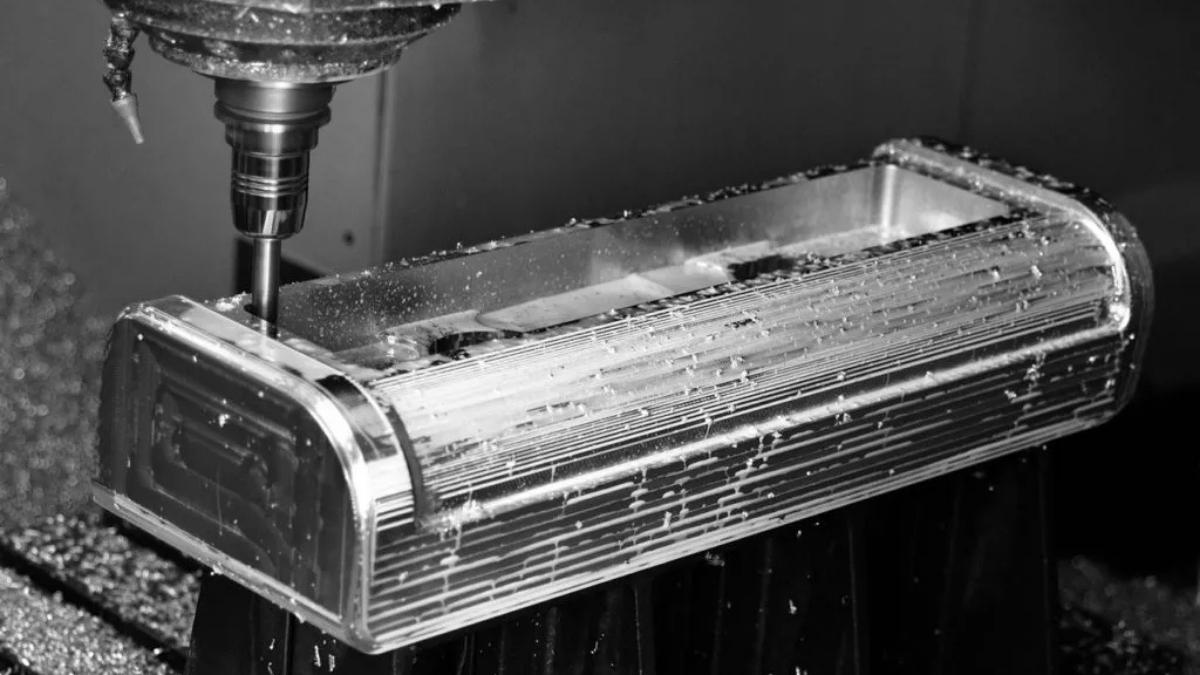

Robotic CNC Machining

Robotic CNC Machining

Image Description: The image shows a robotic arm handling metal parts during CNC machining. It highlights automation in the manufacturing process.

Unless you work with machines or make things for a living, you probably don’t think much about CNC machines. But the truth is that CNC machining is everywhere. It’s behind the phone cases in your hand. The car you drive. Even the life-saving medical equipment in hospitals.

CNC machines are the quiet powerhouses. These are shaping the world around us. They cut, mill, drill, and carve raw materials into super-precise parts, often down to a fraction of a millimeter. But what’s cool is how CNC machining applications stretch across so many industries.

Whether you’re a product designer, an engineer, a startup founder, or someone who just likes to know how things are made, this post will give you the full scoop on the various applications of CNC machines. We’ll walk through 10 major industries that use CNC machines, what they make with them, and the practical advantages of CNC machines in each case.

You’ll walk away knowing:

- The top industries that use CNC machines

- The most common CNC machine uses and advantages

- How to match your product needs with the right CNC machining application

- And whether this tech can give your project or business a margin

Let’s begin.

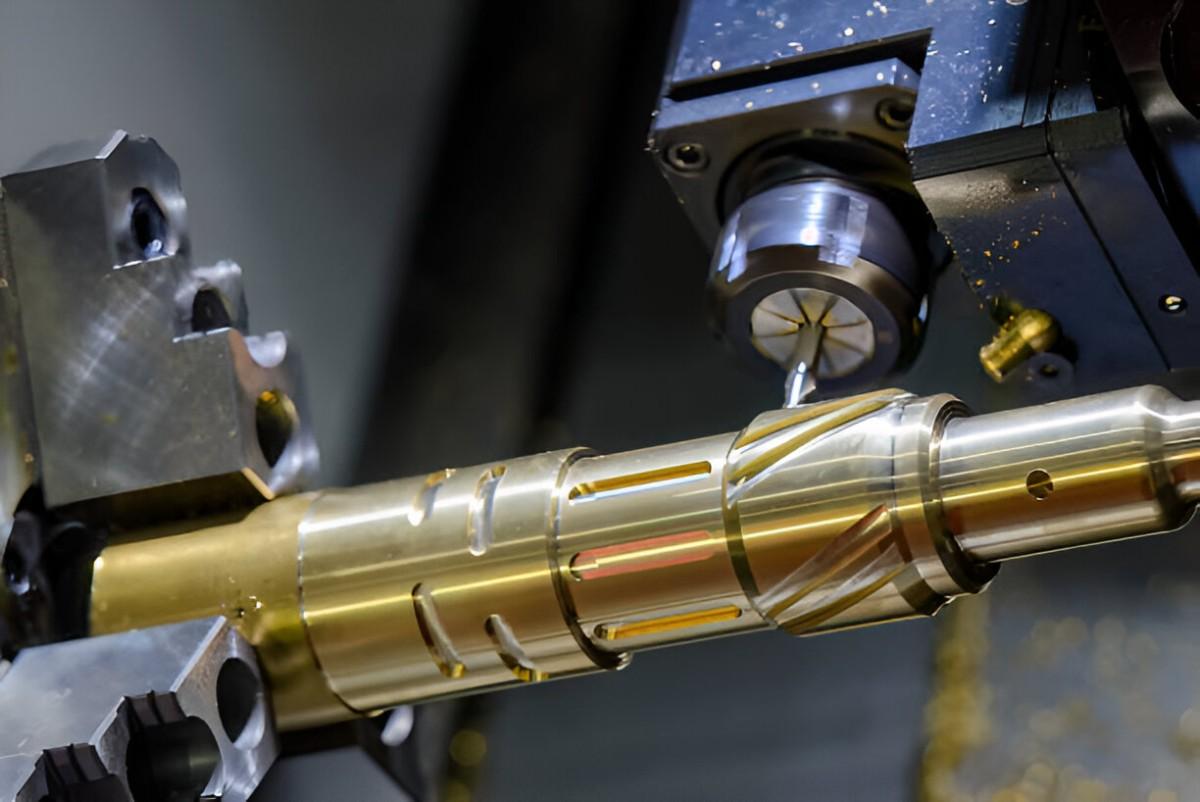

1. Automotive Industry

CNC Machined Shaft For Automotive

CNC Machined Shaft For Automotive

Image Description: The image is a close-up of a CNC-machined shaft for automotive use.

If you’ve ever driven a car that runs smoothly, shifts cleanly, and doesn’t fall apart when you hit a pothole, it probably owes a lot to CNC machines.

The automotive industry is one of the biggest users of CNC technology. From engine blocks to gearboxes to dashboard components, CNC machining helps bring car parts to life with speed, precision, and consistency.

Major CNC machines used in the auto industry:

- Engine and transmission components

- Suspension systems

- Lighting and dashboard parts

- Exhaust systems

- Custom car mods

Prototyping car parts: Auto companies use CNC to quickly test new ideas for parts and designs.

Making metal engine components: These include cylinder heads, pistons, and crankshafts. CNC machines cut them all with extremely high accuracy.

Creating custom or performance parts: Car modders and performance shops use CNC to machine custom brakes, suspension parts, and more.

And it’s not just about performance, it’s about safety too. CNC machining ensures that critical components meet tight tolerances, so drivers stay safe on the road.

In an industry that lives on speed and quality, CNC machines offer a perfect deal of fast turnaround, repeatability, and minimal waste. No wonder the auto giants (and even small tuning shops) swear by it.

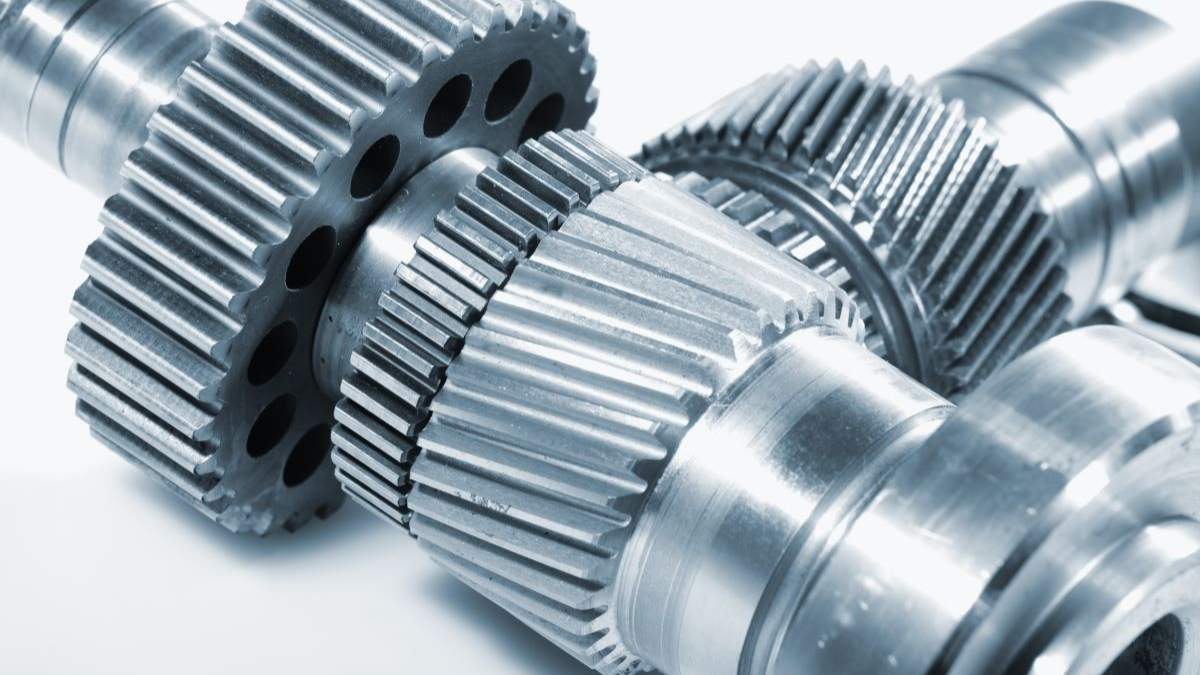

2. Aerospace Industry

Image Description: The image shows aerospace gear components made by CNC machining.

When it comes to flying at 35,000 feet, you don’t want to mess around with part quality. One tiny error in a jet engine component can be the difference between a smooth flight and a serious emergency.

That’s why the aerospace industry is super cautious, and CNC machining is up to the challenge.

Common CNC parts in aerospace:

- Turbine blades

- Wing ribs

- Landing gear components

- Control panels

- Fuel system parts

Here’s how CNC machines are used in aerospace:

- Machining structural parts: CNC is used to create complex, lightweight components for wings, fuselages, and landing gear.

- Making turbine blades and engine housings: These need extreme precision, especially with heat-resistant materials like titanium and Inconel.

- Tooling and jigs: Even the tools used to build airplanes are often CNC-machined.

This is one of the industries that use CNC machines, where CNC machines are not as a help but irreplaceable assets. Aircraft components need to be reliable under high stress, high temperatures, and zero room for error.

The big advantage here is that CNC machining allows aerospace companies to machine high-grade metals into detailed parts, keep everything within tight tolerances, and eliminate any room for guesswork.

3. Medical & Healthcare Industry

Image Description: The image shows medical parts made using CNC machining. It highlights the precision and detail of the components.

You probably wouldn’t expect CNC machines to play a role in healthcare, right? But they do, big time. From prosthetics to implants to surgical tools, the medical industry depends on CNC machining to create parts that need to fit perfectly, function flawlessly, and meet strict hygiene standards.

CNC machine uses and advantages in medical:

- Surgical instruments

- Joint replacements

- Dental prosthetics

- Custom braces and orthotics

- Diagnostic device components

What kind of medical parts are made using CNC Machining?

- Custom implants and joint replacements: CNC helps create titanium or ceramic implants customized according to each patient.

- Surgical tools: Scalpels, clamps, forceps, etc. All are machined to be smooth, clean, and consistent.

- Diagnostic equipment components: This includes the frames, arms, and supports for MRI and X-ray machines.

CNC machining can produce medical parts made with tough materials like stainless steel, titanium, or specialized plastics. With the increase in personalized medicine and custom prosthetics, CNC is a must.

The good thing is that CNC lets you machine single or small-batch parts without compromising on quality. It’s fast, accurate, and meets the high standards the healthcare industry demands.

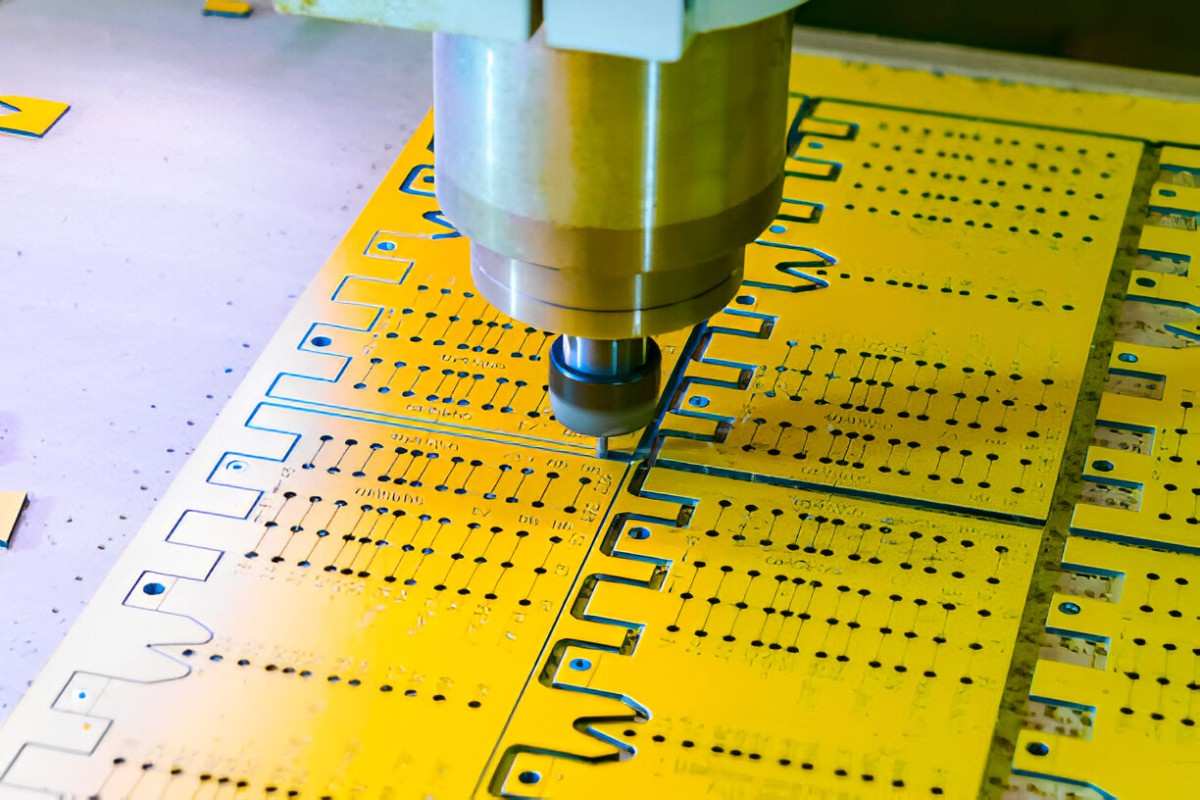

4. Consumer Electronics Industry

PCB Machining

PCB Machining

Image Description: The image shows a PCB board made using CNC machining.

This involves the regular items on your wrist and sitting on your desk. We’re talking about smartphones, laptops, tablets, wearables, and all those advanced gadgets.

Have you thought about how those aluminum MacBook shells or smartwatch casings get that smooth, clean finish? That’s CNC magic at work.

CNC machines are used in consumer tech:

- Machining aluminum and plastic enclosures: We’re talking about phone bodies, laptop frames, and camera housings.

- Making internal parts: Tiny brackets, heat sinks, and connectors all come from CNC machines.

- Creating prototypes for new devices: CNC is a go-to for design teams testing out the feel and function of new hardware.

When you’re designing something that has to look amazing and work flawlessly, CNC delivers. It gives tech brands the flexibility to iterate quickly, test different materials, and make super-sleek products with a luxury finish.

For this industry, both looks and performance matter alike. CNC machining offers unbeatable precision and aesthetics.

5. Defense & Military Industry

CNC Machining In the Defense Industry

CNC Machining In the Defense Industry

Image Description: The image shows a metal part being CNC machined for use in the defense industry.

When it comes to national defense, perfection is non-negotiable. A small defect in a weapon system, vehicle component, or communication device can lead to massive consequences. That’s exactly why it is one of the industries that uses CNC machines, because of their accurate results.

CNC Machining applications in defense:

- Firearm components

- Vehicle parts

- Surveillance equipment

- Protective gear mounts

- Tactical drones

CNC machines are used in creating defense:

- Weapon components: Barrels, firing pins, scopes, and mounts are often machined to meet exact specs.

- Aircraft parts: Just like in aerospace, CNC makes high-performance structural parts for military aircraft.

- Communication gear: Casings and mounts for radios, satellite systems, and tactical equipment.

Military applications often involve tough materials like titanium, hardened steel, or specialty alloys. CNC machines can handle those without any challenge.

Using CNC machining allows fast production of prototypes and limited-run parts. This is perfect for special missions or field repairs. That’s a huge CNC machining advantage in a world where speed can ideally save lives.

6. Marine & Shipbuilding Industry

Marine CNC Machining

Marine CNC Machining

Image Description: A detailed metal part being CNC machined for marine use.

All those massive ships, submarines, and marine engines are not simply built by welding and bolts. Many parts are machined using CNC, from tiny engine valves to huge propeller shafts.

CNC uses in marine manufacturing:

- Engine and gearbox components: CNC machines handle the intense endurance these high-powered systems need.

- Propellers and shafts: Large parts made from corrosion-resistant materials are shaped with CNC tech.

- Navigation system parts: Casings, brackets, and mounts for radar and sonar gear can be precisely machined with accuracy.

Saltwater environments are harsh, so parts need to be extremely durable and corrosion-resistant. CNC machines are great for cutting bronze, stainless steel, or composite plastics that stand up to the elements.

Key takeaway: In the marine world, it’s not just about size, it’s about reliability. CNC machines help build components that won’t crack under pressure (or 20,000 feet under the sea).

7. Energy Industry (Oil, Gas, Solar & Wind)

CNC Turbine Machining

CNC Turbine Machining

Image Description: The image shows CNC machining of turbine shafts and blades for the energy sector.

The energy sector might not seem flashy, but it’s full of tech, and CNC machines play a surprisingly big role in it. The energy companies rely on custom, rugged, and precise components during drilling for oil, harnessing wind power, or setting up solar panels.

Here are the common CNC machining uses in the energy sector:

- Oil & gas equipment: CNC creates valve parts, drill heads, and pipeline connectors that work deep underground.

- Wind turbine parts: Blades, gear systems, and rotor components need high strength and perfect balance.

- Solar system brackets: Solar farms use tons of CNC-made aluminum frames and mounts.

Energy equipment works in tough environments like extreme heat, cold, pressure, and vibration. CNC machining delivers parts that can handle all that without failing.

This matters because the downtime is very expensive in energy. With CNC, companies get consistent parts that last longer, work better, and reduce maintenance costs.

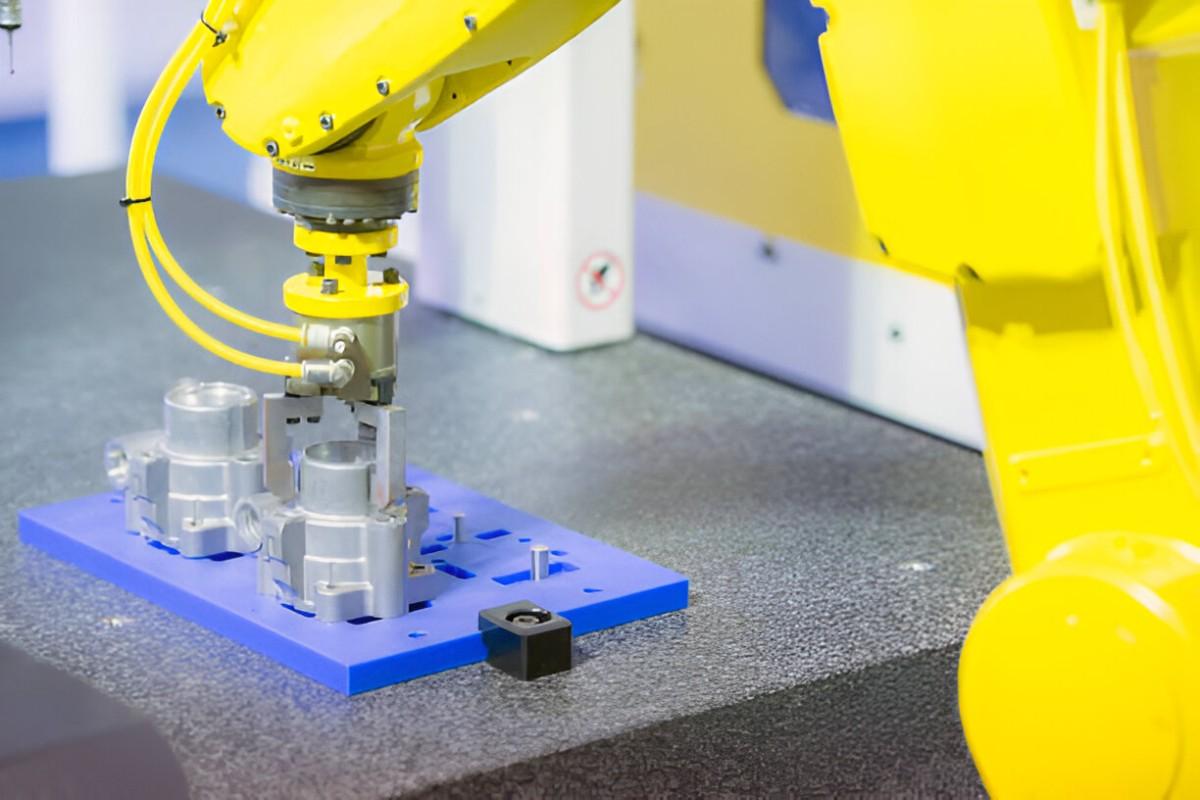

8. Robotics & Automation

CNC Machining In the Robotics Industry

CNC Machining In the Robotics Industry

Image Description: A showcase of a robotic system performing CNC machining by picking and handling parts

Robotics is one of the big industries where CNC plays an important role. You see them in factories, warehouses, hospitals, and now even homes. Every moving part of a robot has to be made right. This means no loose gears and no shaky joints. That’s where CNC machining blooms.

CNC machines are used in robotics:

- Robot arm components: Joints, gearboxes, and grippers are all made with tight tolerances.

- Frame and body parts: CNC cuts clean aluminum frames that are lightweight and durable.

- Prototyping custom bots: Startup businesses use CNC to test new robotic systems quickly.

Robotics requires both strength and accuracy. You want a strong and smooth robot to do its job, without knocking things over. CNC helps engineers achieve that ideal spot.

Fun fact: CNC machines are sometimes used to build other CNC machines and robots. It’s the circle of manufacturing life.

9. Furniture & Interior Design

CNC Woodworking

CNC Woodworking

Image Description: The image shows a CNC routing machine carving patterns into wood.

This one surprises people, but it’s a fact that CNC machines are making their way into custom furniture and modern interiors. No more mass-produced, cookie-cutter tables. Designers now use CNC machining to bring creative, one-of-a-kind pieces to life.

CNC applications in home and office spaces:

- Custom furniture: Chairs, tables, and bed frames are cut with CNC for perfect joints and sleek designs.

- Architectural panels: CNC routers carve out patterns in wood or plastic for walls and ceilings.

- Kitchen and bathroom hardware: Faucets, handles, and fixtures made from stainless steel or brass.

Interior designers love CNC because it offers quality and creativity. You can repeat a design across multiple pieces, or experiment with curves and angles you’d never get by hand. CNC is a utility with beauty. Especially when your home or office is the canvas.

10. Fashion & Accessories

CNC Machining Accessories

CNC Machining Accessories

Image Description: The image shows a CNC-machined automotive accessory.

Finally, the most talked-about fashion world. You wouldn’t think runway looks or luxury accessories had anything to do with CNC machines. But designers and makers are using them more than ever.

CNC machining in the fashion world:

- Jewelry making: CNC machines shape gold, silver, and platinum for rings, necklaces, and custom pieces.

- Eyewear: CNC cuts perfect curves in acetate or metal for stylish, wearable frames.

- Footwear molds: Shoe soles are prototyped using CNC tools to get the fit and feel just right.

High-end fashion brands are starting to mix tech with tradition, and CNC gives them the tools to do it. The clean lines, sleek cuts, and repeatable perfection are all done via CNC without stepping back from creativity.

The reason CNC is used in this area is simple. Brands want things to be unique and precise. CNC makes that possible, especially for limited runs and high-value pieces.

Conclusion

So here we can wrap it all up. 10 industries that use CNC machines every single day to make things faster, better, and more cost-effective. CNC machining is one of those rare technologies that crosses nearly every industry imaginable. Cars, planes, phones, medical gear, robots, or even fashion accessories, CNC machines are there for sure.

So if you’ve ever wondered about the various CNC machining applications or thought about using CNC for your project, now you know just how versatile it is.

And here’s the plus: you don’t need to be a big-name company to get high-quality CNC parts. That’s where we come in.

At Premium Parts, we specialize in rapid prototyping and low-volume CNC machining for customers all around the world. From one-off prototypes to small production runs, we make custom parts that work every time.

With a team of engineers that’s been doing this for 15+ years, we’ve seen it all. Automotive, aerospace, medical, electronics—you name it. We deliver fast, precise, and reliable machining services so your ideas can actually turn into real products. Reach out to us and let’s make designs come true. Visit Premium Parts to Get a Free Quote Now!