To select the optimum threading technique, it’s important to understand the benefits of each option. Hand tapping offers a manual solution. It’s best for low throughput use. Moreover, it provides accuracy, and exact precision in small-scale production settings. On the other hand, machining threads makes it easier to produce a bulk volume of products.

Using CNC machines provides greater control over thread uniformity than hand tapping. However, each process has its features, and benefits depending on the parts size, complexity, material types, and production goals.

You can make a selection based on the work’s difficulty and the desired output. In addition, to choose between hand tapping vs machining thread, you can also consider factors like speed, precision, and cost. In this article, we will provide you with a few fundamental aspects to use between hand tapping or machining thread.

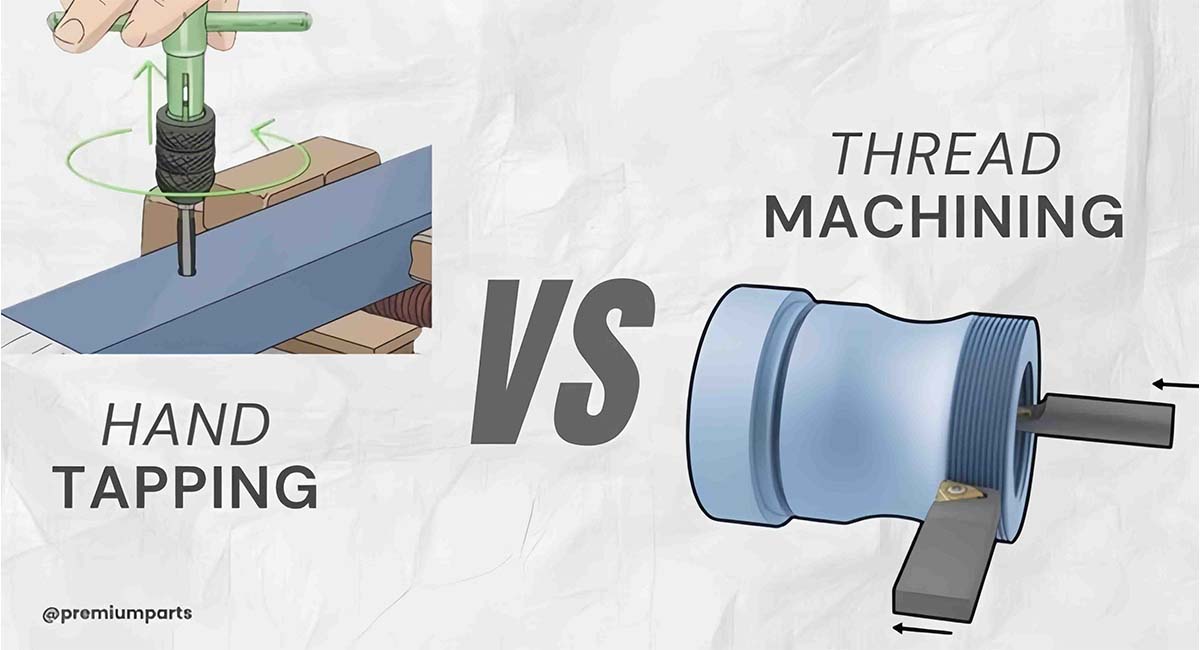

Hand Tapping Vs Machining Threads: Detailed Process Overview

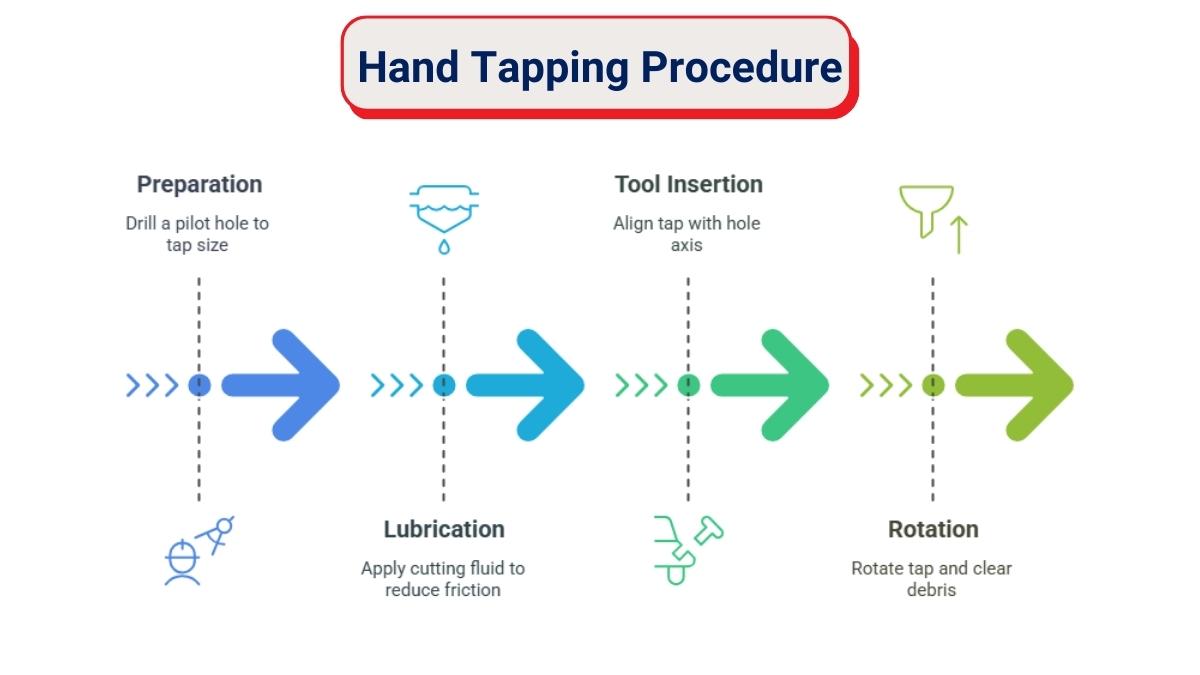

Hand Tapping Process:

Infographic on Hand Tapping Process

Image Description: An image showing the step-by-step procedure of the hand tapping process. The sequence begins with a secured workpiece, followed by drilling a hole. Next, the hole is chamfered, and a tap is aligned using a tap wrench.

You can use tapping to shape internal threads in a pre-drilled hole. The process entails a tap to insert it into the hole. You simply rotate the tap to make the threads. The following steps outline the hand-tapping procedure:

- Preparation: First, drill a pilot hole right to the size of the tap. Then, match its diameter all the way. The hole depth has to be equal to the thread depth as required.

- Lubrication: Use cutting fluid or lubricatives to help minimize friction and heat effects and to get a clean cut. Lubrication protects the tap and helps produce a better-quality thread finish.

- Tool Insertion: After applying coolants, tap into the hole, directing right up and down with the surface. You must align the tap with the hole axis for better thread accuracy.

- Rotation: Start rotating the tap by your hand in a clockwise direction to thread the tap. Occasionally, reverse the tap to back it out and clear any debris that could cause binding. Then, slightly withdraw the tap when you reach the required depth.

Hand tapping is most effective for small quantities, first runs, and where access to power tapping equipment is not obtainable.

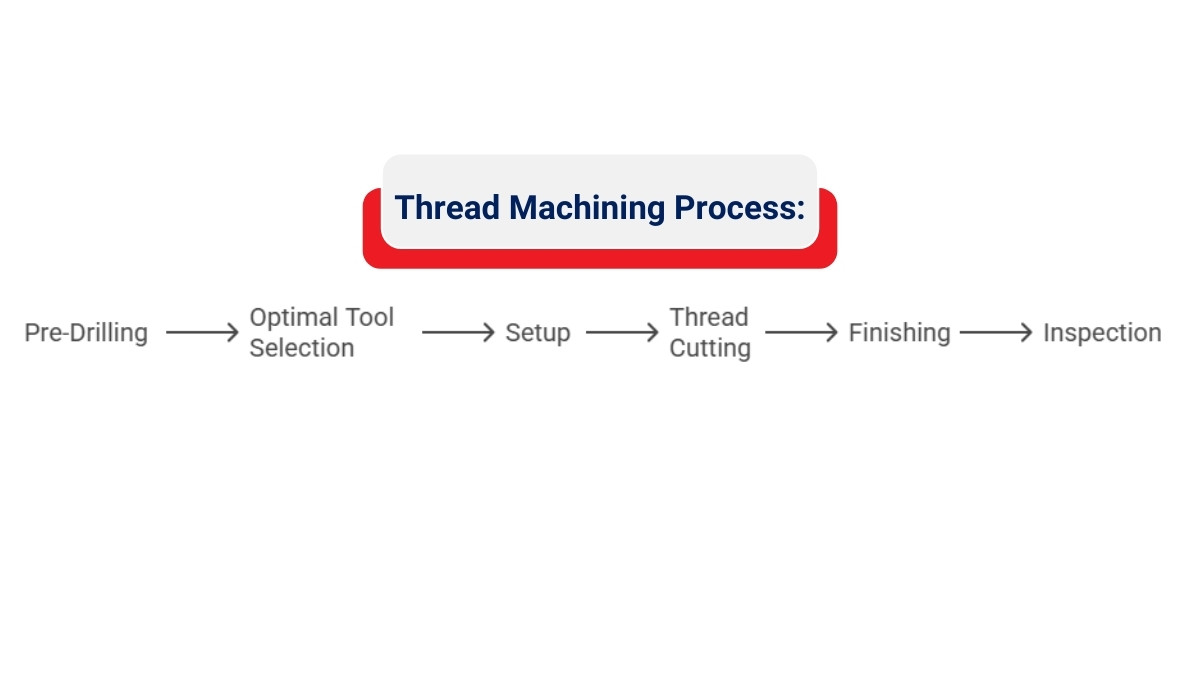

Machining Threads Process:

Thread Machining Process

Image Description: An image depicting the thread machining process. It shows a sequential procedure on how to form precise threads. The process includes coolant application, controlled cutting, tool retraction, and final thread inspection using a gauge or bolt.

CNC machines or lathes are typically employed to machine highly accurate threads. These are suitable for mass production runs. Automated tools are used to cut threads, offering greater precision in the process. Here’s how machining threads is generally done:

- Pre-Drilling: First, drill a hole that fits the size needed for threading. Choose the right tap drill size to achieve accurate threading for the threading tool.

- Optimal Tool Selection: Based on the type of threads, choose an appropriate threading insert or tool, such as metric or imperial. CNC machines use single-point threading or thread milling.

- Set Up: Transfer the workpiece into the CNC machine or lathe work. Ensure the tool is well located and the machine is correctly adjusted for the thread size and depth.

- Thread Cutting: Start the CNC program or turn the lathe to thread-cutting mode if you are not using the CNC program. Normally, the tool rotates in a helical motion around the central spire of the hole, and with each run, it cuts out material to make the thread shape.

- Finishing: Usually, one pass is sufficient. But to achieve the required depth, diameter, and surface quality, several finishing passes are made.

- Inspection: For thread accuracy check, use plug gauges and thread pitch gauges as per necessity. CNC systems may incorporate some sort of sensor to inspect the thread quality at the time of manufacturing.

Thread machining is optimum on a large scale since it is more efficient than hand tapping.

Similarities Between Hand Tapping vs Machining Threads

Even though hand tapping vs machining threads differ in terms of the equipment used as well as the application, the general procedure and purpose of the two are almost alike. Here are the key similarities:

- Thread Formation: Both are employed for making internal threads in a pre-tapped hole. Either manually or mechanically, the goal is to create threads that would be able to mesh with a screw, bolt, and fastener.

- Pre-Drilled Hole: These processes both start with the use of drilling to make a hole to the right diameter. The hole size for the threading operation should correspond to the thread type and the tap or the threading instrument.

- Lubrication: Machining threads are similar to hand tapping as both are enhanced by using cutting fluids or lubricants. Cooling alleviates the heat that builds up between the tool and the workpiece and smoothes the thread by reducing friction.

- Thread Profile: In both techniques, the purpose is the same: to produce a specific thread profile, for example, metric or imperial threads. This helps the company match the right screws, bolts, and other fasteners for assembling the part.

- Tool Selection: Each of the two methods demands particular tools for cutting out the thread. Hand-tapping tools are called tap tools, and machining tools are called cutting tools or thread mills. While the tools differ, they all serve the same purpose: to cut and shape the threads.

- Thread Depth and Length Control: In both methods, the operators manually control the thread depth for the right length and thread depth. It’s also essential to locate the proper engagement of the threaded hole.

- Accuracy and Quality: In both processes, thread gauges or calipers may be used to check the finished threads for pitch diameter, diameter, and tolerance, respectively.

What Is a Screw Tap?

Screw Tapping

Image Description: An image of the Screw Tapping process. It displays a tap cutting internal threads into a pre-drilled hole in a workpiece.

A screw tap cuts internal threads in a hole for screws or bolts. A cutting tool rotates and cuts threads into the hole, which is why manufacturers call the process tapping.

Here’s how it works:

- Drill a Hole: As a preliminary step, you must first make a hole of the appropriate diameter with a drill. It should be slightly smaller than the screw diameter in question. Push the tap to cut the threads that the screw will fit into.

- Apply the Tap: A tap is fitted into the hole, and by turning it with a wrench or a tapping machine, it buries new threads into the hole. Taps are available in diverse types to suit the thread forms, which include the metric or imperial forms of threads.

Types of Taps:

Types of Taps

Image Description: An image displaying different types of taps used for threading, including hand taps, spiral point taps, spiral flute taps, and forming taps.

- Taper Tap: Includes a progressive taper to assist in starting the threading operation and to ease the tool in the hole.

- Plug Tap: People usually use it after the taper tap. It can finish and extend the threads, especially in deep holes.

- Bottoming Tap: Applicable when creating a thread at the base of the hole. In addition, when you cannot thread the hole all the way.

Tapping is a practice in metalworking, woodworking, and other industries to cut thread for screws such as bolts, screws, and machine components.

When to Choose Thread Machining Over Hand Tapping: Key Considerations for Optimal Threading Performance

Here are several key factors to consider when deciding between thread milling vs hand tapping:

1. Material Type

- Harder Materials: Apply thread milling to harder materials like stainless steel, titanium, or high-strength alloys. Because it avoids high temperatures and stresses on the tool. Hand Tapping, specifically, when done with harder materials, results in tool breakage and, and most cases, thread distortion.

- Brittle or Fragile Materials: In brittle materials (like castings or certain plastics), thread milling can be used instead of hand tapping because if the wrong type of tap is used on the material, the threads may strip or crack.

2. Hole Depth

- Deep Holes: Thread machining is especially effective when making deep or blind holes in which tapping may be impracticable. With tapping, the hole length can dictate the level of threading possible to be accomplished, and chip removal can be an issue. Moreover, thread milling can create a thread at any depth of the workpiece with better chip control when compared with manual tapping.

- Shallow Holes: For small diameter holes, tapping is usually more rapid and easier to install than drilling.

3. Thread Quality and Precision

- Tighter Tolerances: Use thread milling for tight-tolerance applications. Since the process creates cleaner, more precise threads with uniform finishes than tapping, it tends to produce uneven threads because of tap variations in the material.

- Multi-start Threads: Thread machining can create multi-start threads, which is impossible when using traditional tapping techniques.

4. Thread Type

- Complex or Non-Standard Threads: Thread machining can be a better option when you require threads with interesting profiles, such as metric threads, custom thread forms, or multi-start threads. You can use hand tapping for standard threads like UNC/UNF or metric types.

- Standard Threads: Turning is optimum for generating frequent, simple types of thread.

5. Machine Setup and Adaptability

- CNC Machining: Thread milling is highly suitable for CNC machines. It may run on several materials and part geometries. Threading, which is quite often, features several operations such as face milling, boring, and thread milling in a single cycle.

- Tapping Machines: Hand Tapping can be carried out with a tapping machine, CNC, or manually, but usually, more specific tool settings are needed. Especially for deep or blind hole tapping.

6. Chip Removal

- Thread Machining: Another benefit of thread milling is its ability to better control chip formation. The machine removes chips, reducing tool damage and improving surface finishes.

- Tapping: Tapping can make it difficult to remove chips in deep holes that, in turn, cause tool jamming or even tool breakage. They are also more likely to have problems with chip packing and clogging, especially in materials that make long string chips.

7. Cycle Time and Efficiency

- Tapping: Tapping is generally faster for short production runs. In addition, it is less complicated and requires considerably shorter cycles to perform.

- Thread Milling: Thread milling may take more time than tapping. Specifically, in producing standard threads, although it may prove faster in some instances, especially for difficult material where multiple passes and tool changeovers are likely to happen in tapping.

8. Tool Cost and Availability

- Tapping Tools: Tapping tools are fairly affordable and easy to acquire. For small and medium-volume production, they may be the best solution.

- Thread Milling Tools: In contrast, threading tools are slightly more expensive; they can perform several operations for example, producing several threads and creating a chamfer, in a single pass. For larger and more complicated jobs, while it may cost more to use the tools, there will be less need for tool change or additional setups.

9. Hole Size and Hole Access

- Blind Holes or Tight Spaces: Thread milling works better when access to the hole is restricted. The use of the tap in confined areas may be more difficult or less precise to make the tap effectively interact with the material.

- Through Holes: Hand tapping usually completes through holes with standard thread demands faster.

10. Tool Flexibility

- Multiple Thread Sizes: Customization is a major advantage of thread milling. You can easily change from one type of thread or size to another without any tool changeover. It’s quite helpful, particularly when you need to produce many threads of the same type or different sizes.

- Tapping: Use a different tap for each thread size. This requires several taps for different tasks. Thereby raising the cost of tools and organizational issues.

Conclusion:

In conclusion, use hand taps and machining threads for light-duty tasks and small parts. For cases where the simplicity of use is more significant than the rate of work and accuracy. They are popular when performing maintenance and making repairs. However, hand taps are relatively slow and less precise than machine taps, thus optimum for low production and site use.

In comparison, use machine threads for mass production where speed and process standardization are important to your project. They run on high-precision CNC machines or tapping machines. Therefore, it is ideal for industrial applications where higher production rates and tighter tolerances are utmost. Machine taps are more long-lasting and can produce finer cuts.

If you want the best threads, consider buying high-quality parts from Premium Parts. We welcome you to contact us today to learn more about our superior tapping solutions for your business.