Today, it is impossible to imagine the world of precision manufacturing without CNC (Computer Numerical Control) milling machines. It has become the go-to process in manufacturing due to its ability to manufacture complex parts with high precision, hence the name computer numerical control milling. The following is an elaborate guide with regard to the various parts of a CNC milling machine and the roles they play in achieving precision in operation. Whether you are engaged in CNC milling services or considering CNC custom parts manufacturing, it is vital to understand these parts to get the best out of the machine.

Understanding CNC Milling Machine Parts

All components of a CNC mill have their unique functions that enhance the machining performance, precision, and flexibility of the machine. If each component of the CNC milling machines is considered, then it becomes quite easy to understand the intricacies and technicalities associated with CNC milling.

1. Machine Bed

Vertical Milling Machine Bed

Image Description: A close-up view of a vertical milling machine bed showing its smooth metal surface and precision layout.

The machine bed is a supporting framework of the CNC milling machine; it bears the loads of the whole structure. Usually consisting of cast iron or steel, the machine bed absorbs forces and provides rigidity, both of which are paramount to achieving high accuracy in CNC milling. This strong foundation ensures that CNC milling services remain precise and avoid unnecessary motion or errors during the machining process.

2. Column

The main column is situated vertically on the machine bed, which can contain the spindle and control the modes of work. This structural element is very important for CNC milling since it carries the main motor and many other components. In CNC custom parts manufacturing, a strong column is an aspect of the machine that may determine the machine’s ability to handle tough jobs in part manufacturing.

3. Control Panel

CNC Milling Control Panel

CNC Milling Control Panel

Image Description: A CNC milling control panel with buttons, switches, and a display screen used to operate the machine.

The Control panel, sometimes known as the heart and brain of the CNC machine, is where all instructions are input and control of the machine is initiated. Here, operators enter commands that include speed, feed rate, and depth of cutting. The control panel deciphers these commands to understand the required movements and actions that lead the CNC milling machine parts to produce the specified component.

4. Spindle

Milling Machine Spindle

Milling Machine Spindle

Image Description: A close-up view of a milling machine spindle showing the rotating tool holder and metal surface.

The spindle is one of the most important components of any CNC milling machine. It supports and revolves around the cutting tool at very high speeds with a view to cutting and molding the workpiece. Spindles in CNC milling machines come in different powers and speeds, thus the capacity to work with different forms of materials. Premium Parts Manufacturing Limited particularly focuses on the aspects of spindles in computations for CNC milling because of their critical role in determining the precision and speed of the process.

5. Cutting Tool

Blades are available in many forms, and their purpose is to create certain impressions on the material being worked on. Carbide, high-speed steel, or even diamond-tipped materials make up these tools since they excel at material removal. When it comes to CNC custom parts manufacturing, the cutting tool selection must be done accurately to avoid poor surface finishes and loose tolerances.

6. Work Table

The work table is the part of the miller on which the workpiece is mounted when milling is in progress. Normally coupled with fixtures and clamps, the work table is also movable in the X, Y, and Z axes so that the cutting tool can access every corner of the workpiece. This level of movement and adaptability makes complex machining possible, and that is why parts of a CNC mill, such as the work table, are accurately made.

7. Saddle and Knee

The movements of the work table in the up and down and from side to side are controlled by the saddle and the knee. The saddle is positioned on the knee, and the table rests on it; the saddle may move along the length of the table, while the knee provides the opportunity for the table to move up and down. This combination is critical in the parts of a CNC mill, as it increases the versatility and maneuverability of the machine for deeper cutting and detailing.

8. Tool Changer

Most new generations of CNC milling machines include an ATC system that enables the machine to change tools without the need for operator intervention. This is especially helpful in CNC milling services operations that may involve the use of several tools in the same but different parts. The ATC enhances efficiency, reduces time wastage, and guarantees an uninterrupted flow of the machining operations, translating to shorter times to complete a given job and cutting costs.

9. Coolant System

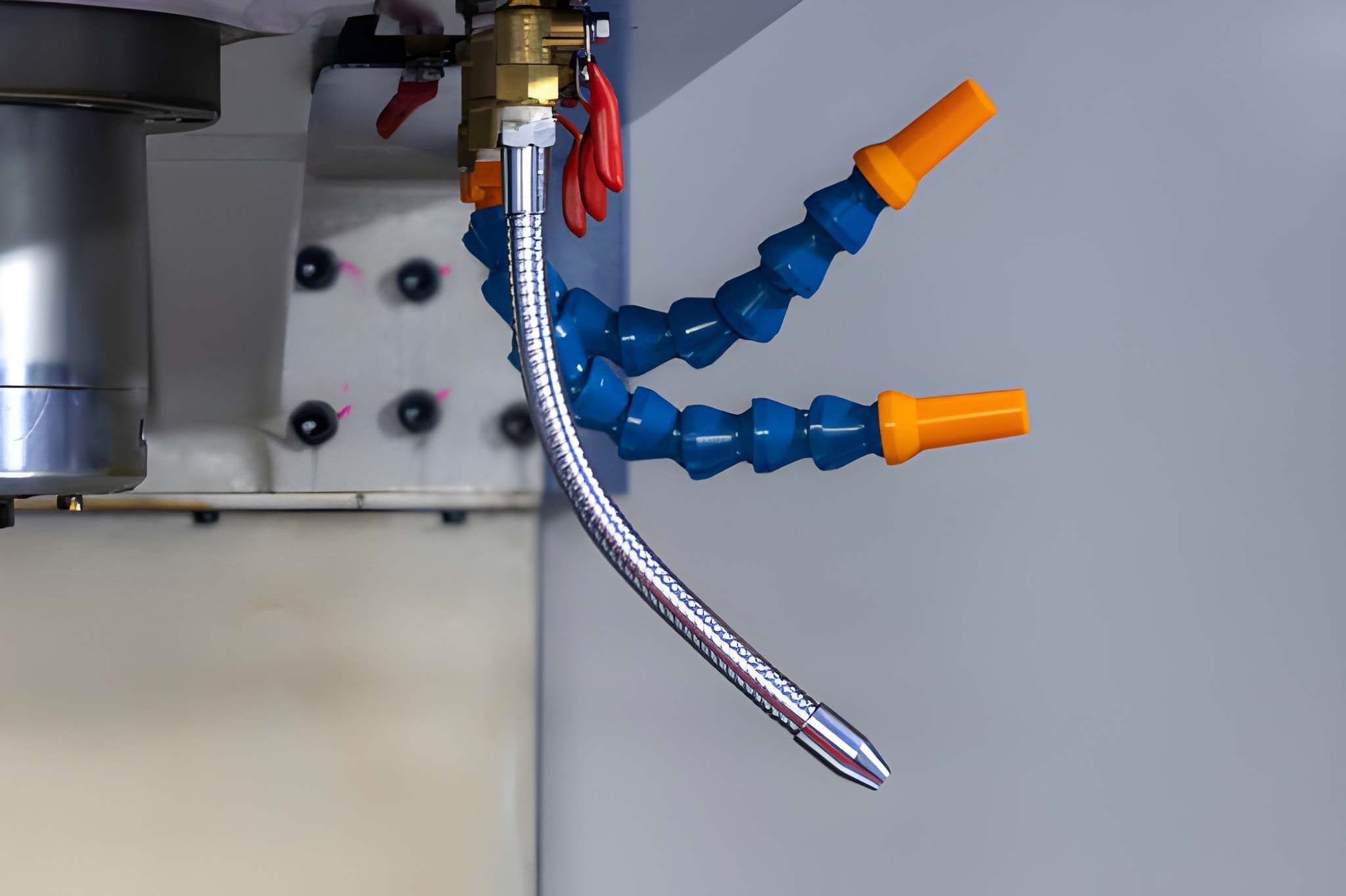

CNC Coolant Nozzle

CNC Coolant Nozzle

Image Description: A CNC coolant nozzle with a small adjustable metal tip.

The coolant system helps to cool the cutting tool and workpiece during milling to ensure that they do not get overly heated, which might cause damage to the tool or workpiece or both. Coolant is usually released through nozzles to provide accurate distribution in the cutting area, save on the tool, and improve cutting efficiency. Premium Parts Manufacturing Limited uses efficient coolant systems on its CNC milling machines to ensure high accuracy and to reduce wear of important CNC Milling Machine Parts.

10. Chip Management System

The problem associated with milling is that it generates metal shavings or chips, which are undesirable when present on the machine table. The chip management system takes away the chips from this cutting area to avoid hindrances and to create tidiness. Effective chip management is critical in CNC custom parts manufacturing since it facilitates the effective execution of the manufacturing processes.

Conclusion

An overview of the operations of various parts of a CNC milling machine will help you fully appreciate the working of these useful machines. Companies looking for a CNC milling service provider will be glad to work with Premium Parts Manufacturing Limited due to a combination of advanced technology and experience in the industry.

CNC milling is the most effective solution when it comes to quality, speed, and cost when the correct parts of the CNC milling machine and an appropriate supplier are in place. Are you seeking an experienced CNC Milling Services provider that can help you convert your designs into quality, precision-machined parts? If yes, then take advantage of working with Premium Parts Manufacturing Limited.