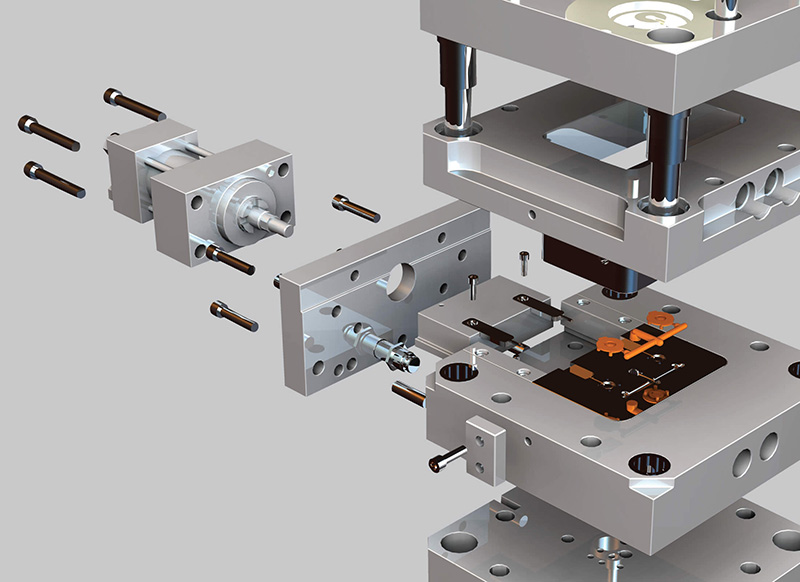

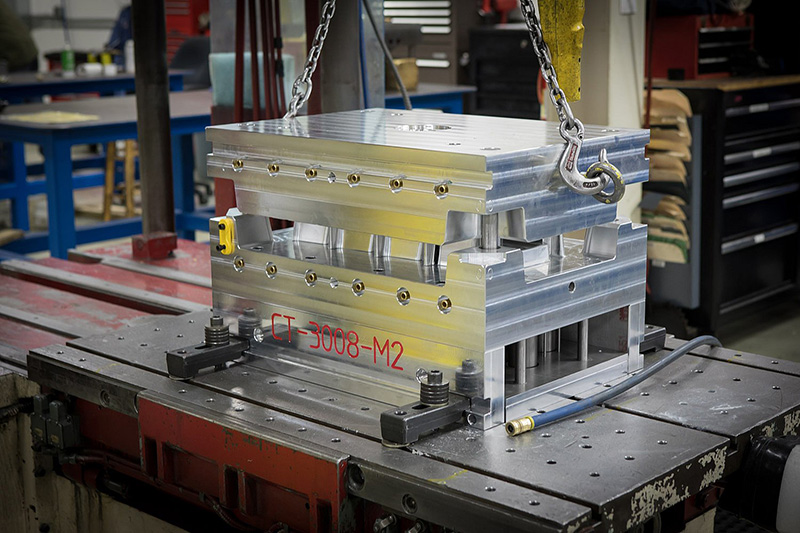

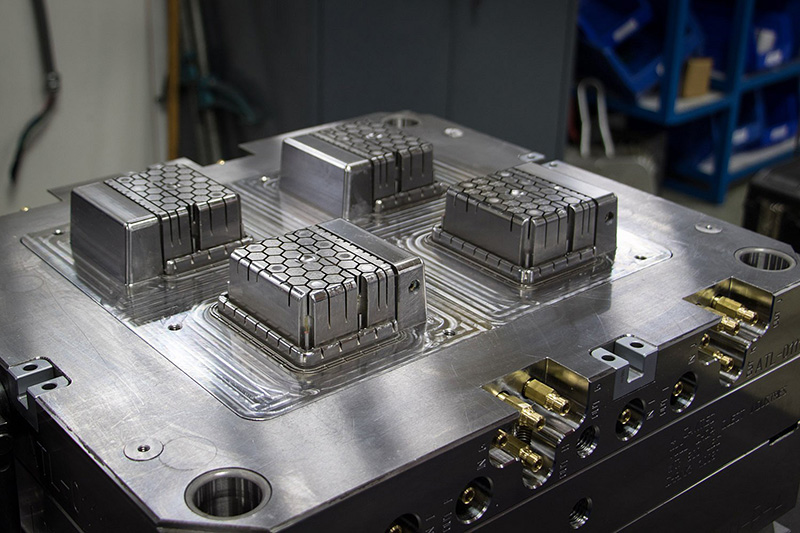

Premium Parts provides high-quality mold-making services catering a wide range of industries. Our molding services in China engulf molds for metal casting, plastic injection, and custom CNC molds. Our in house capabilities with a wide network of partners strive hard to provide tailored solutions.

If you need prototype molds for short production runs to robust molds designed for mass production, Premium Parts has a seasoned team to produce molds with seamless process. Our turnaround times are quick and we also incorporate different materials such as aluminum, steel, and plastic.