How can manufacturers reach tight part tolerances while maintaining their parts’ accuracy? Why do many industries prefer CNC machining over conventional means? The answer lies in its speed, repeatability, automation, and minimal turnover. Traditional machining struggles to produce consistent parts, which often leads to waste and production errors.

CNC Machines encompass computerized commands. It has automated milling, shaping, and cutting. Unlike traditional techniques, these end up with precise and desired outcomes. The technology is continuously evolving. Multi-axis CNC machining can produce complex shapes within a single setup. Moreover, advanced tooling and high-speed spindles have significantly reduced waste material and operation cycle time. As a result, manufacturers can now shape premium quality parts with little to no waste production.

This blog will give manufacturers, engineers, and machinists valuable machining insights. Specifically, we explore primary CNC operations, major types, selection criteria, cost considerations, and future trends. Whether making small parts or upgrading your production, this guide will help you make the right choice to improve your manufacturing process.

What Is a CNC Machine?

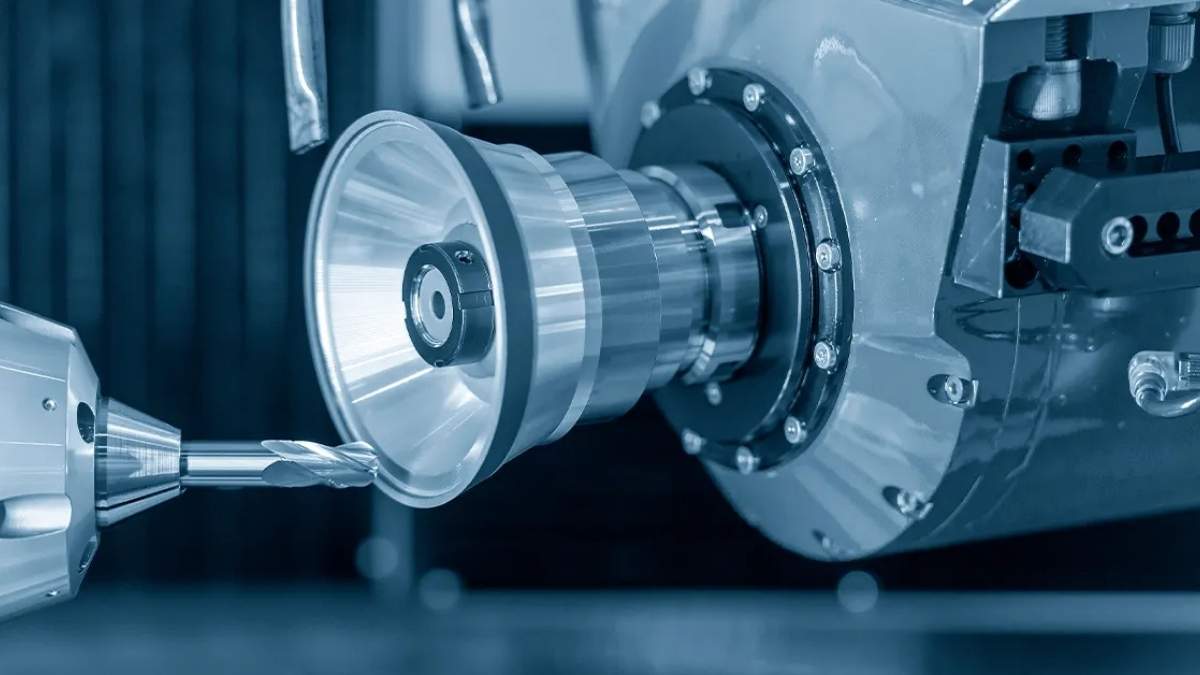

CNC Machining

Image Description: A CNC machine tool actively shapes a metal workpiece that rotates steadily on its axis.

CNC machines involve computer commands to perform operations—these programmed G-codes direct tool paths to shape raw materials into tangible products. The primary components of a CNC machine comprise the control system, motor controls, spinning equipment, and tooling. Such systems produce faster and more accurate results with minimal waste.

CNC machining begins by creating CAD (Computer-Aided Design) models or a 3d footprint. The software converts the CAD-based instructions into machine-readable output.

Next, the CNC system operates the cutting tools according to pre-defined instructions. It utilises sensors to monitor operational parameters and ensure precise results. The system operates under operator guidance, minimising human contact with the process.

Key benefits of CNC machines:

- High precision and repeatability for consistent part quality

- It will save you on material waste, as it usually produces minimal to no waste.

- The automated system delivers work orders faster than manual techniques

- It protects workers since it minimizes tasks that require physical contact with materials

- Automation eliminates manual intervention, makes operations run faster, and reduces the production cycle.

At Premium Parts, our manufacturing faculty has cutting-edge CNC machines to offer you top-standard quality products. Our team brings over a decade of expertise to provide a high-end manufacturing solution within your constrained budget. Get to know more about our CNC Machining Services.

What Are The Common Types of CNC Machines?

Selecting the right CNC machine can make or break your machining work. With numerous CNC machine types available on the market, how do you determine which one best suits your needs? Some machines are designed for heavy-duty applications, while others are suited for small, intricate parts. Therefore, understanding the purpose of each option can help you make a more informed choice. Let’s examine different CNC machines and how each one contributes to machining.

CNC Milling Machines

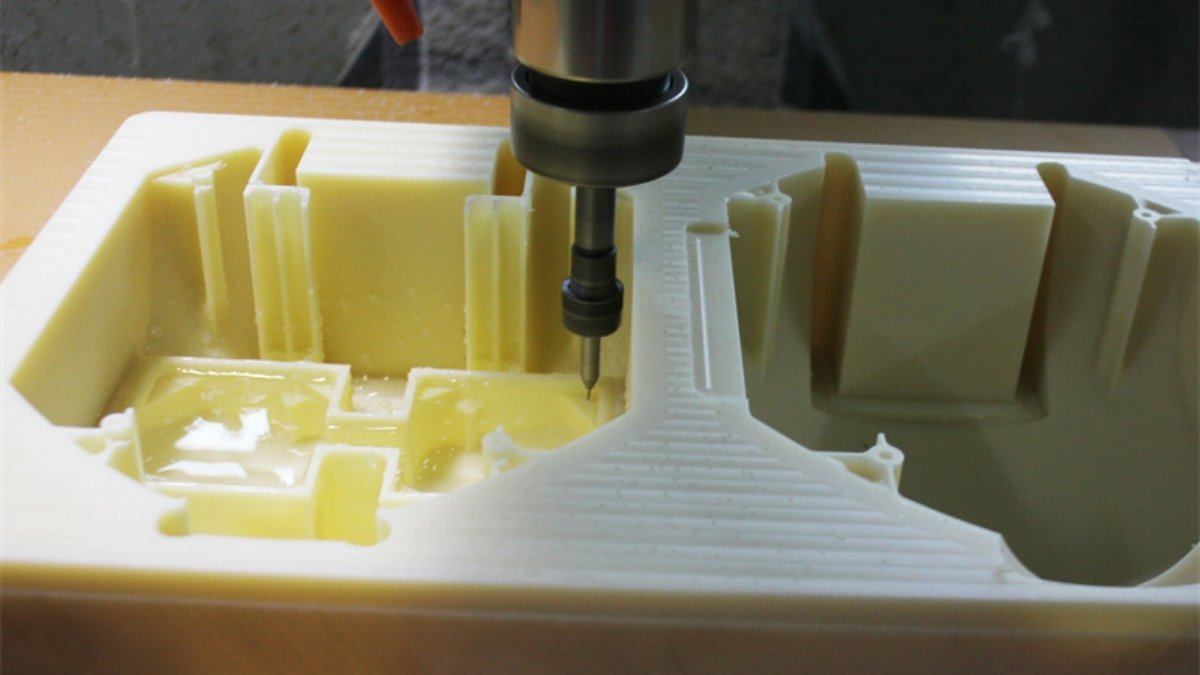

CNC Plastic Milling

Image Description: The image depicts a CNC milling machine cutting into a solid plastic block to create an enclosure.

CNC milling delivers the best results when creating detailed and complex parts. These devices use spinning tool cutters to transform metal pieces and other materials. Vertical mills are particularly useful for making small, detailed components, while horizontal mills process structural materials effectively. Several coordinated axes help you machine elaborate parts in fewer operations.

Additionally, the milling system produces parts with tight tolerances, consistently reproducing the same results while utilising raw materials efficiently. Therefore, aerospace, automotive, and medical firms depend heavily on CNC milling for exact measurements. Better control of tool motion, combined with higher feed rates and speeds, enables faster production. Setting up fixtures correctly helps the machine stay steady during operations. A CNC milling machine must be in your workshop if you value accuracy and precision.

CNC Lathes and Turning Centers

CNC Turing

Image Description: The image depicts a CNC turning process in which a metal workpiece is shaped as it rotates on a lathe.

CNC lathes are used for the highest precision in cylindrical part manufacturing. The machines spin work items during tool usage to create exact shapes on the material. If you need complicated profiles? CNC turning centres control multiple axes to create such geometrical shapes. The rapid rotation of the spindle produces smooth metal and polymer surfaces.

Industries such as aerospace, oil and gas, and automotive rely heavily on CNC lathes for their production needs. Moreover, machine changeover tools enable the production process to run efficiently. The type of software used during programming and the optimal selection of tools define how well the final surface appears. CNC lathes provide consistent, high-quality parts regardless of the thread, taper, or shaft shapes you need to shave off.

CNC Laser Cutting Machines

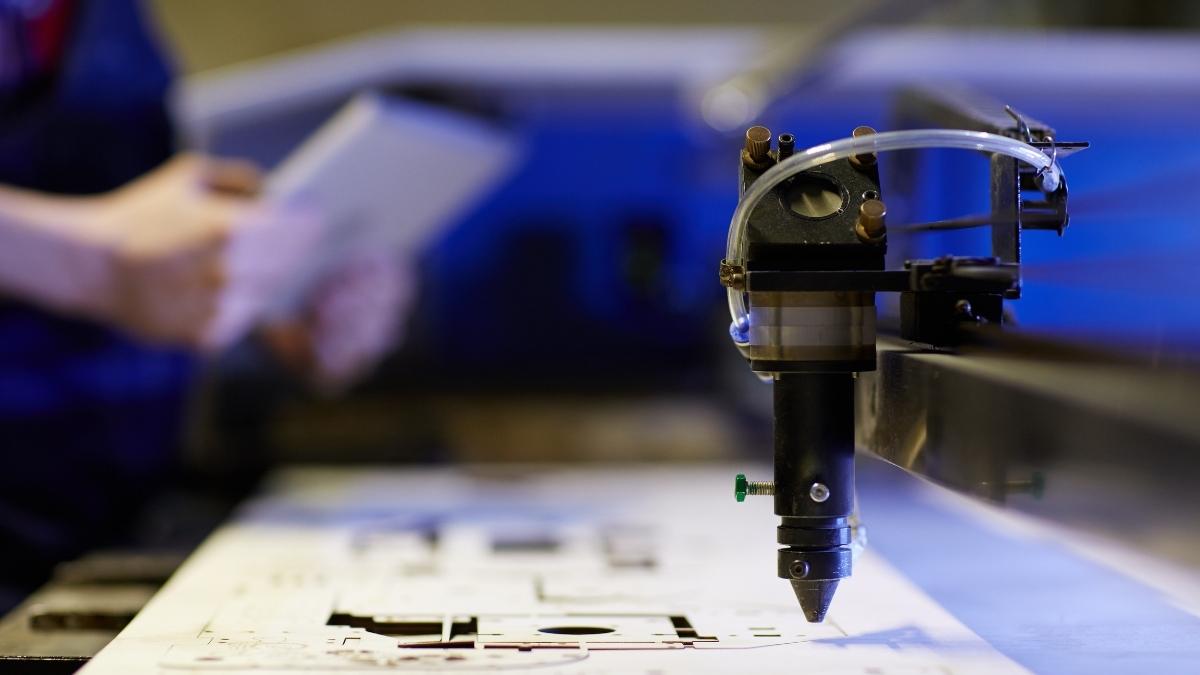

Laser Cutting

Image Description: The image shows an operator controlling a laser cutting machine during operation. The laser cuts through a flat sheet with precision.

Laser CNC machines are ideal for detailed work and high-speed cutting operations. These machines use high-focused lasers to cut parts with superior precision. Fiber lasers outperform all other variations of laser machines in metal cutting. However, CO2 lasers process non-metallic materials optimally. Compared with conventional cutting, their end product does not require post-machining.

Additionally, laser technology yields excellent results for signs and electronic components in medical equipment. These uses height detection technology to control production outcomes. As a result, setting the correct power levels and adjusting the gas flow helps produce more precise cuts. CNC laser cutting machines are the go-to option if you need accurate cuts with minimal waste.

CNC Plasma Cutting Machines

Plasma Cutting

Image Description: The image shows a plasma cutting machine cutting through a metal sheet. A high-temperature plasma arc moves along the surface and creates clean and precise cuts.

Need fast, efficient metal cutting? Plasma cutting can be the proper selection for you. These machines use ionized gas to cut through conductive metals such as steel and aluminum. HD plasma cutting produces precise edges with minimal metal residue. Companies that build ships, construct buildings, and manufacture heavy machinery rely on plasma cutting as their primary metal-cutting technique.

Moreover, the system maintains a stable arc path throughout the cutting process. However, for optimal cuts, the machine needs correct gas pressure settings, and the nozzle must be regularly cleaned. Plasma cutters can precisely handle large amounts of work quickly through manual and robotic operations.

CNC Electric Discharge Machines (EDM)

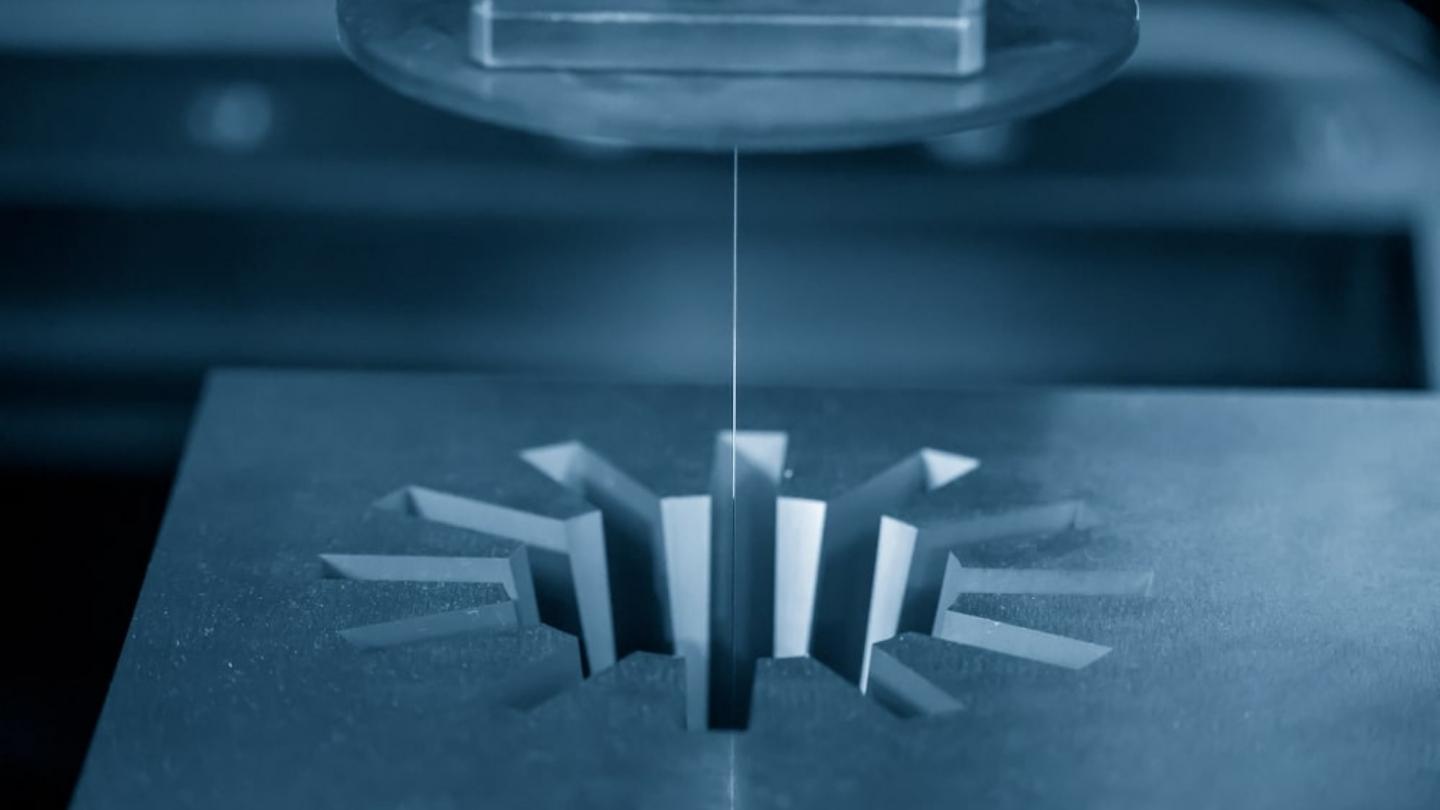

Wire EDM Machining

Image Description: The image shows a Wire EDM machine cutting through a thin wire using a metal workpiece.

Hardened steel and detailed cavities require EDM technology to achieve satisfactory results. The electrical discharge process removes material without applying mechanical pressure. These machines generally have two variations: Wire EDM produces delicate, profiled shapes, while sinker EDM creates large interior openings. Tool and die makers typically rely on EDM for precision work that necessitates tight manufacturing tolerances.

The aerospace and medical sectors rely on EDM to produce intricate parts. Further, Dielectric fluid maintenance controls the quality of the cutting operation. Unlike traditional techniques, EDM produces burr-free surfaces and sharp corners. When piercing hard materials, EDM provides precise results with minimal roughness.

CNC Waterjet Cutting Machines

Waterjet Cutting Machine

Image Description: The image shows a waterjet cutting machine in operation. It uses a high-pressure jet of water mixed with abrasive material to cut through a thick metal sheet.

If you are looking to cut materials without thermal damage, waterjet cutting can be a go-to option. These machines utilise strong water jets and abrasive additives to efficiently cut through metals and non-metals. Unlike plasma or laser cutting, waterjet technology avoids thermal distortion issues. The aerospace, medical, and automotive sectors depend on water jets for their exact cutting operations.

Additionally, multiple cutting directions enable the creation of intricate shapes by removing only small amounts of material. The machine system maintains pressure levels for steady cutting rates. Frequent cleaning of the nozzle helps the machine cut better and work longer. CNC waterjet cutting is the ideal option if you require higher quality and accuracy.

CNC Grinding Machines

Grinding Machining

Image Description: The image shows a grinding machine smoothing the surface of a metal object. The grinding wheel spins rapidly, removing material to achieve a precise finish, and the sparks are visible

CNC Grinding produces the best finishes and tightest tolerances in any manufacturing setting. These machines run abrasive wheels to smooth out different metal materials, including ceramics and hard alloys. Grinding machines produce cylindrical, surface, and centerless workpieces of specific types. Tool producers and aerospace businesses use grinding to meet demanding surface quality requirements.

The system automatically controls feed rates and wheel pressure to achieve optimal output results. Moreover, the fast-spinning tools improve material removal rates without harming your work area. Using the right amount of cooling and lubrication helps tools run at safe temperatures without damage. CNC grinding machines deliver precise results for applications that require high precision.

Special-Purpose CNC Machines

Certain tasks require specialized CNC machines beyond basic models. Multi-axis CNC machines enable the production of complex parts in a single setup. Hybrid CNC machines use an integrated approach. These combine milling and 3d printing to create advanced products. CNC routers work effectively with wood materials, as well as plastic and composite products.

The autonomous CNC machines produce exact hole positions during mass production runs. Robotics-integrated CNC systems streamline automation for mass production. Defense, medical, and automotive industries use these technologies as these specialized options help make the production process run better without compromizing on superior results when you need unique solutions.

Comparing CNC Machine Types

Choosing the right CNC machine typically depends on your production requirements, the material, and the desired end quality. The following tables outline the major differences, helping you choose the best CNC machining for your work.

| CNC Machine Type | Best For | Precision Level | Suitable Materials | Applications |

| CNC Milling Machine | Complex geometries, slotting, and drilling | High | Metals, plastics, and composites | Aerospace, automotive, medical |

| CNC Lathe & Turning | Cylindrical parts, threading, shafts | Medium to High | Metals, polymers | Oil & gas, aerospace, automotive |

| CNC Laser Cutting | High-precision intricate cuts | Very High | Metals, plastics, and composites | Electronics, signage, and medical |

| CNC Plasma Cutting | Thick metal cutting, fast production | Medium | Conductive metals (steel, aluminum) | Shipbuilding, construction, heavy machinery |

| CNC EDM | Intricate cavities, hardened materials | Very High | Metals only | Aerospace, tool & die making |

| CNC Waterjet Cutting | Heat-sensitive material cutting | High | Any material (metals, glass, stone) | Aerospace, medical, automotive |

| CNC Grinding | Fine surface finishing, tight tolerances | Extremely High | Metals, ceramics, hardened alloys | Automotive, aerospace, and tooling |

| Special-Purpose CNC | Custom applications, multi-process machining | Varies | Varies based on type | Medical, defense, and manufacturing automation |

Factors to Consider When Selecting a CNC Machine

The foremost requirement in selecting CNC machines depends on the materials, along with production tolerances and manufacturing requirements. Analyzing these elements leads to maximizing performance, cost reduction, and extended machine reliability.

Material Compatibility

All CNC machines possess limited capabilities regarding the materials they can process. For example milling machines demonstrate their best performance by processing metals as well as plastics and composites. The optimal application of lathes is for working with cylindrical metal and polymer parts.

The plasma cutter specializes in working with heavy conductive metals, but laser machines provide precise cutting capabilities for thin sheets. A correctly selected CNC machine protects your tools from wear while improving operational efficiency and sustaining product quality.

Accuracy and Precision Requirements

Machining tolerance and precision refer to permissible errors. Most manufacturing tasks require the precise capabilities of milling machines and lathes. The laser cutting process produces precise details while maintaining consistent material shape. The machine owner must verify all aspects of repeatability and resolution control system capabilities. Highly complicated and delicate part geometries increase in cost, resulting in error-free parts with minimal mistakes.

Production Volume and Speed

For high-production runs, consider the machine’s turnover and automation level. Complex manufacturing operations finish more swiftly through multi-axis CNC mills and turning centers. Sheets can be processed at high speed by plasma and laser cutters. This makes them an optimal choice for bulk manufacturing requirements. While the speed of waterjets is lower, yet they maintain the ability to cut multiple material types. Both robotic loading systems and automatic tool changers intensify machine cycles by speeding up production time.

Cost and Maintenance Considerations

The costs for startup investments, combined with running expenses, vary for each type. The initial cost for CNC milling and lathe machines remains affordable, even though users need to replace their tools periodically. The operation of laser and plasma cutters demands regular maintenance tasks for their lens and nozzle components.

The operating expenses of EDM machines increase because of electrode wear. The operation of waterjets requires the continuous use of abrasives, which raises operational expenses throughout their service period. Machines that require minimal maintenance enable better profitability through decreased downtime.

Concluding Noted!

CNC machining continues to improve manufacturing operations with superior accuracy, automation, and efficiency. From prototype making to high production, it validates high quality with minimum waste. However, selecting the right CNC machine is utmost. It usually depends on your production requirement, like geometry, quantity, and material type. As technology upgrades, AI and hybrid systems are evolving CNC machining.

For affordable and high-end quality products or custom designs, contact Premium Parts. Our experienced professional brings years of experience that will help you reach your desired machining outcomes. Visit our site to get instant solutions.

FAQs

Q1: What is CNC machining?

CNC Machining uses computer-assisted tools to shape, cut, and mill parts.

Q2: How accurate are CNC machines?

These machines produce parts with high precision levels, which stay within a 0.001-inch range.

Q3: What types of materials can CNC machines handle?

They process metal, plastic, and composite materials and also work with ceramic materials.

Q4: What criteria help me select the best CNC machine?

Decide on the machine features based on what material you work with and how precise your needs are. Also, evaluate speed and manufacturing capacity.

Q5: How does AI improve CNC production processes?

AI helps machines find better cutting routes while predicting machine health and making operations automatic.