Let’s be honest, if you’re developing a product, pricing matters. And not just in the “let’s stick to the budget” kind of way. I mean it really matters.

Because if you’re choosing the wrong manufacturing partner—or paying bloated machining fees—you’re not just burning money. Also, you’re delaying launches, killing margins, and putting your product quality at risk. But don’t fret, CNC machining is the solution to eliminate all these potential risks. However, you need to understand where your money is going.

Especially when every hour of machine time could mean the difference between making your project fly, or flop. So, what’s the deal? What’s the real hourly cost of CNC machining?

If you’re here expecting a simple one-size-fits-all answer like “$75/hour flat,” I hate to break it to you—it’s not that straightforward.

But don’t worry. In this guide, We will pull back the curtain on:

- What drives CNC prices up or down

- Real industry-standard hourly rates

- Hidden costs no one talks about

- How we at Premium Parts help you save money without cutting corners

Let’s discuss CNC pricing, make sense of all the moving parts, and help you come out ahead; without sacrificing quality or time.

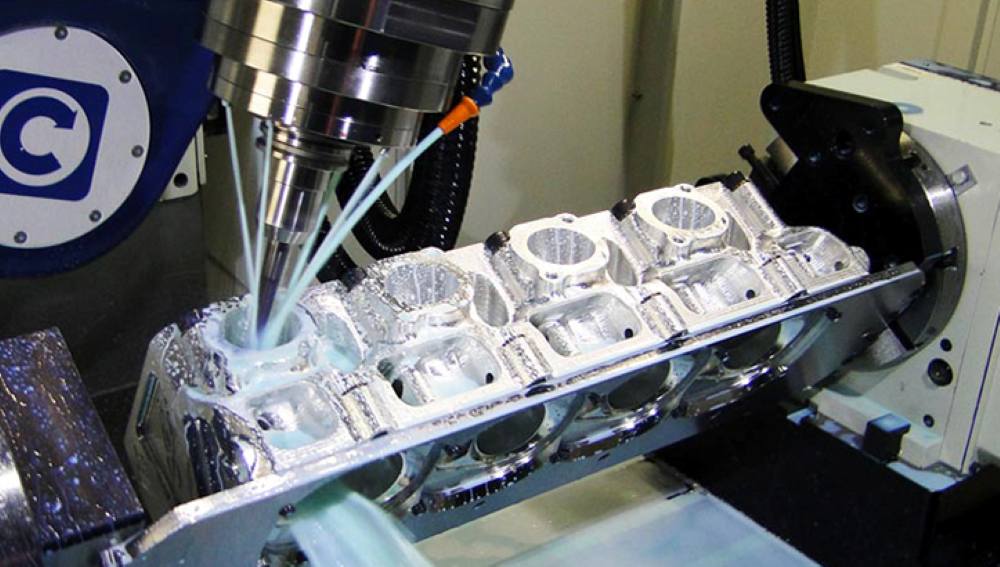

CNC Machining Overview (Why It’s Still the Gold Standard)

Before we discuss the pricing rabbit hole, it’s worth taking a moment to understand why CNC machining continues to dominate the product development cycle, and contemporary manufacturing world.

CNC stands for Computer Numerical Control. It’s a fancy way of saying the machines are run by computers, not people turning knobs manually.

Here’s what really happens:

You take your CAD (Computer-Aided Design) file—a 3D model of your part. You feed it into a CNC machine. And that machine? It goes to work with military precision, cutting, and shaping your part out of a solid block of material.

Whether it’s a piece of aluminum, stainless steel, titanium, or even plastic, CNC machining is all about subtractive manufacturing—you start with more, and cut away to perfection.

But here’s why it’s still the go-to option for engineers, designers, and manufacturers all over the world:

CNC Machines Are Precision Beasts

We’re talking micron-level tolerances. That’s thinner than a human hair.

In industries like aerospace, automotive, and medical, that level of accuracy isn’t a luxury; it’s a necessity. Because, a slight deviation can mean a failed part. So, a regulatory headache, or worse, a safety risk. CNC machines help avoid all of that.

Speed, Repeatability, & Automation Efficiency

Once the machine is set up and dialed in, it can make one part or one 1000 with identical results. No chances of deviation.

That kind of repeatability is what makes CNC machining ideal not just for prototypes, but also for small-to-mid-to-bulk volume production runs.

Human Expertise Still Counts

While CNC machines do the cutting, skilled operators and engineers are still the backbone of great machining.

They:

- Program the tool paths

- Select the right tooling

- Calibrate machines for accuracy

- Inspect the finished parts for flaws

So yes, CNC machining is high-tech, but it’s also highly human.

But Precision Has a Price

All this tech and talent doesn’t come cheap. You’re not just paying for machine time—you’re paying for:

- Years of engineering expertise

- Calibrated inspection systems

- Reliable lead times

- High-quality output

Think of it this way: CNC machining is like hiring a Michelin-star chef to make you dinner. Sure, it costs more than fast food—but the outcome? Next level.

That’s why when we talk about CNC machining costs, we’re not just throwing out hourly rates—we’re unpacking what’s behind those numbers.

And that’s exactly where we’re heading next.

What’s the Hourly Cost of CNC Machining?

Here’s the million-dollar question (well… more like $50 to $200 per hour):

“How much does CNC machining cost per hour?”

The short answer: It depends.

The longer, more useful answer: It depends on several key factors.

Let’s break it down.

Most CNC machining shops charge anywhere from $35 to $200 per hour, depending on:

- The type of machine (more on that shortly)

- The material you’re using

- The part complexity

- The required tolerances and finishes

- The volume of your order

- And where the machining is physically happening (yep—geography affects pricing, too)

But here’s the real kicker: hourly rates are only one piece of the puzzle.

Think Beyond the Hourly Rate

Let’s say Shop A quotes $80/hour and Shop B quotes $120/hour.

Shop A looks like the better deal, right?

Not always.

What if Shop A needs 10 hours to finish your part, while Shop B only needs 5 because they use a more advanced 5-axis machine?

Suddenly, Shop B is the better option.

Total part cost = hourly rate × hours spent

That’s the math you really want to look at.

What You Get with Premium Parts

At Premium Parts, our hourly rates start at $40/hour and scale depending on your part complexity, material, and machine time.

But we do things differently.

Rather than hand you a generic rate sheet, we take a consultative approach:

- We analyze your design

- We determine the best material/machine match

- We provide free DFM (Design for Manufacturability) feedback before production even starts

This means we help you reduce costs before you ever pay a cent.

Our team’s goal? Precision + affordability, not one or the other.

Real Talk: You’re Not Just Paying for Time

Let’s be clear: CNC pricing isn’t like hiring a freelancer by the hour. You’re not just paying for someone to sit at a machine.

You’re paying for:

- Advanced, multi-axis machines that cost six figures

- Experienced engineers and machinists

- Setup and programming time

- Tooling wear and tear

- Quality inspection and part validation

- And sometimes, post-processing like anodizing or polishing

So yes, the hourly number matters—but what matters more is understanding where that number comes from.

And guess what? We’re about to get even deeper into that by breaking down what’s inside that CNC hourly rate.

CNC Cost Breakdown: What You’re Really Paying For

Let’s pull back the curtain and break down what goes into that hourly rate:

1. Machine Type Matters—A Lot

Different CNC machines = different capabilities = different costs.

Here’s a quick breakdown:

| Machine Type | Typical Use | Hourly Rate |

| 3-Axis CNC Mill | Basic parts, 2D profiles | $40–$80 |

| 4-Axis CNC Mill | Slightly complex parts | $60–$100 |

| 5-Axis CNC Mill | Complex geometries, aerospace/medical | $100–$200 |

| CNC Lathe | Cylindrical or turned parts | $40–$85 |

| Swiss Lathe | Small, high-precision components | $80–$120 |

At Premium Parts, our Dongguan facility houses a diverse fleet of 3-, 4-, and 5-axis machines, including high-speed mills and Swiss lathes. We select the most cost-efficient machine for your part — not just the most expensive one.

That’s how we keep costs competitive and outcomes premium.

2. Material Type Influences Time and Tool Wear

Let’s say you need an aerospace part in titanium. That’s going to be harder to machine than aluminum, and it’s going to wear down tools faster.

Here’s how common materials affect hourly costs:

| Material | Machinability | Impact on Cost |

| Aluminum 6061 | Excellent | Low |

| Stainless Steel | Moderate | Moderate |

| Titanium | Poor | High |

| Brass | Great | Low |

| ABS, POM (plastics) | Easy | Low |

Want to save on cost? We’ll help you pick materials that hit your performance needs without spiking your machining hours.

3. Tolerances and Finishing – The Silent Cost Creepers

You might not notice it on paper, but tighter tolerances mean higher costs.

Think about it:

- More inspection time

- More precision per tool pass

- More chance of part rejection

Same goes for finishes. If your parts require anodizing, bead blasting, or polishing, those steps are added after machining—and they come at a price.

At Premium Parts, we quote everything upfront and transparently, so you’ll never get caught off-guard by extra fees.

4. Quantity Ordered

Here’s a CNC insider secret: Setup takes time.

When you order just 1 or 2 parts, that setup cost gets baked into the price. But when you order 20, 50, or 100 parts, we spread that cost over the full batch.

More parts = lower hourly cost per part.

That’s why Premium Parts specializes in low-volume manufacturing. We strike the perfect balance between one-off prototypes and high-volume production—keeping prices lean and timelines fast.

5. Design Complexity

The more tool changes, tight corners, and complex geometries in your design, the longer it takes to machine.

A basic bracket might take 10 minutes. A multi-axis, thin-wall enclosure with undercuts might take 4 hours.

Don’t worry, we won’t just take your file and run it blindly. Our team of engineers (with 15+ years of CNC expertise) reviews every part for cost efficiency.

If we can machine it faster or smarter, we will. And we’ll tell you how.

CNC Machining Cost Per Hour by Country

Location matters. Labor costs, machine availability, and overhead all vary globally.

Here’s what you might expect:

| Country | Average Hourly Cost |

| USA | $75–$200 |

| Canada | $70–$180 |

| UK | $60–$150 |

| Germany | $70–$160 |

| China | $30–$90 |

That’s why many global brands choose to outsource CNC work to China—especially when quality isn’t compromised.

At Premium Parts, we offer global-standard quality with China-based efficiency, giving you access to skilled labor, advanced machines, and unbeatable turnaround—all under one roof.

How to Lower Your CNC Machining Costs Without Losing Quality

Want to know how smart product developers keep machining costs down?

Here’s how we guide our customers:

1. Optimize Your Design

Keep your design simple and avoid unnecessarily tight tolerances. For instance:

- Thin walls

- Deep pockets

- Unnecessary sharp internal corners

Instead, use radii, reduce cavity depth, and keep consistent wall thicknesses.

We offer free DFM reviews to all customers so you can avoid costly design flaws before production begins.

2. Choose the Right Material

Aluminum or POM can often replace stainless or titanium for non-critical parts.

We’ll help you match performance with price.

3. Batch Your Orders

Instead of ordering 2 parts every week, try combining them into a 10-part monthly batch.

Setup costs drop, and your part price improves.

4. Work With a Trusted Partner

Not all suppliers are equal.

You need a manufacturing partner who values transparency, offers design help, and ensures quality throughout.

That’s exactly how we’ve built long-term relationships with clients in the automotive, aerospace, medical, and consumer electronics industries.

Why Premium Parts Is a Smarter CNC Choice

Let me level with you. CNC machining is more than just cutting metal. It’s about:

- Speed to market

- Tolerance control

- Communication

- Reliability

- Engineering support

At Premium Parts, we offer a complete manufacturing experience. Here’s what makes us different:

- Experience: Our engineering team has 15+ years in CNC machining, DFM, and rapid prototyping.

- Fast Quotes: We reply within 24 hours, sometimes within hours. You don’t wait.

- Rapid Lead Times: Parts delivered in as little as 3–5 days, worldwide.

- Global Clients: We serve leading companies in the S., Canada, the UK, and Italy.

- Diverse Capabilities: From CNC and sheet metal to plastic injection and rapid tooling — we do it all in-house.

- Reliable Quality: Our facility follows ISO-level quality systems and uses calibrated inspection equipment for accuracy.

- No Hidden Costs: Transparent pricing, no surprise charges, full breakdowns in your quote.

Real CNC Cost Examples from Premium Parts

Want real-world insight? Here’s what some of our recent projects cost per hour:

| Project Type | Machine | Material | Hourly Cost |

| EV battery bracket | 3-axis | Aluminum 7075 | $50/hour |

| Aerospace mount | 5-axis | Titanium | $145/hour |

| Medical prototype | Swiss Lathe | SS316L | $90/hour |

| Consumer product housing | 3-axis | ABS Plastic | $40/hour |

Each part had different complexity and tolerances—but every one of them was delivered on time, within budget, and to spec.

CNC Machining is an Investment, Not a Cost!

The goal isn’t to find the cheapest machining rate.

The goal is to find the right partner who delivers the best part, at the right time, for the right price.

At Premium Parts, we treat every project like a partnership—not a transaction.

- We listen

- We suggest better ways to machine your part

- We communicate clearly and often

- We meet deadlines

- We deliver excellence — every time

Need a quote or want to discuss your next CNC project?

Contact us today and let’s build something precise, meaningful, and cost-effective, together.