We are all aware that metal surfaces are prone to deterioration due to various factors, including coating limitations and environmental issues. Thus, you need a technique that not only enhances the appearance of products but also their durability. This is where chrome plating comes in as a perfect solution. Besides, if you are in the manufacturing industry, you can’t be unaware of chrome plating and its advantages. Chrome plating is a technique that prevents the parts from corroding, wearing out, and losing their shine. It involves depositing a layer of chromium on the parts to provide a protective and shiny finish.

In this modern era, people seek reliability and durability, along with a subtle shine and aesthetic appeal. Therefore, whether it’s aerospace, automotive, or another industry, accuracy and aesthetic appeal are crucial. However, to obtain precise results, it is essential to understand the process, types, and applications. Let’s explore how this method enhances the appearance and properties of parts.

What is Chrome Plating?

Chrome Plating

Image Description: The image shows a metal component with chrome plating applied to its surface. The shiny, reflective chrome finish highlights the smooth texture and polished look.

Before talking about chrome plating, let’s first consider electroplating. It’s a process that adds a layer over another metal and serves as a shield against rust. Generally, we use a corrosion-resistant layer for the metal, which is prone to rusting. This helps protect the metal and increases its durability. Now, let’s get back to the main topic: What is chrome plating, after all? Well, in chrome plating, you electroplate a thin layer of chromium over a metal object. We also call this plating chromium plating.

With chrome, the end product appears shiny, corrosion-resistant, and more durable. You can use many other products to enhance the surface finishes, such as aluminum polishing. However, chrome plating offers a better, high-quality finish with accurate reflections.

History of Chrome Plating

Chromium has been in use since the 20th century. That was when chromium became known for its protective properties. However, its use in the manufacturing industry to electroplate metals started in 1920. Therefore, the manufacturers could create the parts which were not only visually appealing but also had a good build to defend against rust and other environmental factors.

With time, plating has undergone many alterations. You can say it evolved and turns out in many methods and forms according to industrial needs. Its major advantages are the reason why chrome plating remains stable for aesthetic finishes.

Factors to Consider While Doing Chrome Plating

Before starting with the chrome plating, it’s best to take the necessary precautions for safe and quality results. Therefore, you should ensure the part is clean and does not have any dust or dirt fragments that can affect the quality and strength. Mostly, there are surface impurities such as oil and grease, which need to be cleaned up with chemicals and other methods. The cleaning will ensure a better finish with uniform plating.

Moreover, the activation bath generally includes acid to ensure a balance in its temperature. With the use of chemicals like sulfuric acid, you can get more awesome results, but with optimum use. Here are some other factors you need to consider:

- Bath Temperature: Make sure to keep the temperature of the bath liquid under control. Besides, the metals have different temperature capacities from each other, so it can impact their quality of finish.

- Current Density: Keep the current density under control, as it influences the chromium accumulation on the surface of the metal. It helps in achieving uniform thickness and guarantees better adhesion.

- Plating Time: Time also affects the thickness and quality of the chromium finish. Therefore, the more time it takes, the thicker the coatings will be, which will enhance the durability and resistance against wear and tear.

The Procedure for Chrome Plating

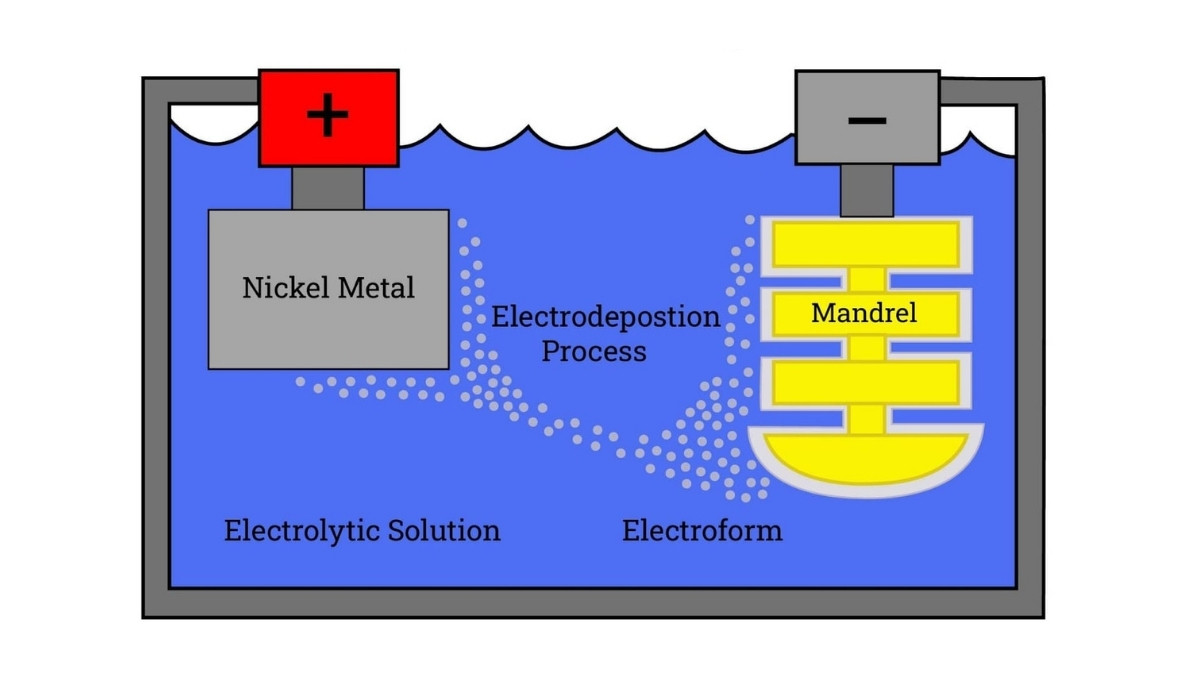

Chrome Platng Process

Image Description: The illustration presents an overview of the chrome plating process. It highlights key components like the anode, cathode, mandrel, and the electroposition phase. The metal object is shown connected as the cathode, while the anode releases chrome ions in the solution..

The process of chrome plating includes electroplating, which involves chromium coating over metal. Therefore, an electrical charge is needed for electroplating. A container containing chromium anhydride is subjected to an electric charge. Consequently, the chromium metal undergoes deposition over the other metal surface with this charge. Here’s the step-by-step process you need to consider:

1. Prepare the Surface

The first and crucial step of chrome coating is cleansing the part on which we are going to put a chromium layer. Usually, after manufacturing, the products have dust, oils, and scrapes. It’s best to clean them using chemicals. The chromium layer sticks better and uniformly on a cleaned surface.

2. Activation Bath

After cleansing, we prepare an activation bath, which usually contains dilute acid. We submerge the metal part in it, which reacts with the acid to make its surface a little rough. This step prepares the metal for plating and ensures the chromium bonds with it efficiently.

3. Base Layer Application

Whether you are going for decorative or hard chrome, a base layer of nickel is necessary. Thus, before applying chromium, we use nickel electroplating over the metal. This makes the metal’s surface smoother and more corrosion-resistant. Shortly, it enhances the quality and results in a better chromium finish over the metal.

4. Chromium Plating

With the nickel plating over it, the metal part is now ready for chromium treatment. We dip the part in a bath of chromium and other acids. An electric current passes through the solution, causing chromium ions to bond. These ions react with the metal surface and form a layer of chrome over it.

5. Rinsing and Drying

After the plating, we thoroughly cleaned the item to remove any residual acids and chemicals. Then, we let it dry and polish it for a better finish.

6. Quality Check

Finally, after the drying process, we scrutinize the part. We check for defects, impurities, cracks, and uneven surfaces. If they are still there, we repeat the process to get good results.

Types of Chrome Plating

Chrome coating exists in multiple forms that include the following types.

Decorative Chrome Plating

Decorative Chrome Plating

Image Description: A close-up view of a metal part with decorative chrome plating. The surface is highly polished, with a smooth, mirror-like finish.

Decorative chrome plating is a process that involves beautifying surfaces. Plating a surface with chrome creates a thin layer for aesthetic purposes. It provides a bright, reflective finish, ideal for applications where aesthetics matter.

After surface preparation, which means cleaning and an activation bath to remove impurities, the process starts. It is essential to ensure that the surface is clean, smooth, and free from contaminants.

People use household fixtures and kitchen utensils with decorative chrome layers. It has a sleek, shiny appearance that is common on car trim, bumpers, and motorcycle parts.

Hard Chrome Plating (Industrial Chrome)

Hard Chrome Plating

Image Description: The image shows a metal component with a thick layer of hard chrome plating. The surface appears durable and wear-resistant, with a matte and slightly glossy finish.

Industrial chrome plating provides functionality rather than appearance. It uses a thicker layer of chrome to offer wear resistance, surface hardness, and corrosion protection.

The first process of the surface treatment is cleaning and surface preparation, which is similar to decorative plating. Yet the primary goal is to guarantee an easy-to-develop base that can accommodate a thicker chrome layer.

Hard chrome plating is commonly used for heavy-duty machine components, cylinders, and industrial tools due to its durability and cost-effectiveness.

Thin, Dense Chrome Plating

Thin, Dense Chrome Plating

Image Description: The image showcases a metal part coated with thin, dense chrome plating.

The process applies a dense, thin plating of chrome onto metal parts to create a smooth, dense coating. In contrast to conventional hard chrome, this technique applies a thinner layer of chrome, usually with the use of a specialist chromium bath. At a slightly lower temperature, the process allows for a denser coating that, in turn, improves wear resistance and decreases friction. Dense chrome at an ultra-thin layer acts as corrosion protection for components located in harsh conditions.

Users from the fields of hydraulic cylinders and aerospace manufacturing, as well as industrial machinery, apply this process for products that need tight tolerance levels. One major advantage of this method is that it is capable of reducing surface friction while achieving a very high level of hardness.

Black Chrome Plating

Black Chrome Plating

Image Description: A close-up view of a metal part with black chrome plating. The surface has a dark, almost matte finish, offering a sleek and sophisticated look.

The black chrome layer gives parts a smooth, dark, and exclusive look. The bath receives a specialized chemical treatment to produce dark, glossy coatings.

Applications are common in automotive parts, optical equipment, and decorative fixtures. It is ideal for applications that desire a sleek, modern look or black chrome.

Micro-Cracked Chrome Plating

Micro-Cracked Chrome Plating

Image Description: The image displays multiple metal parts, each with a layer of micro-cracked chrome plating.

Micro-cracked chrome plating comprises a standard hard chrome process in which the layer deposited shows fine cracks on the surface. Controlling the bath composition, temperature, and current density accomplishes plating. As the chrome layer cools, these cracks form naturally through a network of microcracks.

Engineers prevent a single large crack from forming under stress by utilizing microcracks. Such chrome is very suitable for applications where high wear resistance is a must, for example, hydraulic cylinders and piston rods.

Flash Chrome Plating

Flash Chrome Plating

Image Description: The image depicts several metal parts undergoing flash chrome plating, with the parts securely held in place by jigs.

Chrome coating applies a thin layer of chrome to a substrate, achieving a thickness of as little as 0.00004 inches (0.0001 mm). This method is quicker than traditional chrome plating and is used for decorative purposes.

Applications involving a shiny, smooth finish that is not too thick are where flash chrome is ideal. Automotive parts, along with kitchen utensils and consumer goods, frequently demonstrate this plating technique.

Satin Chrome Plating

Satin Chrome Plating

Image Description: The close-up image displays a metal part with satin chrome plating. The surface exhibits a smooth, matte finish with a soft sheen.

Satin chrome differs in that it offers a matte, non-shiny, and polished appearance compared to shiny chrome. Brush the surface of a base metal, then deposit a thin layer of chromium over it. This method normally utilizes a standard chromium bath, but the final step involves making the smooth, satin surface.

A satin chrome coating can be applied to car parts, door handles, and kitchen utensils to achieve a subtle, elegant appearance. It offers reasonable corrosion resistance and surface hardness, making it typically ideal for situations where appearance and function are equally important and necessitate a coating.

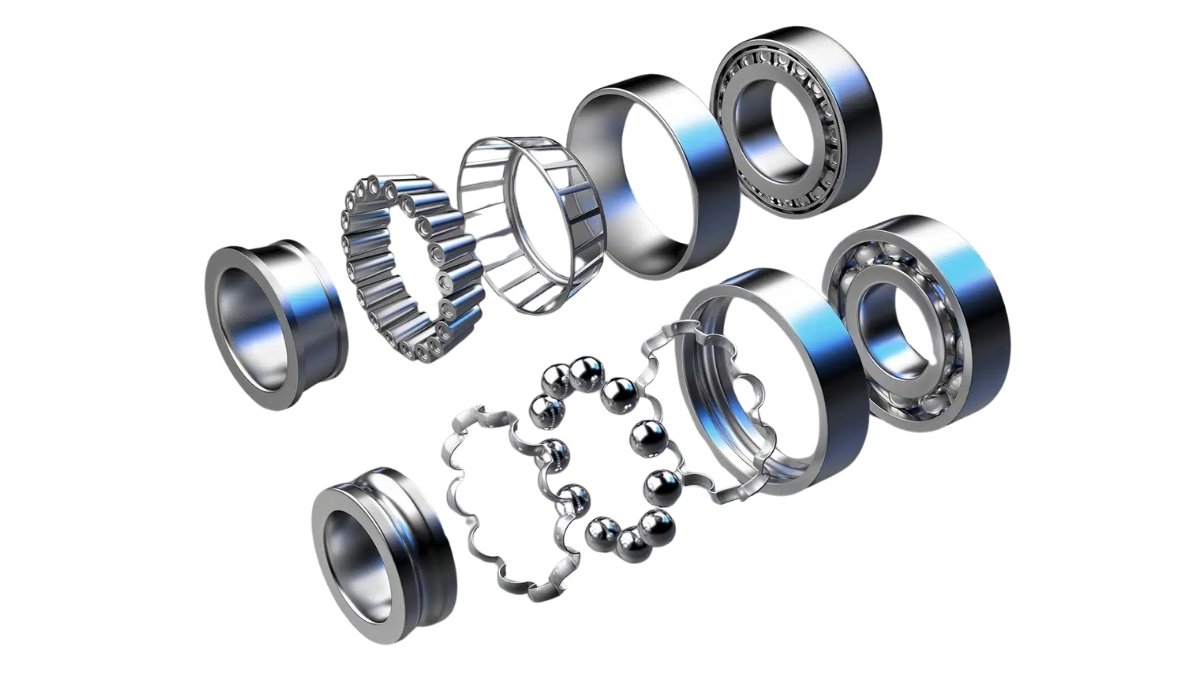

Micro-Porous Chrome Plating

Microcracked chrome differs from micro-porous chrome, focusing on creating tiny pores rather than surface cracks. Adding certain additives to the chromium bath induces the formation of micro-pores in the chrome layer.

Lubrication microspores improve friction reduction and extend the life of engine bearings and gear shafts.

Roll Plating Chrome

Roll Plating Chrome

Image Description: The image shows a large metal part undergoing roll chrome plating. The part is mounted horizontally and supported by rollers for smooth rotation.

Cylindrical tools, such as rollers and printing cylinders, undergo electrolytic coating with chrome through a roll plating process. A rotating mechanism rolls a part through a chromium bath to achieve an even chrome layer.

Due to the high durability of the chrome layer, roll plating is ideal for parts that experience high wear, such as those used in printing or industrial machinery. It is harder, resistant to corrosion, and available in a polished finish.

Chrome Plating vs. Zinc Plating Vs. Nickel Plating

The electroplating process works with multiple varieties of metals. The three most common metals utilized for electroplating applications are nickel, chrome, and zinc, with their selection based on industry standards and component utilization areas. This article examines the distinctions between nickel, chrome, and zinc plating.

Chrome Plating

Chrome resists acids, alkalis, and humid environments, maintaining stability in harsh conditions. Besides, this metal possesses strong heat tolerance coupled with excellent mechanical wear capability and adequate hardness.

Zinc Plating

The Zinc plating performs well regarding corrosion resistance while showing a lack of protection against alkalis, sulfides, and acids. Zinc exhibits strong mechanical characteristics. Moreover, it serves well in hot and humid areas because it maintains stability as a metal.

Nickel Plating

The hard substance of nickel plating provides effective resistance against corrosion. Nickel plating is often applied over a copper base to improve corrosion resistance. Due to its reflective properties, nickel serves as an attractive decorative material.

What Are the Benefits of Chrome Plating?

Longer Lifespan: It extends the lifespan of metal surfaces by protecting them from corrosion and wear.

Aesthetic Appearance: Gives a sleek, business-like appearance by adding a polished, reflecting surface.

Increased Strength: Strengthening surfaces increases their resistance to impacts and scratches. Reduced friction minimizes wear on moving parts, improving efficiency.

Heat Resistance: Industrial applications use materials with high heat resistance.

Ease of Cleaning: Repels dirt and other nasties that cling to heavily textured surfaces.

Applications of Chrome Plating

Chrome Plating finds extensive use in industries because it improves surface characteristics, including hardness, corrosion resilience, and visual appeal. The main application sectors for this technique appear in the following list.

Automotive Industry

Automotive companies use chrome plating on vehicle components like trims, grilles, bumpers, and exhausts for both functional and decorative purposes.

Industrial Equipment

In the industrial sector, hard chrome plating of machine components such as cylinders, pistons, and hydraulic rods provides wear resistance and a longer service life.

Aerospace

The aerospace industry needs heat-resistant components combined with high strength and light weight. Manufacturers apply chrome plating to steel and aluminum to improve their durability.

Chrome plating serves aircraft components by protecting them from three elements: friction, corrosion, and stress. Engine parts, alongside landing gear and hydraulic systems, receive chrome plating from manufacturers.

Consumer Goods

Decorative chrome plating enhances both the appearance and longevity of faucets, handles, utensils, and kitchen fixtures.

Medical Devices

Chrome plating protects medical components and surgical tools. It helps improve the durability and sterilization of these components. The chrome-plated tools are highly corrosion-resistant and can withstand chemical use and sterilization.

Environmental Risks Associated with Chrome Plating

The environmental and health risks associated with chrome plating, especially hexavalent chromium, are significant. Hexavalent chromium (Cr(VI)) is a known carcinogen, posing health risks through inhalation, skin contact, or groundwater contamination.

Chromium plating operations can release hexavalent chromium as fumes and mist, causing respiratory and skin problems, as well as long-term health issues.

To mitigate risks, chrome plating facilities implement fume suppressants and ventilation systems to minimize harmful emissions. They also require regular monitoring and the use of personal protective equipment (PPE) to protect workers’ health.

Conclusion

What your project needs dictates which metal finishing technique you choose. Chrome plating remains a top choice due to its corrosion resistance, durability, and polished appearance. It’s a top choice for both rugged industrial applications and stunning consumer products.

The versatile properties of chrome make it possible to use it both on machine components and decorative pieces. However, when there are specific needs, such as a need for uniform coating, color variety, or matte finish, they may be better suited to powder coating, anodizing, or nickel plating. By knowing the strengths of each method, you can easily make a decision that will provide you with the best results, balancing performance, design, and/or budget.

Start Your Chrome Plating Project with Premium Parts

Are you starting a new project requiring chrome plating on the components? Premium Parts stands ready to serve customers through their high-quality secondary finishing processes, with chrome plating as an option.

So, give us a chance to enhance the properties of your components by adding a chrome layer to them.