CNC Milling Machine with Panel

CNC Milling Machine with Panel

Image Description: Modern CNC panel machine with a snap-on background, showing an open section of the working area.

There’s no overstating the importance of selecting the best manufacturer and supplier for all kinds of businesses. For retailers, having the right supplier can mean a sizeable profit margin, liquidity, credit period, and more. Getting it wrong can equally result in bad sales, high costs, and low profit. For CEOs, Product Designers, and Businesses, the risks and rewards are even higher – Brand popularity, customer loyalty, market share, franchises, and profit could be gained or lost depending on the quality of the product, its durability, finish, market price, and landing cost. To gain a competitive edge from the start, having a reliable manufacturer is one of the most important factors to secure.

When picking a manufacturing outlet, price is often at the top of the considerations. And while pricing is one of the factors to be considered, it is not the right place to start. Today, businesses need to select the right CNC shop and look beyond pricing to avoid more costly mistakes down the line. To decide what machining option to work with, we have put together a few considerations to help you make the right choice.

Considerations When Choosing a CNC Machining Shop in China

Key Factors for Choosing a CNC Shop

Key Factors for Choosing a CNC Shop

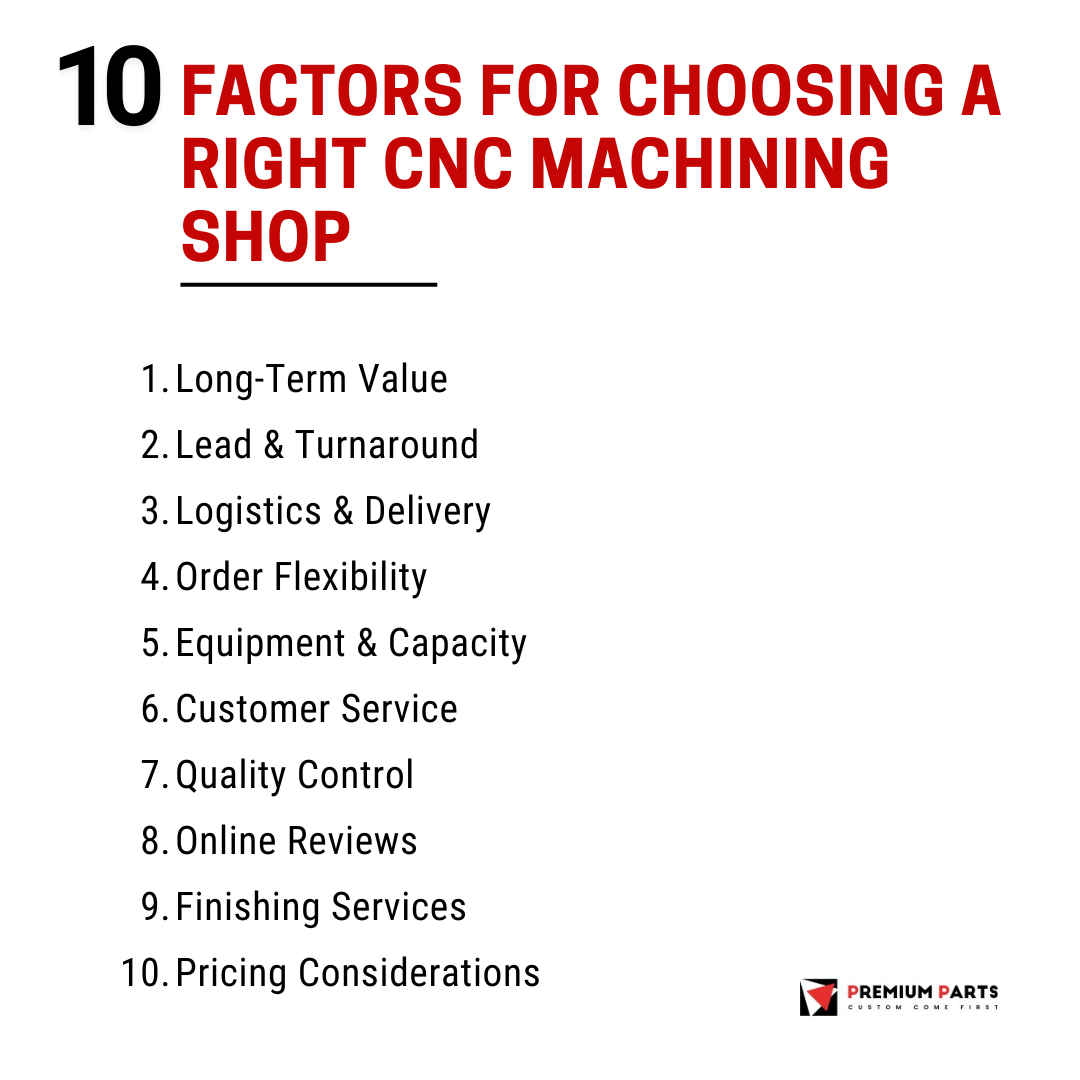

Image Description: An infographic listing 10 Key Factors for Choosing a reliable CNC Shop.

Choosing the right CNC machining shop is important for your project’s success. Considering the right factors ensures quality, reliability, and production efficiency. The following points will help you make the best decision.

1. Look for Long-term value

When searching for the best CNC machining shop in China, the best place to start is by seeking value. Having a firm understanding of each manufacturer’s value proposition and how it keys into your project is essential. Is the machining shop purely motivated by money? Is it a standout characteristic quality? Once you’ve gotten your answer, the next step is to evaluate these values and see if they align with what your business needs. It goes without saying that the value you get from a highly refined CNC shop far surpasses the money paid for such services.

It is important to remember that the value you get from your manufacturer has a long-term effect on the type of product you manufacture. More often than not, cheap prices will consequently produce cheap jobs. Having perfect orders that will proudly carry your brand is a better investment than cheap products that can damage the reputation of your business with potential customers.

2. Lead and Turnaround Times

Even global consumer brands like Microsoft, Sony, Apple, Google, and Samsung all acknowledge the importance of early market entry and pioneering technology. Lead times are very crucial in manufacturing as they can often be the difference between the market success of one product over the other. As the manufacturing climate gets more competitive, there is no downplaying the advantage that being first in the market brings. Year after year, the Apple iPhone and Samsung Galaxy and Note smartphones all battle it out, setting ambitious release dates to outdo one another. Even the recently announced Sony PlayStation 5 is to be fiercely rivaled by the Microsoft Xbox One X Series, as both consoles are set to hit the market in November.

The right machining shop for you can meet your deadlines well before the due date, allowing you to test the market and enter before your competition.

There’s no overstating the importance of selecting the best manufacturer and supplier for all kinds of businesses. For retailers, having the right supplier can mean a sizeable profit margin

3. Consider logistics

Logistics is the backbone of every supply chain. Consider factors like nearness to market, availability of raw materials in the supplier area, the road networks, the ease of transportation, the presence of an online manufacturing-as-a-service platform, shipping, and delivery before choosing your CNC machining shop.

The ideal machining shop should be exact with its logistics, having a strong network of suppliers that can meet your project raw material demands. You should also consider businesses in established or industrial areas to prevent damage to your finished products due to poor road networks. The nearness of your machinist to the market can also help you avoid transportation costs that will be passed onto the price per unit produced.

The most essential part of logistics is the ease of delivery; as the internet continues to boom, many businesses are conducted without the need for physical presence. Ensure that the machinist shop you choose can handle raw material supply, guarantee safe shipping, and offer affordable delivery costs.

4. Production Order Flexibility

Due to the high costs of operation and maintenance, most CNC shops require a minimum order quantity (MOQ). This quantity is the lowest quantity the shop is willing to quote prices and run production.

The right machining shop has no fixed MOQ, as this number should vary depending on the material, volume, price per part, and delivery times. When selecting a CNC manufacturer for your business, ensure that they offer services in low-volume manufacturing, prototyping, and bridge production.

5. Equipment and Capacity

Your ideal CNC machining shop should have a reasonable in-house capacity and be equipped with the best-in-line technologies for optimal production.

Before proceeding with a manufacturer, inquire about what volumes and units they can produce in a single run, the material options available, the labor strength, the skill and experience of the engineers, the type of CNC machines available, and turnaround times.

Machining shops with a limited capacity will often mean a long job queue, leaving your business to wait before your orders can be fulfilled. Poor in-house capabilities may also mean these small machining shops need to outsource for your job. IF this is the case, there is a likelihood of passing the cost onto you. There is also a risk that your innovation may be exposed outside their facility, putting competitors on alert.

6. Customer service matters

Poor customer service is a no-no for every business. Considering the complexities of manufacturing, one can anticipate some back and forth in communicating design, challenges encountered, the need for modifications, and even logistics.

Consider the availability of a dedicated customer service desk that can help you communicate your requirements clearly, keep you up to date on the production, and clearly articulate your complaints to the production team. Customer service is critical when your manufacturer is some distance from you, and walk-ins are not exactly seamless.

7. Quality Control Process

Many people see quality control as a process executed at the end of production. This could be no further from the truth. Quality control and assurance are process continuums that span the whole production process. For a high-quality machining shop, quality control begins with design. From the model, expert machinists will be able to identify potential defects and design issues that could impact the final product’s functionality.

Once the design has been settled, the material selection process follows. As is popular in computing, garbage-in equals garbage-out; your part supplier must understand how crucial it is to select the best material and articulate its properties for the final product to achieve success. When selecting the best CNC machining shop in China, ensure that you review their quality control process documentation. The ideal shop should be able to provide you with inspection certificates, testing results, and material certifications. You also want to work with a supplier that has the correct set of ISO certifications.

8. Check online reviews

Not all businesses have a strong online presence. If you, however, find the company’s website, look out for online reviews to see what customers are saying about them. You can also conduct a quick Google search to see praises, critiques, and areas of strength from independent parties that have run a project with your supplier in the past.

Your ideal machining shop need not have 5-star reviews, but they should not have anything lower than four stars. Also, read the reviews to identify areas where the shop is lacking and how this affects the overall delivery of your project.

9. Finishing Services

Look out for CNC machining shops that offer a full range of finishing services to help save time and cost. If your product is particular about visual appeal, aesthetic, finish, and surface texture, you want a supplier that can do all the required finishing in-house. Not only will this help you maintain the same quality from start to finish, but it can also help you save significant costs of transportation and logistics that may arise from moving your parts from one shop to another for finishing.

10. Pricing

Last on our list is the price. Although pricing is significant, it should not be the primary driving factor, as it often is. Before concluding on the machining shop for your CNC machining in China, consider lead times, quality, capacity, and long-term value. Once this supplier ticks the right boxes, request a quote and put it against other quotes. While the pricing affects the overall landing cost and price per unit of a product, remember that other qualitative factors matter.

Partner with Premium Parts for Precision Machining Solutions

Premium Parts offer complete CNC machining services, including milling, turning, and EDM, using a wide range of metals and plastics. From single prototypes to large production volumes, we handle every project with care. When you send us your design file, our engineers will meticulously review your design. We provide you with a free DFM review and offer suggestions on your design. This allows you to optimize your design and maximize production outcomes.

Our company adheres to ISO-certified quality assurance standards and ships parts with minimal turnaround times. Our multi-axis machines and experienced team make even complex parts simple to produce, giving you reliable, high-quality results every time.