Test fixtures offer gadgets stability in the course of testing and provide the equipment with an optimal angle. The consistent positioning reduces variability and increases accuracy in measurement. Effective fixture designs incorporate materials for a particular testing condition. This thoughtful design is then beneficial to product quality and making consistent operational outcomes. This article focuses on test fixture design in the manufacturing of electronic components.

Emphasizing fixture design in electronic manufacturing has several reasons. Components need to be positioned in a consistent and repeatable manner for incrementing precision and accuracy. This is implemented by fixtures when performing programmed tasks. The effective design reliability greatly minimizes the likelihood of experiencing bottlenecks during production. In device production, fixture designs are critical, and when the manufacturing of the devices increases, the fixture designs must also be efficient to enhance throughput. All industries, ranging from medical devices as large as the human body and including aerospace components down to small consumer electronics, require testing to ensure quality and reliability. These testing processes are highly dependent on the appropriate fixture design.

However, to achieve the best outcome, the design of fixtures in electronic manufacturing should be done through professional engineering. Ideally, professionals should have a good understanding of concepts such as Design for Manufacturability (DFM) and Design for Testability (DFT).

Types of Setup For Fixture Designs

Test Fixture Setup

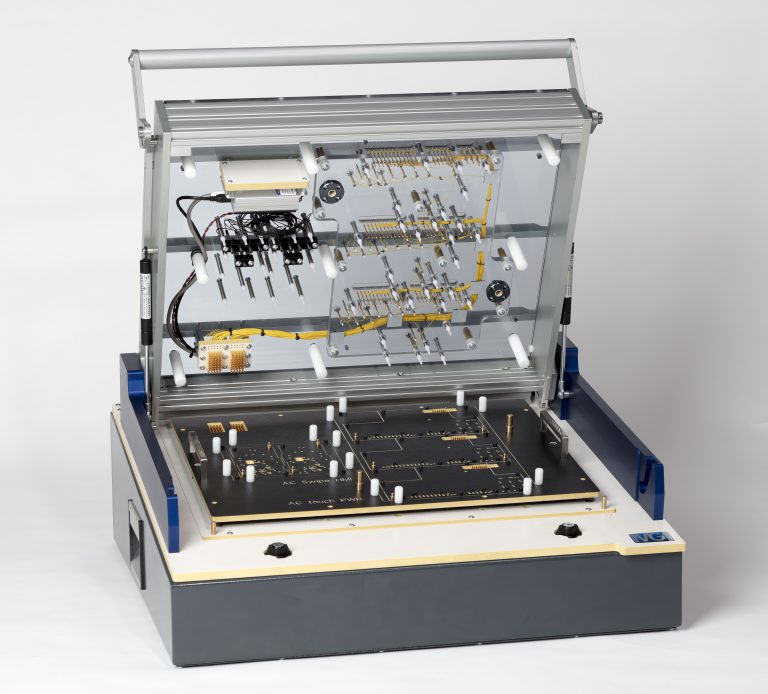

Image Description: A Close-up view of the fixture arrangement.

Test fixtures can be organized in three distinct ways: In-line, delegate, and implicit. Every setup approach has its pros and cons, as well as the right applications. The selection of the correct method determines the testing process in a given project. Understanding all these methods is crucial in test management. An optimal choice results in the best possible testing scenarios.

1. In-line Setup

In-line setup incorporates the test fixture in the same method as the tests in a program. This makes the approach easy to perform, especially for smaller test suites. Since the procedure is kept simple. Redundancy may occur, particularly when several tests call for the same preliminary information. Some critical issues may be faced when maintaining includes: over time, there may be some duplicity of the systems. The process of testing is made less complicated by using diligent attention when making decisions.

2. Delegate Setup

Delegate setup moves the test fixture to a different helper method. This setup can be accessed by various test methods and encourages code reuse more or less effectively. One of the primary benefits of this setup is that it eliminates the redundancy in the tests and improves organization. In addition, the codebase becomes a lot clearer when seen in a clean, organized manner. In general, the quality of maintenance and scalability when testing is improved by employing this delegate setup in fixture design.

3. Implicit Setup

Implicit setup uses a single setup method to set up more than one test. This way of creating test fixtures in one place has cut down code duplication to a very large extent. The coordination of multiple tests within a single framework is easier. The method can be seen to improve test coherence significantly better than the delegate setup approach. Finally, improved testing procedures result from this systematic structure.

Custom Test Fixture Design: An Overview

Fixtures are relatively less complex than equipment in terms of design. The two terms are sometimes used interchangeably. Although certain factory machines are the fixed assets of a business, they are not considered fixtures. Small drilling jigs, in the same way, are not considered equipment. The term “test fixtures” refers to fixtures used only for testing applications. They can be used to measure several features, such as the straightness of a shaft and device efficiency. Not all fixtures are test fixtures. Non-test fixtures are those that incorporate tools, typically used to disassemble any component for performing delicate drilling.

In most cases, test fixtures do not possess automation and motion control. They are frequently either fixed in place. It may need to be activated by hand. Heavy materials such as aluminum, stainless steel, or plastic like Delrin are used in making test fixtures. Most of the fixtures are made by precision CNC machining, so that the specific elements required are provided within a thousandth of an inch. This precision guarantees interaction with the devices in the right manner.

Types of Test Fixture Design

Let’s figure out some common types of test fixture designs.

Manual Test Fixtures

Manual Test Fixture

Manual Test Fixture

Image Description: Open view clearly showing terminals and internal elements of the manual test fixture.

Manual test fixtures involve the use of manpower to perform the setup and fixture running. These are typically basic designs to facilitate positioning by technicians of devices. Normally, these fixtures are applied to low-cycle and prototype testing, where flexibility is notably the highest priority. Examples of manual fixtures are: adjustable supports, which would be used to fit the different sizes and positions of the devices.

Automated Test Fixtures

Automated Test Fixture

Automated Test Fixture

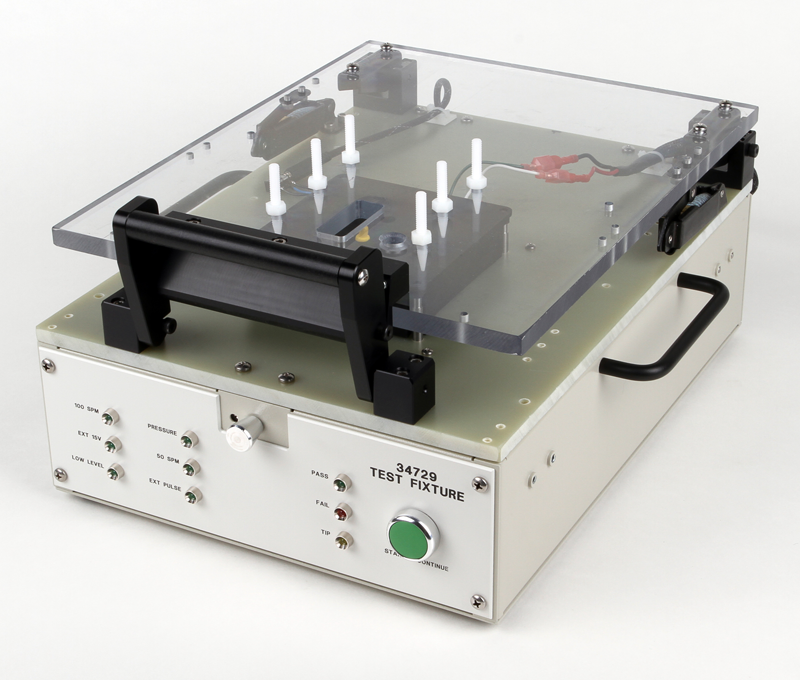

Image Description: The Image depicts an automated test fixture with control buttons clearly on a white background.

Automated test fixtures are those fixtures that use robotics or mechanical operations to control the test processes. These fixtures improve speed and uniformity while at the same time reducing the possibilities of human intervention. Usually, used in manufacturing lines and integrated with sensing and control elements to run short and accurate test cycles. Many of the automated systems work hand in hand with software used in data gathering and processing.

Fixed Test Fixtures

There are devices that themselves offer support for specific devices, and these are known as fixed test fixtures. They do not have any flexibility at all in terms of orientation. They are designed for repeated testing, and in many cases, are built specifically to match the size and hardware interfaces of the DUT. These fixtures are vital in applications and need high precision and reproducibility of measurements.

Modular Test Fixtures

Modular Test Fixture

Modular Test Fixture

Image Description: The Image shows the fixture with step-programmable parameters clearly visible.

Modular test fixtures are built from separable subassemblies. These are quite flexible and can be changed quickly. Their design ensures that several devices can be tested without necessarily having to be redesigned greatly. Suspended luminaires can sometimes include universal mounting structures guaranteeing that different modifications can be made easily to suit the specific testing needs without compromising the stability of the fixture.

Multi-Use Test Fixtures

The equipment can be tested within a single setup, and therefore, multi-use test fixtures are developed. PTs defined by these fixtures tend to have changeable elements, either adjustable on the unit or exchangeable altogether for other components. Their flexibility optimizes resource usage and minimizes the cost burden of managing several specialized fixtures.

Thermal-Resistant Test Platforms

Thermal chamber test fixtures maintain the thermal environment in which the DUT is tested at a specific temperature. Most of these fixtures are fitted with heating and cooling elements to mimic the conditions in real operating circumstances. They are significant in making performance assessments and device dependability under various thermal conditions.

Electrical Test Fixtures

Electrical test fixtures are used for testing electronic components and circuits and are designed for that purpose only. Such fixtures are generally designed with power supply and signal measurement connection points so that the electrical tests can be performed effectively. Additional features may be automatic switching systems to enable several test scenarios without the need for human intervention.

Advantages of Test Fixture Design

- Helps conduct repeatable tests that impose similar conditions, and therefore improves reliability.

- Improves better organization of the functions in a modular manner, to ease the process of maintenance.

- Allows multiple test codes to be recycled, making the process faster.

- Used to set tests to a specific starting condition, which limits variability.

- Reduces carryover effects, which may distort the results that are being obtained.

Disadvantages of test fixture design

- They may result in the creation of multiple test fixtures, which may be hard to manage.

- Inline setup can lead to problems of maintenance and also enhances the complication level.

- Parallel testing increases the risk of errors when executing tests because of redundancy.

- More fixture complexity could be detrimental to good code organization.

- It should be well thought out to avoid blurring of the goals and objectives of the respective systems.

Ways to Mitigate Common Risks While Designing Test Fixtures

It’s crucial to observe best practices when using test fixtures. The problem with overly general implicit test fixtures is that they can lead to confusion when a test method sets up a fixture but never actually uses it properly. Furthermore, it is also possible to provide hints, which allow ignoring certain fields within a fixture and, therefore, receive inaccurate test results. Reducing the complexity of test setups is essential, and even more so in in-line configurations, where the number of important features has to be emphasized. Safety concerns have to be taken into account when designing tests. Changing fixtures should not affect the next tests. Aberrant from these practices will help towards more accurate and efficient testing results.

Essential Parameters and Acceptance Standards for Test Fixtures

Here are some crucial parameters to consider for maximizing outcomes.

Design Considerations

In essence, an effective design of test fixtures has the following technical considerations. First, dimensional accuracy in the first three dimensions is essential; fixtures must be in direct contact with the testing machine under test to avoid movement during testing. The material type used in fixtures is also important; fixtures should be made from hard-wearing materials like aluminum or stainless steel to be able to endure cycling without developing signs of wear.

Test point accessibility has to be a design priority. The designs must not hinder the connection of the hardware to measuring instruments; time is precious. In addition, the fixture should be adjustable in one way or the other to suit a particular device or a particular test type.

Acceptance Criteria

There is a strong need to set stringent acceptance norms to assess the efficacy of the test fixtures. The fixture must be in a certain position, and this position has to be measured and confirmed by calibration processes. Another important measure is repeatability; fixtures must provide similar results in successive tests, thus excluding a source of variation in measurements.

Another criterion should be ease of use, meaning designs that make setup and use as simple as possible. If user interfaces exist, they should be easy to understand so that there is little need for training.

Performance Evaluation

Subsequent performance evaluations are required to sustain fixture dependability. Fixtures need to be able to withstand everyday usage and different demographical conditions such as temperature and humidity. Bi-monthly checkup is recommended to identify signs of wear and tear and the overall efficiency. Thus, the user’s feedback can also be beneficial for making further iterative changes to increase effectiveness.

Documentation and Guidelines

Documentation is an essential practice to support the right use of test fixtures. Such recommendations should include the procedures for setting up the product, the operational procedures, and the maintenance procedures. Proper documentation creates uniformity among the users in the way they use fixtures, which in turn retains their quality, hence achieving accurate testing results.

Conclusion

Test design fixtures are required for high accuracy and repeatability in the manufacture of electronics. They offer the test a firm base and a predictable posture, which is very important in improving the test’s reliability. They are used in many fields ranging from aerospace and automotive to electronics, where quality is a major concern. Proper fixture design reduces error rates and costs because the work environment is designed to fit the human body. Involvement of competent involvement with knowledge of DFM and DFT leads to promising design. In conclusion, good test fixtures yield a quality product and defined processes of production.

FAQ’s – Test Fixture Design

Q1. What are Test fixtures, and their purpose?

The primary role of a test fixture is to provide support to the devices during testing. It’s important to make certain that the item under test is well-positioned and aligned during the test process. In this way, stability is also preserved by fixtures, it minimizes measurement errors. In general, fixtures have a key role in the process of obtaining accurate test outcomes.

Q2. How do test fixtures improve production efficiency?

Test fixtures improve production efficiency because they offer components a standard orientation. This ultimately reduces the time needed to set between tests as compared to the time needed to set for a single test. When the variability of the results is reduced, then the testing process becomes more efficient. All this in turn results in shorter production cycles and better overall productivity.

Q3. What role does automation play in test fixtures?

Automation in test fixture designs greatly improves the speed and accuracy of tests. Robotized processes can execute monotonous work in an organization without human interference. So, mishaps or interventions by humans can be reduced. Moreover, the technology makes it possible to collect and analyze data within a shorter period. Therefore, manufacturers can produce more throughput without compromising on quality standards.

Q4. Why is it important to consider environmental conditions in fixture design?

It is argued that fixture design should take environmental conditions into account for the testing to be precise. The environment also has inputs for devices and their tests, such as temperature and humidity.

Q5. How can fixture design impact product quality?

Fixture design has a close relationship with product quality due to the testing process. Properly designed tools enable accurate measurements and performance evaluation. As a result, the identification of defects or inconsistencies becomes easier during production.