CNC software is the brain for any modern product manufacturing operation. As an engineer, machinist, or manufacturer, you must understand how important it is to select the best tool for your application. But with so many software options, how can you determine which one will get the desired precision and output? It’s not that difficult. Knowing the needs of your job is the key. Whether you are making simple parts, simulating any tool, or finalizing the best material, the right tool will help you achieve all this in minimal time.

In this guide, we will discuss the normal operation of CNC software, key types, and its applications. By getting insights into their key features, pros, and potential applications, you can select the best one for your work quickly. Ready to understand the world of CNC software? Let’s get into it.

What is CNC software?

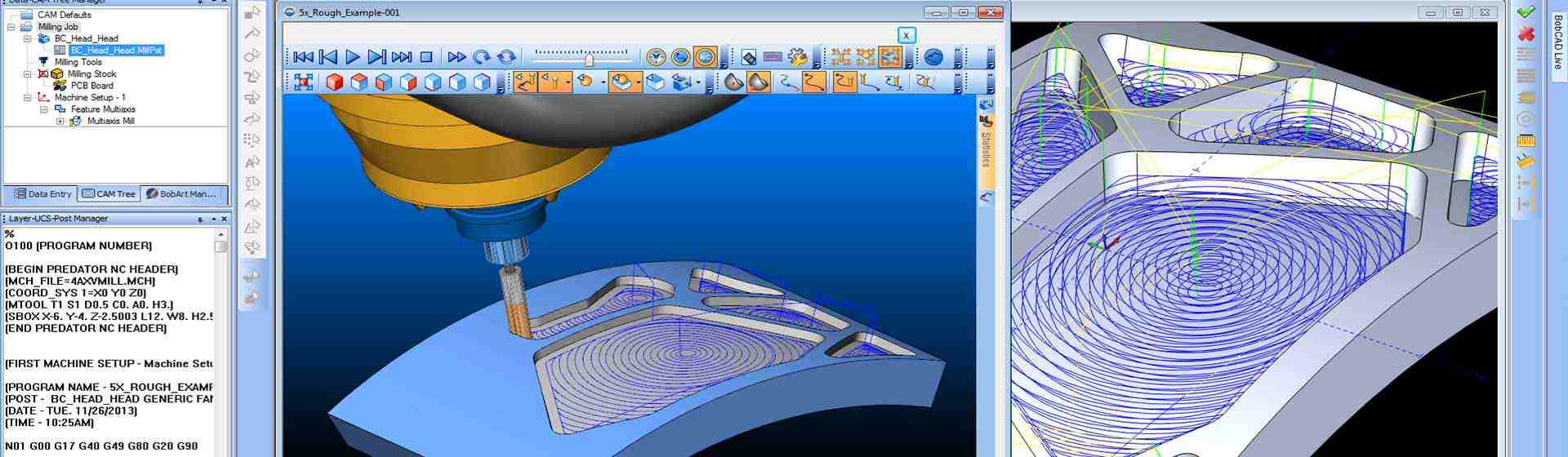

SolidWorks virtual machining simulation

Image Description: A detailed view of SolidWorks CAM virtual machining simulation. The interface displays a 3D part with toolpaths generated for CNC milling/turning.

CNC software is the tool to communicate with CNC machines, including milling, drilling, cutting, and lathe, etc., to control and optimize their operation. You can use this software to convert machine operations into digital code. The code, also termed G-code, commands the attached machine to work accordingly. In other words, it’s a code in machine language.

Such software comes in various types, including CAD (for making parts), CAM (for creating the tool paths to the machine), and CNC (to direct the machine operations). Selecting the right software tool is compulsory for optimizing your work and getting maximum quality.

G-Code (Geometric Code)

G-code is the language that the machine speaks. Designers use this code to tell machines how to cut, move, and perform related operations. Consider it as guidelines attached machine that follows to convert any raw workpiece into a desired part. The command for each G-code is specific. These codes encompass detailed information related to tool movement, including cutting depth, feed rate, tool approach angle, and others. The code is first generated in CAM software, based on the design. Then, it is fed into CNC software to perform the intended task. If this code is not accurate, you can lose your time as well as material. So, understanding the code is as important as the right selection of other factors.

Types of CNC Software

The accurate application of CNC software enables companies to maximize production speed while improving quality and lowering operational stoppages. The software that you select before design begins remains vital throughout your manufacturing process. Although there are numerous CNC software programs utilized for different applications. Here, we will discuss each category one by one.

CAD (Computer-Aided Design) Software Types

CAD software helps in performing CNC machining tasks by making their 2 or 3-dimensional models. These digital models act as a foundation for accurate machining, confirming efficiency in the coming operations. Major CAD software is:

Fusion 360

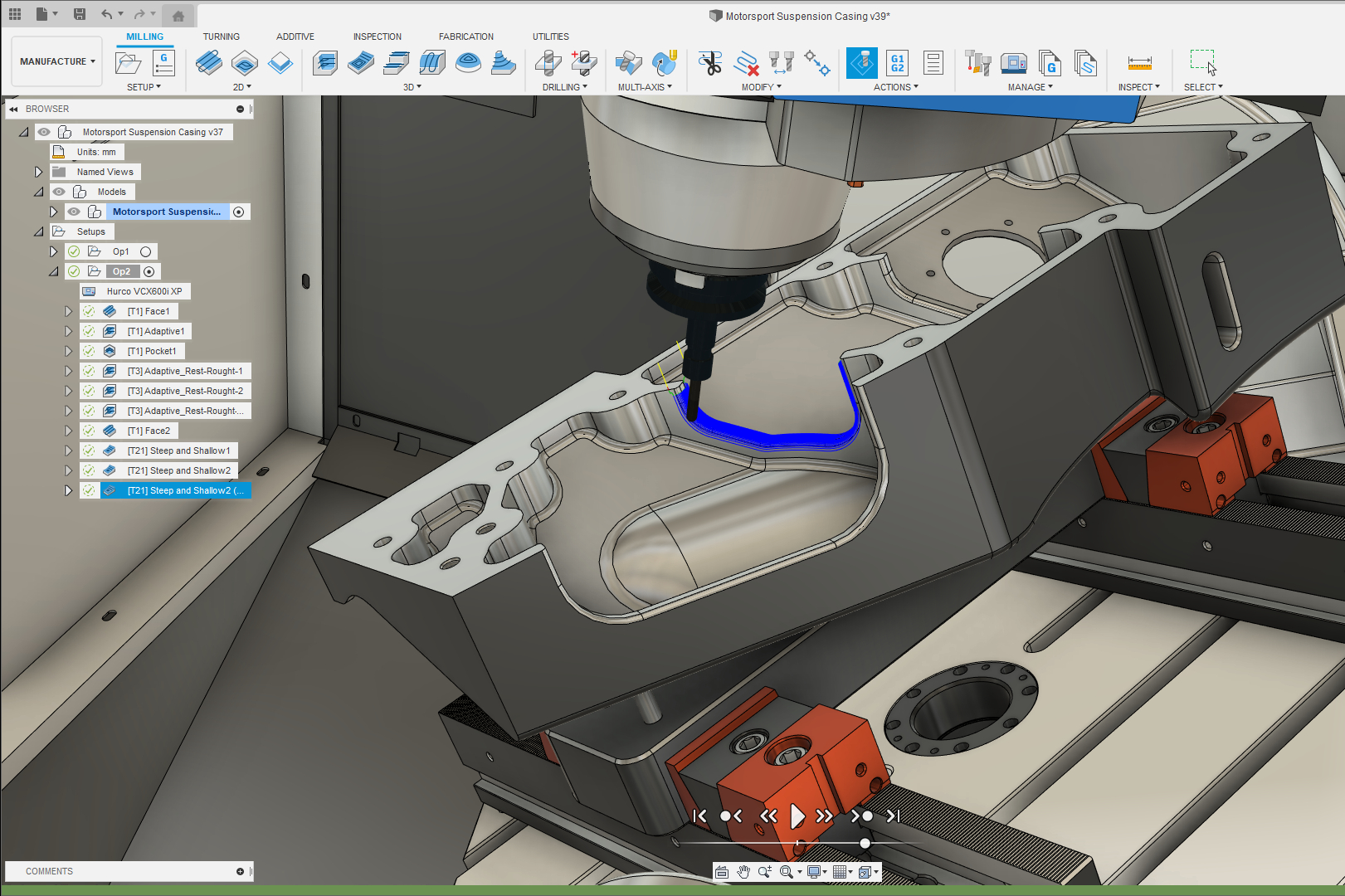

Fusion 360 CAM Simulation

Image Description: A screenshot of Autodesk Fusion 360 displaying a CNC machining toolpath. The interface shows the 3D part, toolpath lines, and machining settings used for CAM programming.

Fusion 360 provides software integration that joins 3D design functions together with engineering capabilities and simulation tools. The cloud-based collaboration platform provides excellent functionality for teams tackling complex projects together. Through its parametric and direct modeling functions, the model allows users to design complex parts that can be immediately verified by real-time simulations. In addition, the application enables you to use generative design technology for creating parts. Through this, designers achieve optimal functionality alongside maximum efficiency. The software integrates perfectly with manufacturing tools to enable a smooth production workflow. Integration shortens the time needed to turn ideas into actual manufactured product configurations.

Applications:

- Users generate product models and prototypes through 3D design.

- Structural and thermal analysis of components.

- The system allows for complete integration with CAM software tools used in manufacturing operations.

SolidWorks

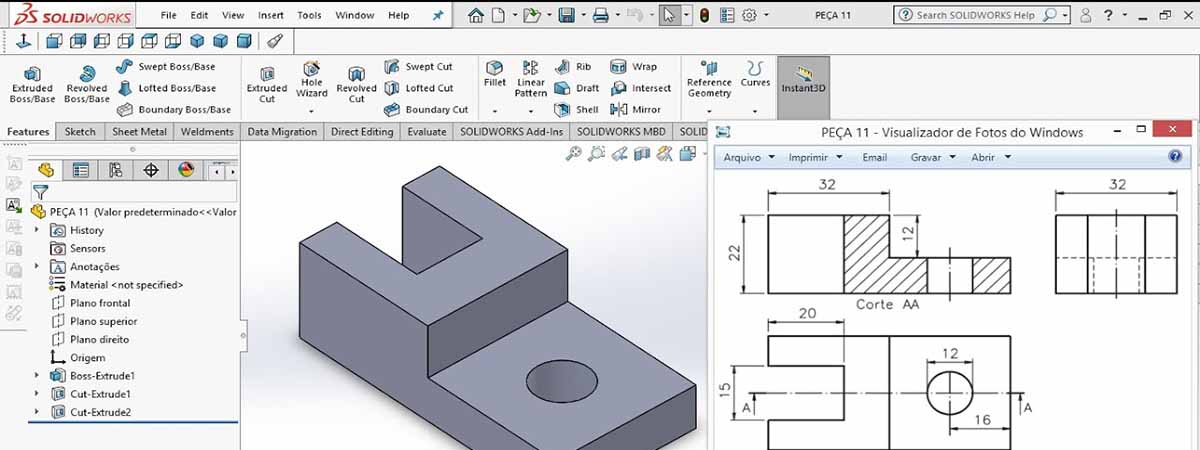

SolidWorks machining simulation

Image Description: The interface presents a 3D model prepared for manufacturing with highlighted toolpaths representing milling or drilling operations.

SolidWorks stands as a leading Commercial CAD solution. It finds its primary application in mechanical engineering and product design activities. Users can generate precise models and assemblies through SolidWorks because of its parametric design feature. Besides, the program presents multiple simulation capabilities, allowing users to conduct real-world analysis and evaluate motion performance. More to it, users can use the software’s compatibility with most CAM software platforms to transform their designs effortlessly into CNC programs.

Applications:

- Mechanical part and assembly design.

- The software platform enables user simulations for dynamic motion topics, material stress evaluation, and design flow analysis.

- 3D rendering for visual product development.

CAM (Computer-Aided Manufacturing) Software

This software is necessary for CNC machining as it converts CAD models into readable instructions. Such instructions are in the form of code. They help in perfecting tool paths and minimizing waste material.

Mastercam

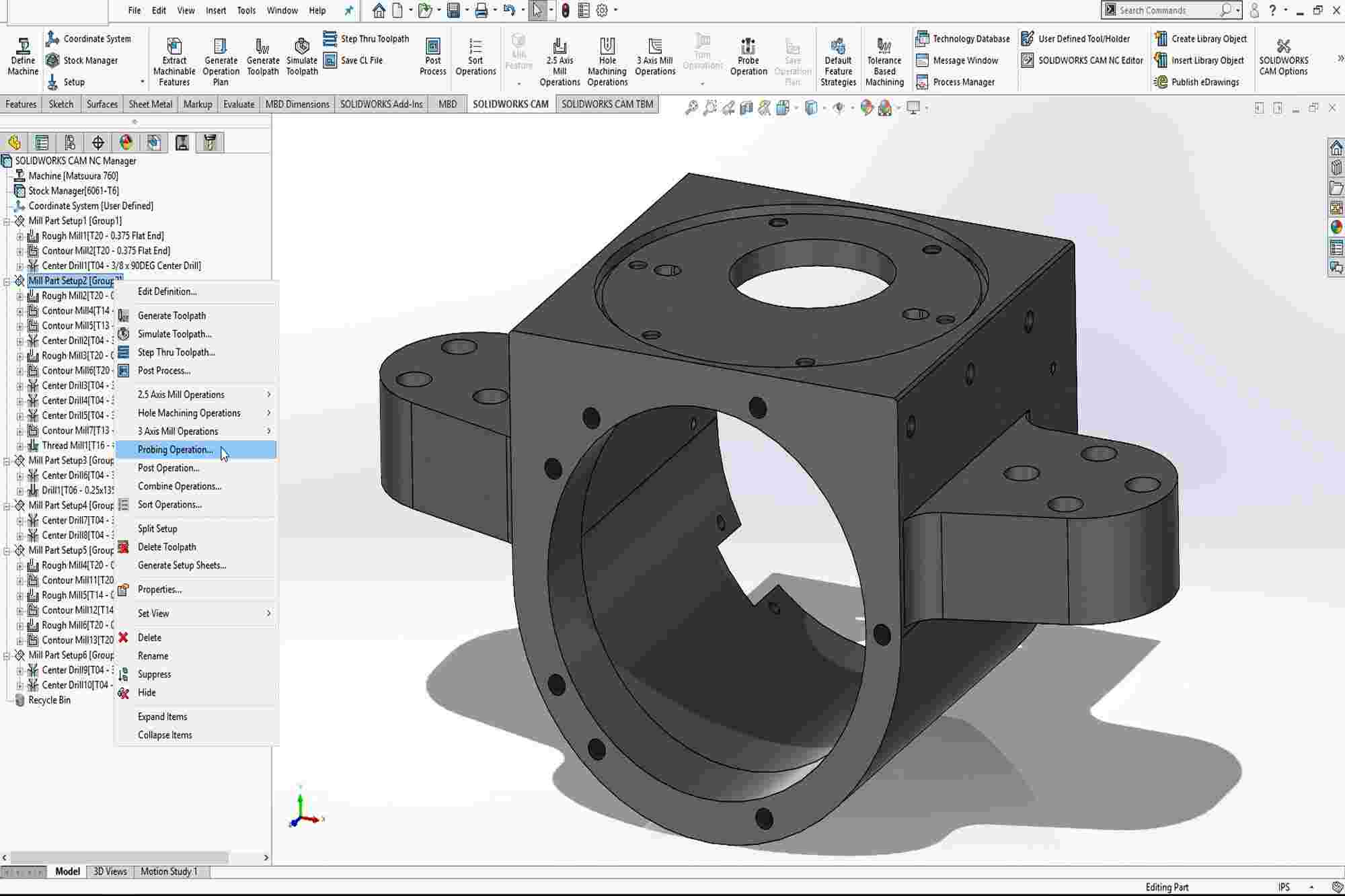

Mastercam toolpath

Image Description: A screenshot of Mastercam displaying a machined part with generated toolpaths. The CAM interface shows machining operations, tool definitions, and simulation controls.

Mastercam stands among the top CAM software applications because it provides extensive toolpath generation functionality. The software supports all types of machining operations, including 2D, 3D, and multiple-axis machining. Design Operators use these to attain their manufacturing needs from basic milling to complex multi-axis operations. Using Mastercam, users can optimize material removal rates and minimize tool wear because this software includes high-speed machining along with tool path optimization and dynamic motion technology. Moreover, you can precisely import CAD designs through the integrated software interface. It automatically generates tool paths during minimal setup operations.

Applications:

- Toolpaths made by the software enable CNC milling, CNC turning, and CNC multi-axis machining.

- The system optimizes manufacturing performance by producing rapid motion combined with dynamism during operations.

- It helps users decrease machine execution duration while minimizing discarded raw materials.

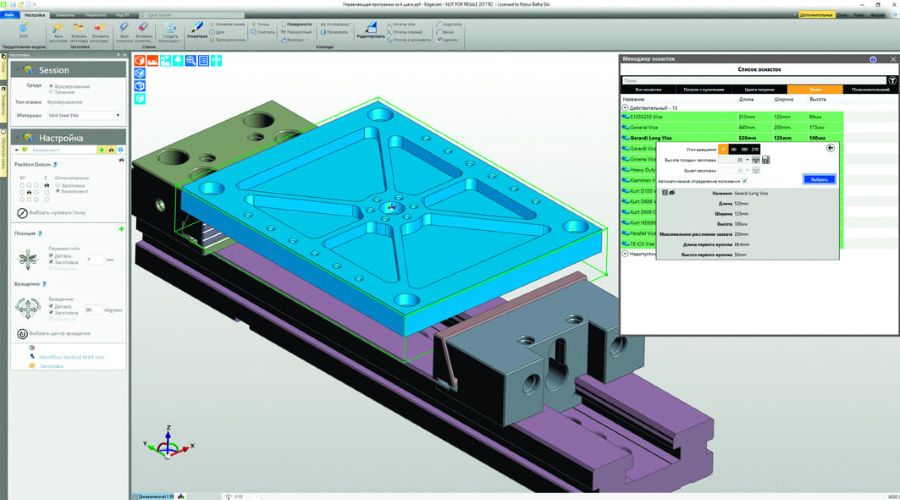

Edgecam

Edgecam CAM software

Image Description: A detailed view of Edgecam CAM software in use. The 3D component is displayed with colored toolpaths representing roughing, finishing, or drilling operations.

Edgecam serves as a flexible computer-aided manufacturing (CAM) software that delivers effective, highly intelligent machining technologies. The software platform enables milling alongside turning processes and EDM operations through its advanced simulation capabilities for tool path creation. Edgecam presents an interface that enables quick toolpath creation with precision and accuracy. Engineers use its automated features to maximize productivity when running repetitive workloads. In addition, the system comes with innovative strategy options, including multi-axis operations along with turning capability and high-speed processing capabilities.

Applications:

- Adaptive toolpath generation for various CNC operations.

- Multi-axis machining for complex parts.

- The use of automated toolpath generation techniques helps optimize workflow procedures.

CNC Control Software

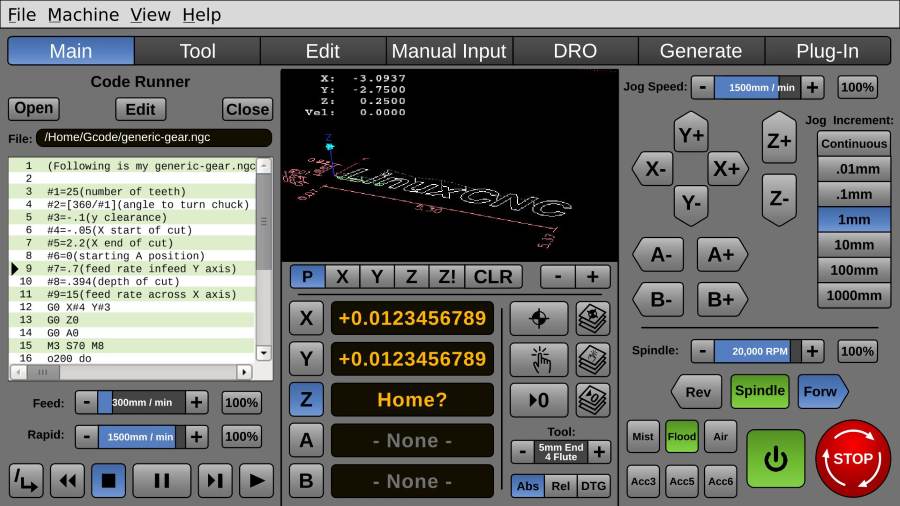

Mach3

Mach3 CNC

Image Description: A screenshot of the Mach3 CNC controller software showing G-code execution, DRO readouts, toolpath preview, and machine controls.

The CNC control software Mach3 serves as a leading choice for workshops and hobbyists in smaller operations. The software transforms G-code information into specific machine movements. Using these, you can control CNC routers together with CNC mills and CNC lathes. Operators take control of machines, along with getting real-time feedback to adjust machining operations.

Furthermore, the software package includes visual tools to view tool paths alongside customizable interface options and macro management for repeatable functions. Small-scale companies choose Mach3 because the tool offers excellent affordability and effective CNC control functionality, together with an intuitive interface and wide application abilities.

Applications:

- Real-time control of CNC machines like routers and mills.

- G-code interpretation and manual overrides for accuracy.

- Customizable interfaces and automation for small operations.

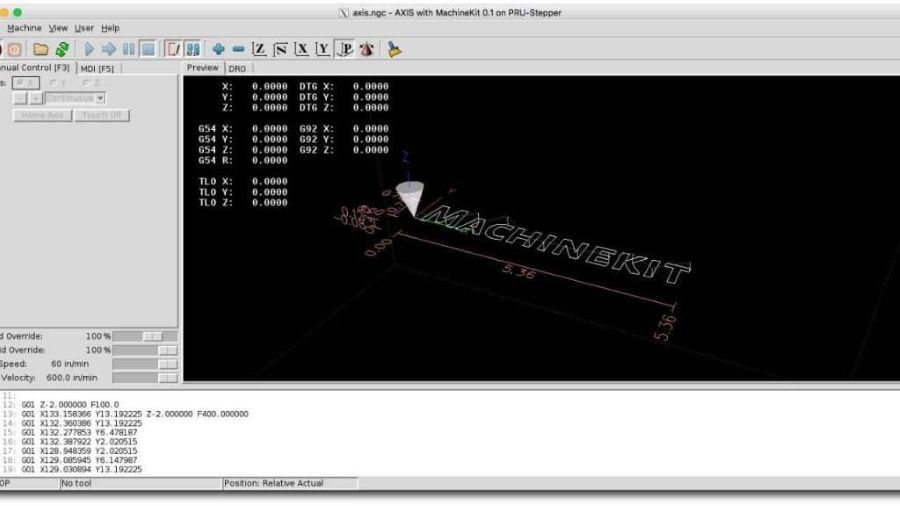

LinuxCNC

linuxcnc software

Image Description: LinuxCNC interface displaying machine coordinates and toolpath preview on a Linux desktop.

LinuxCNC functions as an open-source CNC control software that delivers high precision along with flexible capabilities. Linux systems host such applications that enable real-time control of milling machines, lathes, and routers. Through its multi-axis control capabilities combined with detailed customizability, engineers get an optimal solution for specialized and custom setups. The open-source framework allows users to alter the software according to their specific needs. Precision machining industries like aerospace, automotive, and electronics depend on LinuxCNC to handle their demanding operations.

Applications:

- High-precision CNC machine control for complex operations.

- Multi-axis motion control and real-time adjustments.

- Customizable software for specialized manufacturing needs.

CNC Simulation Software

Simulation software assists in visualizing the machining operation before actually performing it. Engineers use this to mitigate errors, perfect tool paths, and get precision. Major simulation tools include:

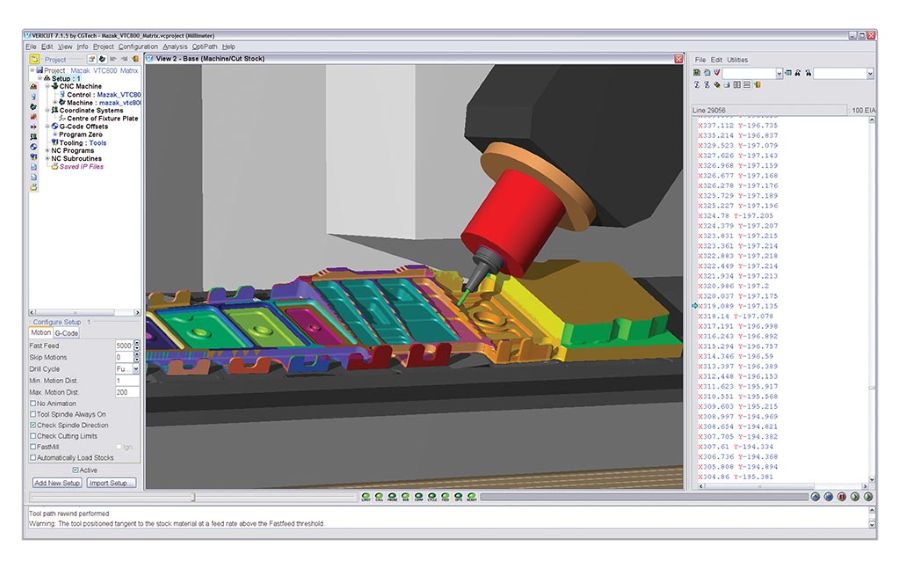

Vericut

Vericut CNC Simulation

Image Description: A screenshot of VERICUT displaying a 3D part with simulated CNC machining toolpaths.

The CNC simulation application Vericut helps users simulate CNC machining procedures. The program dictates toolpath verification to identify possible errors alongside pre-machining collision checks. Computers running Vericut software eliminate expensive production defects and reduce tool deterioration and unutilized materials throughout the whole job progression.

Moreover, the software offers integration with leading CAD and CAM systems. Using this, designers can perform simulations for both basic 3-axis and complex multi-axis machine operations. Vericut enables manufacturers to verify error-free optimized CNC programs before machine execution, which results in higher productivity alongside shorter production stoppages.

Applications:

- The system verifies CNC programs by searching for potential collisions.

- Toolpath optimization for efficient machining.

- The combination improves production efficiency by decreasing equipment breakdown time while delivering better part performance.

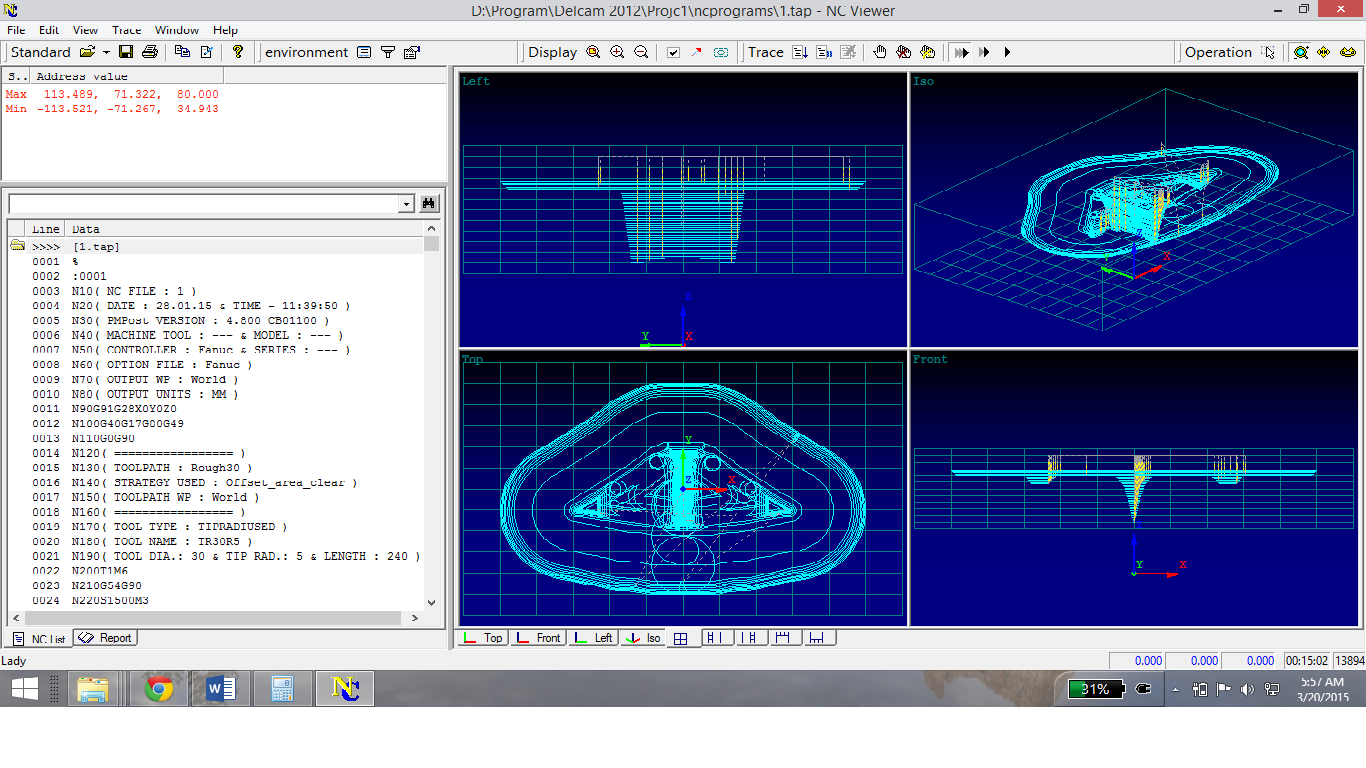

NC Viewer

NC Viewer

Image Description: NC Viewer interface showing a CNC toolpath simulation on a 3D part model.

Users can utilize NC Viewer as a free browser-based platform to visually preview CNC G-code and run program simulations for free. The software enables engineers to identify G-code errors before executing the program on manufacturing equipment. Multiple CNC machines can use NC Viewer for toolpath visualization, along with zooming and complete 3D simulation features. The basic yet practical NC Viewer platform serves as a preferred red tool for small shops and hobbyists due to its straightforward operation. Besides, as for its quick G-code review capacity.

Applications:

- G-code simulation and error detection.

- The software provides essential functionality for visualizing basic CNC programs while also enabling debugging routines.

- Machine operators, alongside engineer,s can use software checks for quick assessments.

CNC Nesting Software

CNC Nesting helps in efficiently arranging parts on the sheet to avoid any errors. In doing so, they improve productivity and reduce waste in fabrication and machining. Main ones include:

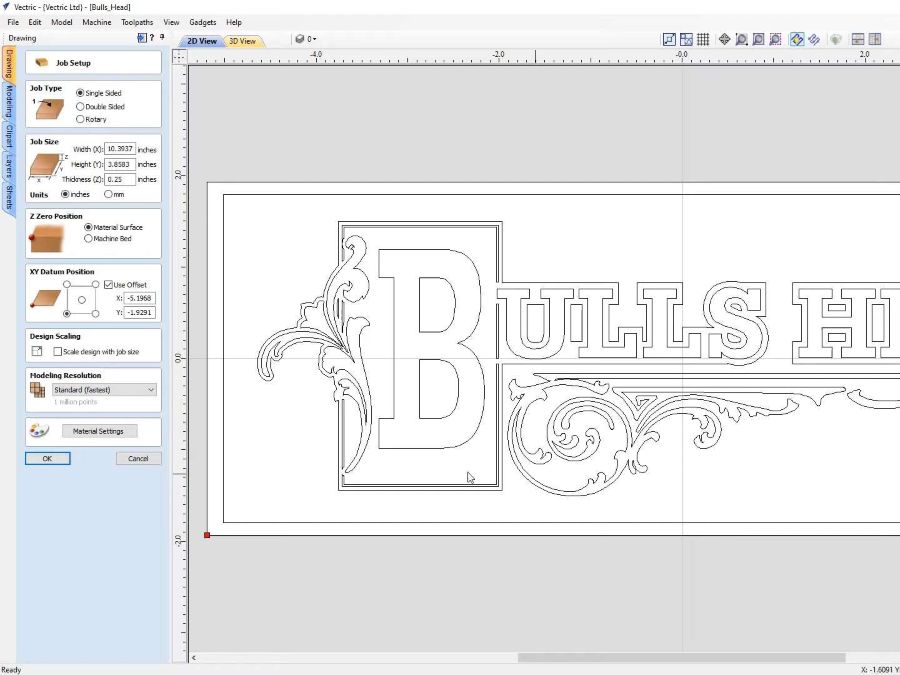

VCarve Pro

VCarve Pro CNC software

Image Description: A screenshot of VCarve Pro displaying a 3D part with generated toolpaths for CNC routing.

A computer numerical control (CNC) nesting program called VCarve Pro functions specifically for woodworking and sign/vectorial configurations in manufacturing operations. The software includes comprehensive capabilities that enable 2D and 3D routing along with engraving and cutting operations. Moreover, the software implements precise nesting algorithms. These maximize material efficiency while decreasing production costs.

In addition, VCarve Pro offers easy operation with advanced design handling capabilities that make it appropriate for businesses requiring precise routing in furniture designs and custom signage work. Small to medium woodworking businesses choose such software because its user-friendly interface supports complete toolpath creation to meet their production needs.

Applications:

- A CNC router enables users to create wooden products as well as signs through both routing and engraving operations.

- Material optimization and waste reduction.

- Custom furniture and signage production.

EnRoute

EnRoute CAD CAM

Image Description: A detailed view of EnRoute CNC software in operation. The 3D part is displayed with colored toolpaths representing milling or engraving operations.

Enroute serves as a leading efficiency booster for manufacturers. It helps produce wood alongside metal and plastic materials. Through its effective edge-cutting strategies, the software delivers smart nesting algorithms and toolpath optimizations for working with multiple materials simultaneously. Besides, its user-friendly interface encourages users to program complex jobs easily and efficiently. In addition, EnRoute provides outstanding performance during precision CNC operations, which generates minimal material loss while providing refined surface results. Industrial operations such as cabinet making, together with metalworking and sign fabrication, appreciate this software solution as it optimizes their production methodologies and improves their cutting processes.

Applications:

- Using precise cutting operations on metal in combination with wood and plastic materials.

- The intelligent system optimizes material usage through its nesting features.

- Custom cabinetry and sign production.

How to Choose the Best CNC software for your work?

Your manufacturing efficiency will experience a significant impact according to the CNC software selection you make. Your decision should incorporate the following elements.

Understand Your Machine Requirements

Software systems for CNC machines require precise specifications of their compatibility requirements. Specialized software becomes necessary for machines that need to perform CNC multi-axis machining or execute complex operations. Check that software systems function correctly with your manufacturing equipment features and functionalities.

Consider the Type of Materials

Each material type needs special fabrication techniques during the machining processes. Select software that supports operations for machining your particular materials such as metals, plastics, and composites. Software containing superior cutting functionalities presumes to be better material optimization and decreased material waste.

Look for Seamless Integration

The software must establish smooth connectivity between your installed CAD and CAM platforms. The smooth transmission of design information to machining operations leads to error reduction. Select software that operates correctly with your present workflow setup and existing machines.

Evaluate User-Friendliness

The ease of operating a system proves critical to productivity levels. Efficient software interfaces shortened employee learning times while decreasing operational mistakes. Software selection should include features that explain procedures fully and users should verify available video tutorials and technical support functions.

Cost vs. Benefits

It is imperative to examine the total expenses at the beginning and the advantages that will exist throughout an extended timeline. Look for software that offers reasonable prices while providing the necessary functionalities. The investment should lead to better operational efficiency, together with reduced equipment downtime in your machining operations.

Summary

In any manufacturing process, selecting the right software tool is key to getting the desired results. Software of different kinds excels in various applications and features. With the accurate selection of tools, you will be able to bring your imagination into the actual world. Detailed working and application of each software will help you in finalizing the best one for your application. Further, other product factors like feed rate, required precision, surface finish, cost factor, and input material must be taken into consideration. Overall, following all the above recommendations and comparing them with your machining requirements will help you choose your viable software tool.

Additionally, If you are looking for any more relevant information. We have professionals at Premium Parts who provide custom CNC programs and professional consultation. We will help you clear your operations so that your operations become more productive and more accurate than ever before.

FAQ’s

Q1: How can G-code impact the machining activity?

Geometric code defines the movement of machine tools, including feed rate, 3-axis movement, depth, and other specifications. Any error or inaccuracy in the code could result in waste material.

Q2: Is CNC software tough for beginners?

The CNC software comes with interactive interfaces coupled with learning guidelines to help beginners. This makes it much easier to learn such software.

Q3: Is there any free CNC Software?

Yes, multiple software contain their free version for basic working. Major ones include FreeCAD, Linux CNC, and GRBL.

Q4: Which Software should I choose?

Selecting software depends on the requirements of the workpiece, and the involved machining tasks. For example, MasterCAM is preferred for interface navigation, part setup, and plane creation. Besides, Fusion 360 is well-known for its engineering simulation and 3d design. SolidWorks is used for flow modeling.

Q5: What are the top 10 CNC software?

Main CNC software famous in machining works include:

- Mastercam

- SolidWorks CAM

- Fusion 360

- EdgeCAM

- CAMWorks

- Mach3

- GibbsCAM

- Powermill

- EnRoute

- LinuxCNC