What is 3D Printing

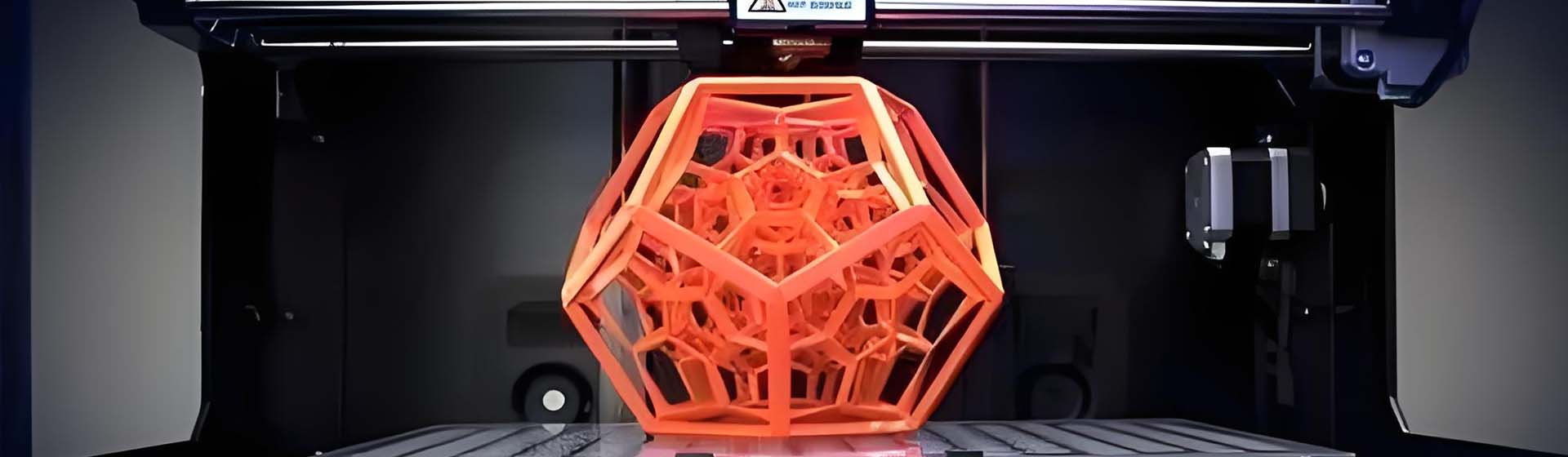

3D Printing, alternatively termed “additive manufacturing,” is a production technique used to produce quality products and low-volume parts by printing a digital-model, computer-aided-design file (CAD), layer by layer, into a physical 3-dimensional object. The printing is achieved with a material, which may be plastic, metal, or a composite. At Premium Part, our industrial 3D printing capabilities provides you with an array of services suitable for the various stage of your product development cycle, allowing you to advance from prototype to final product in as little as 48 – 72 hours.

Understanding our 3D Printing Solutions

At Premium Parts, our industrial 3D printing services are mainly focused on selective laser sintering (SLS), Fused deposition modeling (FDM), Direct metal laser sintering (DMLS), and stereolithography (SLA).

• Direct Metal Laser Sintering (DMLS) & Selective Laser Melting (SLM)

DMLS uses a powerful combination of a fiber-laser system and atomized powder to create fully functional metal parts that can serve automotive, aerospace, and even medical industries. Both of these technologies are similar to SLS, but while SLS isn’t used for metallic parts, DMLS and SLM are used to produce parts from single element materials and metal alloys.

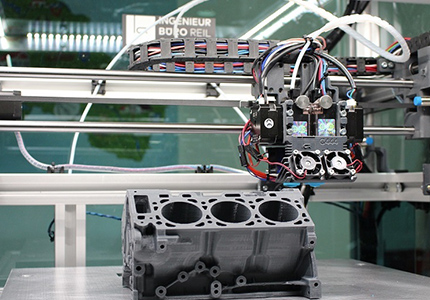

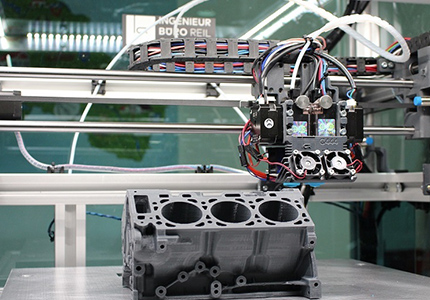

• Fused Deposition Modelling (FDM)

FDM is arguably the most widely used additive manufacturing technology used for design validation and low-volume production. FDM uses affordable plastic filaments to make parts for idea validation and quick prototyping. FDM parts may not have tight tolerances and excellent surface texture post-print.

• Stereolithography (SLA)

SLA is an efficient 3D printing technique that uses a UV laser to cure liquid thermoset resin and form production-grade parts. SLA is ideal for projects where visual appeal is crucial, and injection-mold-like finishes are desired.

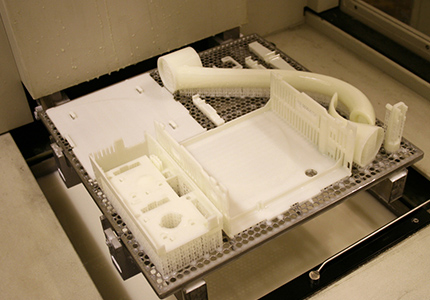

• Selective Laser Sintering (SLS)

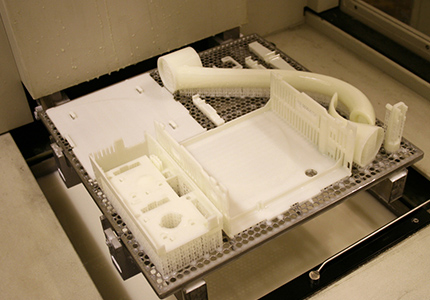

SLS is used to create finely fused thermoplastic parts that boast excellent mechanical and functional attributes. SLS parts are made by directing a laser, which acts as a power source towards powdered material at points dictated by the 3D CAD model.

Why You Should Choose 3D Printing

• Shorter lead-times

3D printing can manufacture prototypes and parts in as fast as 24 – 72 hours. This is because 3D printing requires no tooling or complicated fixture, and produces end parts based on a simple design file called the computer-aided-design (CAD).

• Cost-effectiveness

3D printing is part of the most cost-effective solutions for making one-off parts or small batches of production runs that will require expensive tooling through other manufacturing techniques.

• Intricate features and geometries

Because of the CAD file’s design flexibility and the layer-by-layer processing technique of 3D printers, additive manufacturing solutions can achieve the part design and geometric complexities near-impossible with other methods.

• Low-waste process

3D printing makes parts layer by layer, from the ground up. Unlike CNC machining and other subtractive processes, 3D printing uses only the required material volume for a print operation. This helps businesses to manage costs and reduce waste.

• Flexibility

3D printing enables on-the-go corrections to design and easy modification of part geometries. By simply editing the CAD file, engineers can incorporate design changes into their parts and re-print their parts. This contrasts with other production techniques that use hard tooling investments.

Applications of 3D Printing

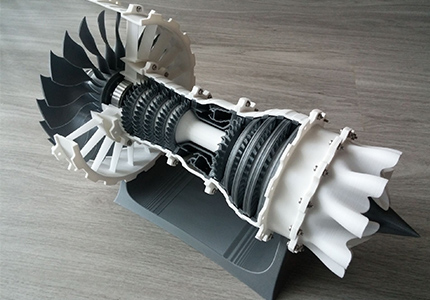

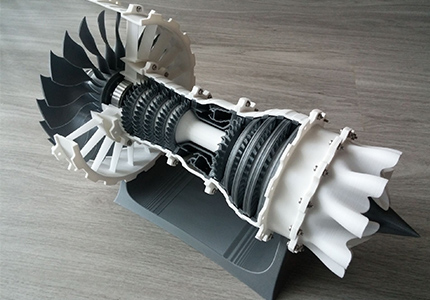

• Complex design projects

3D printing is used for making parts with complex geometries, features, and components.

• Rapid prototyping

3D plays a crucial role in most rapid prototyping techniques by allowing the leverage of the CAD file to print product prototypes right from the desktop. 3D printing is also used in making the master pattern for vacuum casting, a prototyping technique that produces parts with a good cosmetic appearance.

• Rapid tooling

3D printing and computer-aided design (CAD) are used for mold design and quick tooling of complex production components at affordable cost and shorter lead times.

• Low-volume production

Our 3D printing is suitable for low-volume production and making parts in small batches for various end-uses and applications.

Industries

3D printing is used across several industries for rapid prototyping, quick production, and small-batch manufacturing. Here are some of the sectors that Premium Parts’ 3D printing services can serve:

• Toys

• Agriculture

• R&D

• Packaging

• Architecture

• Electronics and semiconductors

• Consumer products

• Construction

• Energy and power

• Automotive

• Robotics

• Medical and Dental

• Aerospace

3D Printing Materials

The diversity and versatility of additive manufacturing make it compatible with an array of materials. At Premium Parts, our SLS, SLA, DMLS, and FDM printers can manufacture simple and complex parts from plastics and metals. Here are some examples of materials we work with:

• Plastics

Premium Parts can print engineering-grade thermoplastics like ABS or Nylon.

• Metals

We can 3D print metals for high-strength, low-weight, and high-performance applications in low-volume productions. Our metal options include stainless steel, aluminum, and titanium.

Finishing options

At Premium Parts, our 3D-printed parts can be finished in various options. Our finishing solutions for additive manufacturing include:

• Standard

• Media blasting

• Polishing

• Sanding

• Brushing

• Painting

• Silk printing

• Plating

• Texturing

Why Choose Us

• Dedicated process

Our 3D printing operations follow a reliable process flow that helps us mitigate risk, vet raw materials, and produce quality prototypes and end-parts every time.

Our 3D printing operations follow a reliable process flow that helps us mitigate risk, vet raw materials, and produce quality prototypes and end-parts every time.

• Scalability and repeatability

Our additive manufacturing solutions are scalable and repeatable, allowing you to prototype or manufacture around your budget without compromising print quality.

Our additive manufacturing solutions are scalable and repeatable, allowing you to prototype or manufacture around your budget without compromising print quality.

• Finishing services

Premium Parts can offer post-printing solutions to beautify and enhance your part’s cosmetic appearance after manufacturing. Our in-house finishing is done under the same quality control umbrella for a lasting guarantee of quality.

Premium Parts can offer post-printing solutions to beautify and enhance your part’s cosmetic appearance after manufacturing. Our in-house finishing is done under the same quality control umbrella for a lasting guarantee of quality.

• Speed

The industrial capacity of our 3D printers will help you accelerate your product development cycles and get to your target market quicker and better. We can also help you leapfrog bottlenecks and jump right into product developments right away.

The industrial capacity of our 3D printers will help you accelerate your product development cycles and get to your target market quicker and better. We can also help you leapfrog bottlenecks and jump right into product developments right away.

Request A Quote

Getting started with Premium Parts is easy. We invite you to explore our expertise and machine capabilities to make quality prototypes and custom end-use parts on-demand with our 3D printing services. Choose from SLA to SLS, FDM, and DMLS to quickly and affordably create your parts in production-grade materials. Our one-stop-shop finishing options will augment your part design and enhance functionality.

3D printing FAQs

1. What is the largest size of a part you can print?

For now, the largest size we can print is 800x600x400(mm). Please also be aware that the part would be less precise with a bigger size.

2. What’s the thinnest thin wall you can print?

The thinnest thin wall we are available to print is 1mm.

3. How’s strong of the printing units?

Generally, we will evaluate the possibility to print the giving part size and strength to use. If the part is not suitable for 3D printing, we will let our clients know.

4. Can you print the parts with high precision?

3D printing is a low-precision manufacturing process compared to CNC machining. If you want parts to be high precision, CNC machining will be preferred.

5. What kind of parts are good for 3D printing?

Some parts with less precision required, used for parts fitting purpose or proofing the concept.

Our 3D printing operations follow a reliable process flow that helps us mitigate risk, vet raw materials, and produce quality prototypes and end-parts every time.

Our 3D printing operations follow a reliable process flow that helps us mitigate risk, vet raw materials, and produce quality prototypes and end-parts every time. Our additive manufacturing solutions are scalable and repeatable, allowing you to prototype or manufacture around your budget without compromising print quality.

Our additive manufacturing solutions are scalable and repeatable, allowing you to prototype or manufacture around your budget without compromising print quality. Premium Parts can offer post-printing solutions to beautify and enhance your part’s cosmetic appearance after manufacturing. Our in-house finishing is done under the same quality control umbrella for a lasting guarantee of quality.

Premium Parts can offer post-printing solutions to beautify and enhance your part’s cosmetic appearance after manufacturing. Our in-house finishing is done under the same quality control umbrella for a lasting guarantee of quality. The industrial capacity of our 3D printers will help you accelerate your product development cycles and get to your target market quicker and better. We can also help you leapfrog bottlenecks and jump right into product developments right away.

The industrial capacity of our 3D printers will help you accelerate your product development cycles and get to your target market quicker and better. We can also help you leapfrog bottlenecks and jump right into product developments right away.