What are the holes in engineering and manufacturing? Generally, a hole is a pit or opening made by drilling or boring into a workpiece. These holes come in different sizes, shapes, and uses. Moreover, their depth and orientation determine the functionality and performance of the final part. The significant uses of holes include joining assembly, reducing weight, positioning different parts correctly, ensuring fluid flow, etc. Besides, there are various types of holes in engineering, and each comes with other functionality.

From through, bling, and counterbore, each hole has a specific purpose for mechanical systems. Thus, understanding the holes, their design, features, and usage is necessary to use the right one for the proper purpose. Let’s explore the different types of holes and what makes them unique. Understand the types and choose the best hole for your project.

Overview of Holes in Engineering

Holes in Engineering

Holes in Engineering

Image Description: A close-up photo shows a machined metal part with clean circular holes. An Engineer measuring dimensions using calipers highlights the hole sizes on the actual metal surface.

The simple definition of a hole in engineering refers to a 3D opening or cavity extending into the workpiece’s surface. Many projects in our surroundings often contain flaws or defects. Some are covered with nuts or screws; the most common examples are door handles, automobiles, and industrial machinery. In short, most of the machinery around us is incomplete without these holes.

Moreover, the most common speculation is that holes are circular, but it’s wrong. In engineering and manufacturing, these holes are in different shapes, from squares, ovals, tapered, and others, according to needs. These shapes result from specific machinery and procedures, including boring, tapping, drilling, etc.

Some Major Features of Holes

What part or product are we going to make? What will be its dimensions and applications? All of these queries help you decide to create a specific hole and its features. Usually, we call it a circular pit that can pass through the surface or close to the other end. We use multiple symbols to describe different holes, such as’ Ø’ for simple engineering holes. In addition, CNC and EDM drilling techniques are used to create holes. Typically, a hole will include the following features:

- Location

- Diameter

- Tolerance

- Depth

- Shape and size

- Datum and references

- Chamfer on the edges

- Chamfer on the bottom of the hole

Types of Holes in Engineering

There are many types of holes in engineering, depending on their functionality and structures. Additionally, every hole type fulfills specific requirements and comes in handy uniquely. Here are some significant kinds of holes:

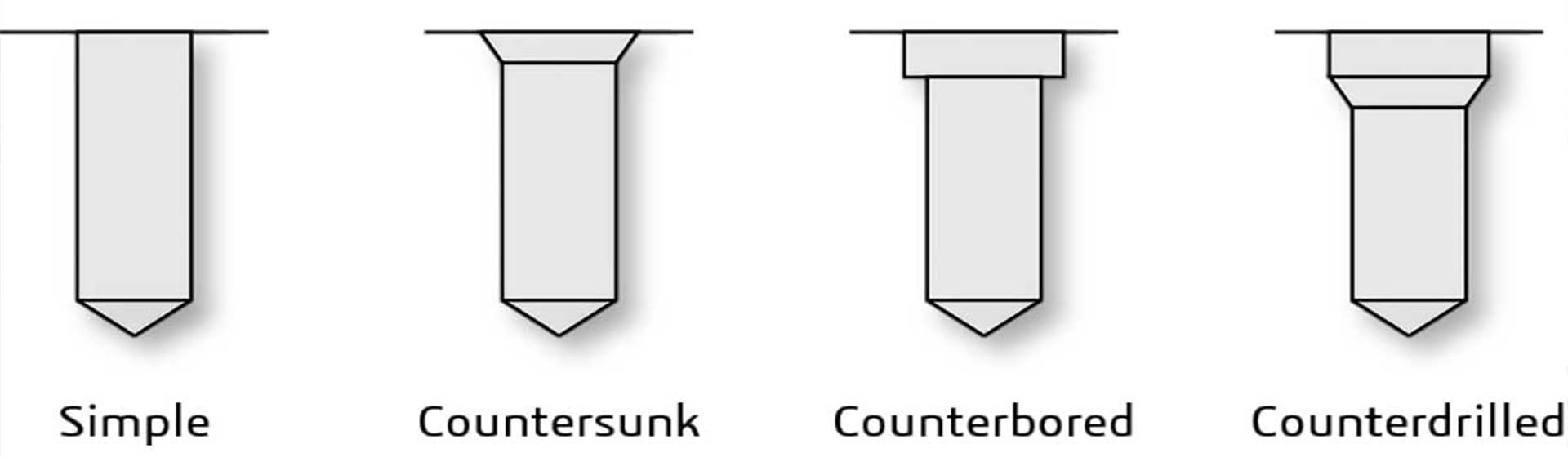

1. Simple Holes

Simple Hole

Image Description: An illustrated metal plate shows a single round hole with dimension lines marking its diameter.

A simple circular hole with a uniform diameter. The hole has a cylindrical bore with an equal diameter till the end. It extends through the material with a circular shape. The most common use of circular holes is to assemble different parts and provide clearance. Their symbol is Ø.

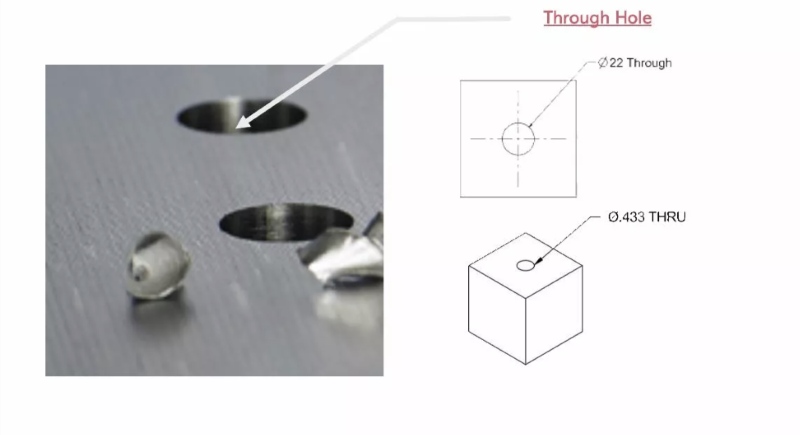

2. Through Holes

Through Hole

Image Description: An illustrated part shows a hole with dimension lines indicating its diameter and depth.

A through hole is also one of the most used types of holes in engineering. Generally, it passes through the material and is open on both sides. In simple words, you see the other side through one end. One primary use of this hole is to fasten different parts and allow the fluids to pass through the joints without leaking. Besides, they are also used for wiring because of their greater flexibility and safe use. Their symbol is “Thru,” usually written with a diameter (Ø) such as Ø25Thru.

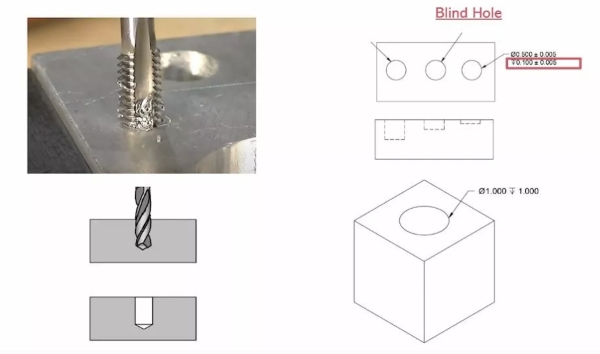

3. Blind Holes

Blind Hole

Image Description: An illustration shows a hole that does not go all the way through the material. A drill bit is positioned above the hole, and dimension lines indicate its depth and diameter.

A blind hole is like a glass with a bottom, meaning it does not extern through the material. In other words, it’s just a cavity with a closed bottom. One can place screws, fasteners, and other parts in them to use them. Their functionality includes tightening the objects to make projects such as metal works successful. Moreover, the significant advantage is that the screws inside these holes are less visible. Blind holes serve the best when it comes to precision and better appearance. Their symbol is “↓,” written with the diameter Ø, e.g., Ø 25↓10mm.

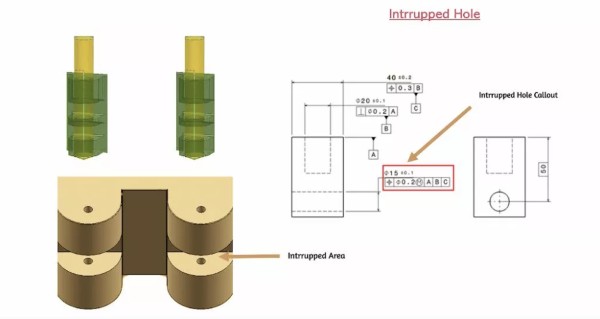

4. Interrupted Holes

Interrupted Hole

Image Description: An illustration shows a hole partially cut into a material with gaps along its edge. Dimension lines highlight the width, depth, and interrupted sections of the hole.

Interrupted holes come circular, but their shape is inconsistent from start to end. They include interruptions in their depth. The drilling process includes sequences of coaxial holes with gaps in the material to make this hole. Similarly, they come with cutting and non-cutting cycles. However, the hole remains on the same axis. Bearing seats and bolts hiding inside the holes are their standard functionalities.

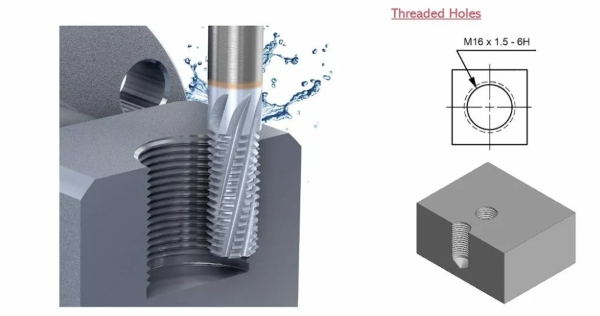

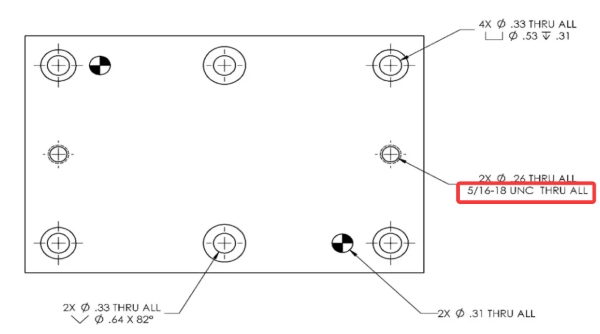

5. Threaded Holes

Threaded Holes

Image Description: An illustration shows holes with internal threads.

One of the unique types of holes in engineering is its design, which comes with the threads. They seem like tapped holes. However, their functionality and build are different. In big mechanical machines, threaded holes are an integral feature that fastens their parts. Manufacturing these holes is not complex; you only need a CNC machine. Their diameter symbol is ‘Ø,’ and in the metric system, it changes to ‘M.’

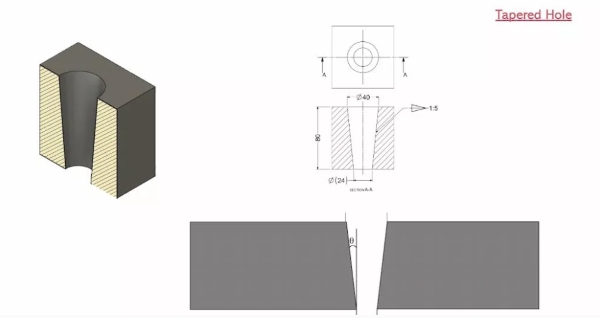

6. Tapered Holes

Tapered Hole

Image Description: An illustration shows a hole that narrows gradually from the top to the bottom.

In tapered holes, the diameter does not remain the same from one end to another. It reduces gradually through the whole length of the hole. Make the joints fit by pressing, e.g., connecting two parts by applying pressure. Moreover, they also have applications in fluid control systems and seals. These holes have measurements and degrees, meaning how inclined the hole is from start to finish.

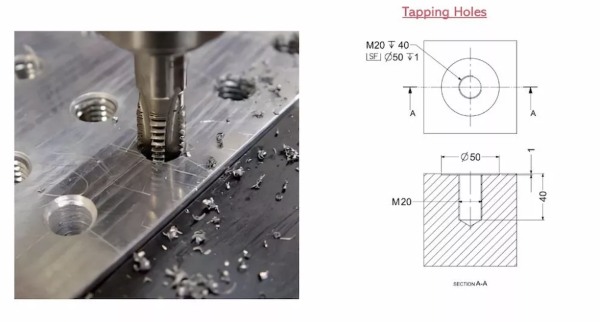

7. Tapped Holes

Tapped Hole

Image Description: An illustration shows a hole with internal threads created for a screw. Dimension lines indicate the hole diameter, thread pitch, and depth.

All the types of holes in engineering, tapped and threaded holes, confuse people. The reason is that the tapped hole also comes with cutting threads. However, what makes them different from the other is the technique and machinery used to create them. A highly proficient Tap machine can create these holes by cutting the threads into the material. Subsequently, these holes can fasten the objects with the help of screws and bolts. The taps include different sizes and dimensions depending on the requirements. Their sign is “M.”

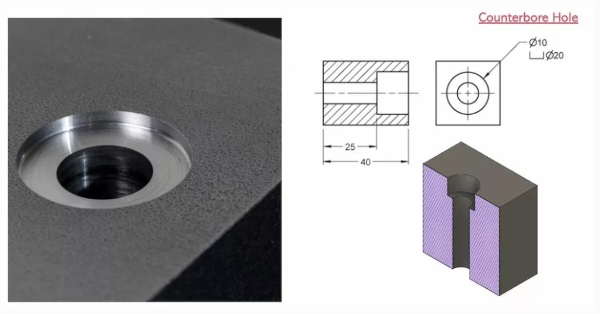

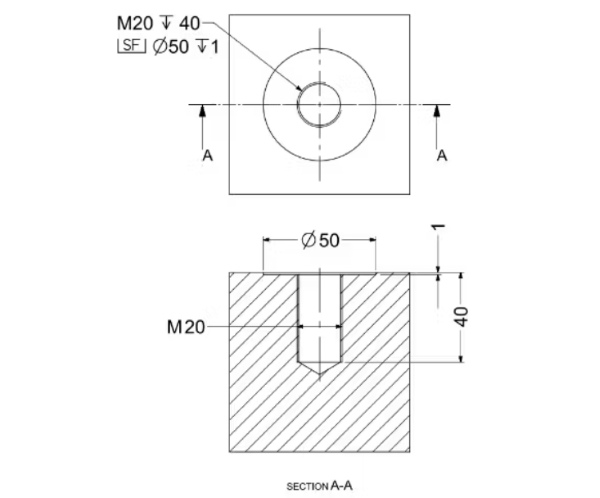

8. Counterbore Holes

Counterbore Hole

Image Description: An illustration shows a hole with a larger flat-bottomed section at the top.

A Counterbore hole is generally a deeper hole than an existing one. For example, there is an existing hole on a shallow surface. Now, take a drilling machine and dig deeper into that hole; however, the new hole has a smaller diameter than the first one. Consequently, you have two holes now: a deeper hole and another shallow hole. The hole with a larger diameter, which has low depth, can let screws and bolts reside on its surface.

This helps to make the above surface smooth without sticking out on the surface. Their significant uses are in metal and woodwork, which require precision and a better appearance. Their symbol is”⌴”with the diameter symbol Ø and numeric value such as ⌴ Ø80.

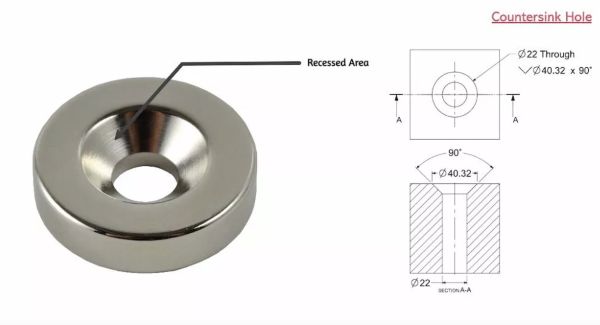

9. Countersink Holes

Countersink Hole

Image Description: An illustration shows a hole with a conical top to fit a screw head.

Counter sinks are just like circular sinks with the shape of a cone. These bolts also hide the heads of screws and bolts to ensure smoothness of the above surface. Countersink bolts have major applications with a risk of bumps, injury, and damage. They have different sizes and shapes depending on the material requirement. You can use these holes with wood, metal, and even plastic. Their symbol is”⌵”.

10. Counterdrill Holes

Counterdrill Holes

Image Description: An illustration shows holes with a drilled recess at the top.

Counterdrill holes are one of the most sought-after types of holes in engineering. They also ensure the above surface is smooth by fitting the recessed head at level as the material’s surface. This results in a good appearance and ensures the fastening is done right. Counterdrill holes offer safety and quality and have diverse applications in industries requiring precision and strong fastenings. Their symbol is the same as countersinks.

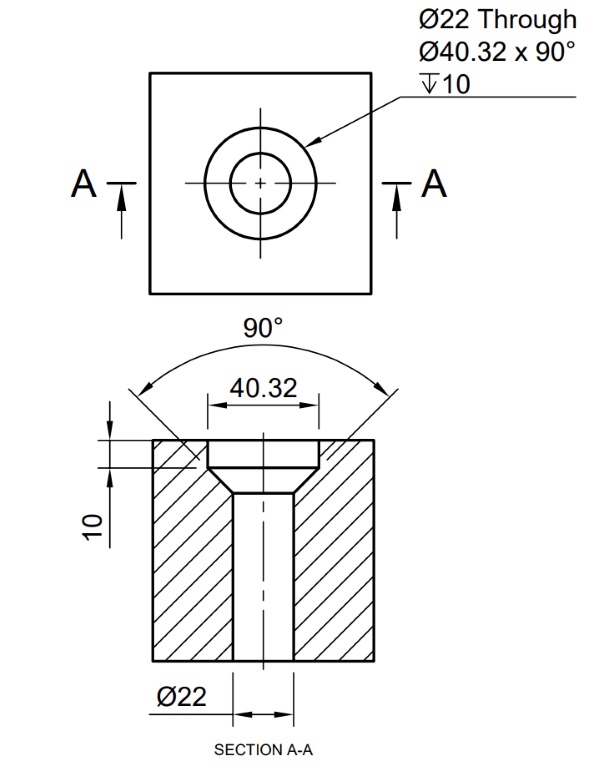

11. Spotface Holes

Spotface Hole Illustration

Image Description: An illustration shows a hole with a shallow, flat surface around the top.

Spotface holes extend to the bottom of the material in regular size and fit within the surface. They provide a flat surface by merging with and not showing up above it. This offers uniform pressure distribution, resulting in secure and smooth fastening. Moreover, their primary functionality is sealing and fastening materials. Their symbol is usually ⌴ an SF above it in engineering.

12. Screw Clearance

Screw Clearance

Screw Clearance

Image Description: An illustration shows a hole slightly larger than a screw to allow easy insertion.

A screw clearance hole has a big diameter to let the screws pass through it. However, the oversized bolt or head of the screw resides on their surface to tighten them. Their call-out symbol is the same as a simple hole. However, the depths and design structures differ from them. Besides, their sizes are also different as their diameter adds up to the diameter of the screw head and bolt as well. CNC milling machines can create these holes accurately.

13. Reamed Holes and Overlapping Holes

Reamed Hole Illustration

Image Description: An illustration shows a smooth, precise hole created by a reaming tool. Dimension lines indicate the final diameter and depth of the hole.

Reamed holes are not popular for special types of holes in engineering. However, they have their importance in accuracy and premium quality. You create them; we need the right size of the reamer and CNC drilling machine. Another less talked about type of hole is overlapping holes. It includes the collision or match of two different holes. Their primary applications are in metal manufacturing industries and complex buildings.

Considerations to Choose the Right Hole Type

The correct hole type is essential to complete your machining and fabrication projects. Therefore, you need to look into the materials’ specs, requirements, and applications. A single hole can determine the structural fitness and alignment of the products. Any incompatibility with the hole can lead to failure and malfunction of the products. Thus, look into the following considerations to choose the right hole type:

- Consider the purpose: Know the goals clearly and what you want to achieve. So, first consider the purpose of making a hole, whether for assembling, fabrication, or joining. Next is to evaluate the material, which will give you insights into choosing the right size and shape of the hole.

- Size and dimensions: Consider the depth of the hole and its size, e.g., diameter, to get the task done. Some major dimensions of holes are circular, square, and rectangular.

- Type of Material: The material you will use to make holes also matters. Their type will determine what kind of machinery to use in making holes.

- Hole Depth: Determine the hole length; you must choose the correct length for the drill bit or saw.

- Power Source: What kind of machinery will you use for this job? Choose the right power source; for example, drilling in hard material requires more power than a feeble surface.

Final Verdict

Holes play a significant role in offering security, stability, and good performance for many products. The wrong choice of holes and machinery to create them can result in the malfunctioning and running of the final product. Thus, doing proper research and keeping balance while drilling or milling is essential. At Premium Parts, we know the importance of holes and their functionality. Our high-end machines and expertise result in precise holes according to the requirements.

We have CNC milling, tapping, EDM drilling, and CNC drilling machines. We help you turn your raw idea into a masterpiece. Our commitment to excellence allows us to manufacture precise and premium products. Get our expert services to have excellent results.