Why You Should Use Custom Resins for Your Injection Moulding Process? While CNC machining and 3D printing continue to advance at relatively rapid rates, the same cannot be said for injection moulding. Injection moulding is one of the most robust, conventional plastic manufacturing methods that is all too well-grounded, tried, and tested for sustainable results. That says injection-moulded parts will continue to see reasonable improvements around product quality, cosmetic finish, and part performance.

Today, our emphasis moves from simple injection moulding to custom moulding processes. Our highlight, custom resins, refers to engineered resin materials made to the customer’s specification on demand to deliver specific visual, cosmetic, functional, strength, and even cost characteristics. With the already extensive list of options to pick your resin or polymer from, you may wonder what the need for a custom resin is. The answers to all your questions are covered in today’s topic. Read on to find out why you should consider custom-engineered resins in your injection moulding process.

1. Uniform Production Quality

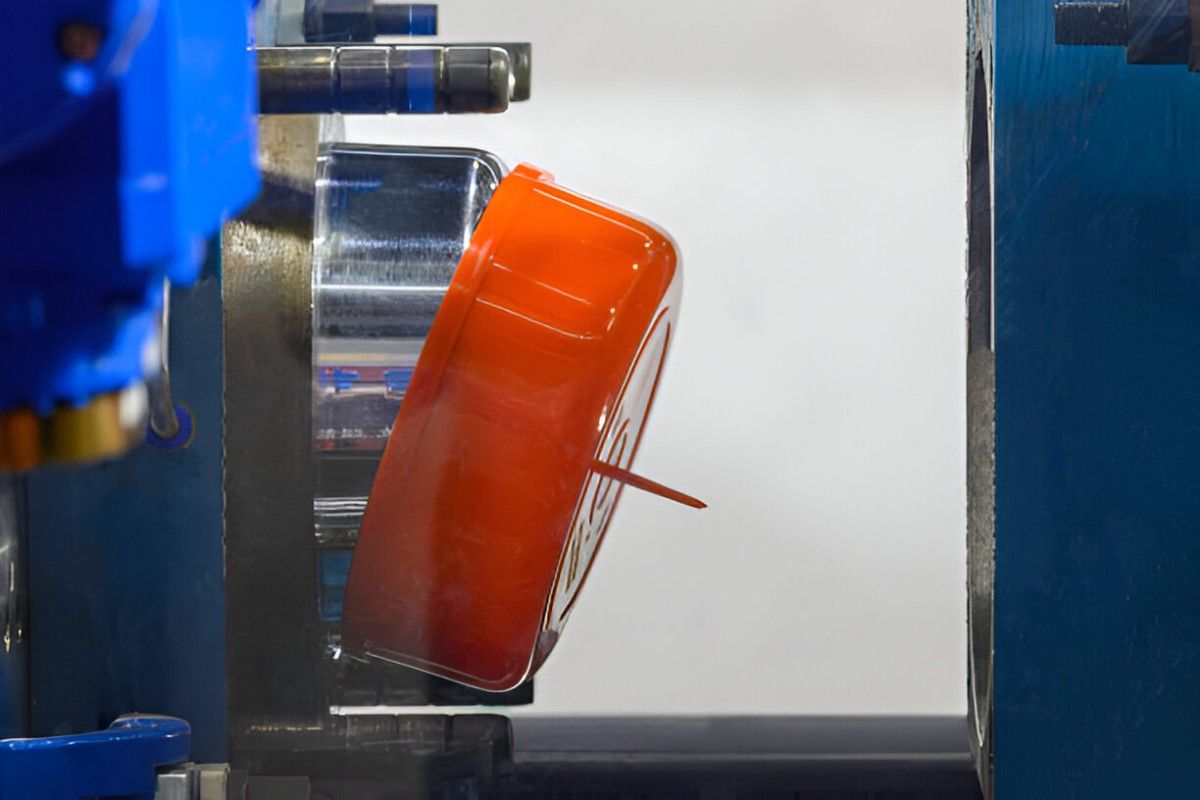

Plastic Injection Moulded Bowl

Plastic Injection Moulded Bowl

Image Description: The plastic bowl parts production process by an automatic system from a plastic injection mould machine

Customised resins are polymers and resins manufactured to meet specific quality grades and characteristics that enable them to fulfil their end-use functions. One of the benefits of having a proprietary designed resin is the level of consistency you will have in your injection-moulded parts. Because your resins are not standard plastic polymers sourced by suppliers, the likelihood of having differences in your supply is significantly reduced.

A custom resin should also translate to uniformity in product quality, as the raw materials employed are all of the same grades. Suppose you have any differences in the quality of your end parts. In that case, the process parameters for each production batch are likelier to be the culprit and not your raw material of custom-made resins.

2. Cost Savings in the Longer Run

Plastic Injection Mould Setup

Plastic Injection Mould Setup

Image Description: Metal Mould or plastic injection mould setup on a high-pressure injection moulding machine for mass production.

Depending on the type of resins you’re developing, the cost of engineering a polymer or composite resin to match specific end-use purposes can be a bit on the upside. No doubt, there are also the initial research and development costs that must be factored in. Thankfully, these are all one-off fees.

In the long run, your custom resin approach can leave you with the perfect material for your project in terms of a range of factors, from chemical resistance, rigidity, flexibility, to material stability, strength, shock, and impact resistance. From a cost perspective, developing a custom resin will be more cost-effective than opting for high-grade materials with the desired attributes, which are often limited in supply and have higher costs. Custom engineering also allows you to pick the most critical attributes in a material without incurring the high costs of selecting materials that have it all. For instance, it would be far more affordable to enhance a resin’s rigidity than to purchase a super resin with an array of unwanted properties to tap into that material’s rigidity. In the long run, you want to end up paying for materials that possess some of the desired properties and a list of unnecessary characteristics. Considering large-scale manufacturing, the cost savings of having a custom resin far outweigh the choice of ready-made resins in the long run.

3. Increasing Supply Options

Manufacturing your custom resin can help you reduce overdependence on a particular supplier and widen your options. This way, you can always work with different material engineers to have your resin formulated and ready in time for production.

Developing a proprietary material can also mean more control over your supply, working with additional manufacturers, and avoiding market uncertainties or discontinuation of resins, modifiers, and fillers. Additionally, resin manufacturers may make certain subtle modifications to resins without prior notice to customers. No matter how small, these changes may affect the quality of your parts.

The ultimate benefit of designing and holding your own resins is the patent and secrets that you get to keep. It can be a significant factor when looking to cut product adulteration and counterfeits in your line of business.

Premium Parts Injection Moulding Services in China

Premium Parts provides excellent injection molding services for all its customers in China. From material selection, process optimisation, and cost reduction, we ensure that we work with all our customers to deliver high-quality moulded parts on time and at the most cost-effective rates.

We understand the essence of product manufacturing, which is why we strive to consistently deliver parts that meet specifications, offer enhanced functionality, and a superb finish. Ready to work with us? Please feel free to contact us for a free quote!