The versatility of aluminum is well documented; from its lightweight to affordability, ease of machining, and environmental friendliness, aluminum has been successfully used in many industries. Industrial aluminum profiles refer to the aluminum material suitable for use as a main component in industrial aluminum extrusion processes.

In the extrusion process, the chosen aluminum bar is extruded by melting the material forced into a particular die with the desired section shape. The mechanical and functional properties of the finished product depend on the selected aluminum profile. What factors then make one aluminum profile more suitable than another? These seven factors and considerations are used to highlight the differences:

Strength

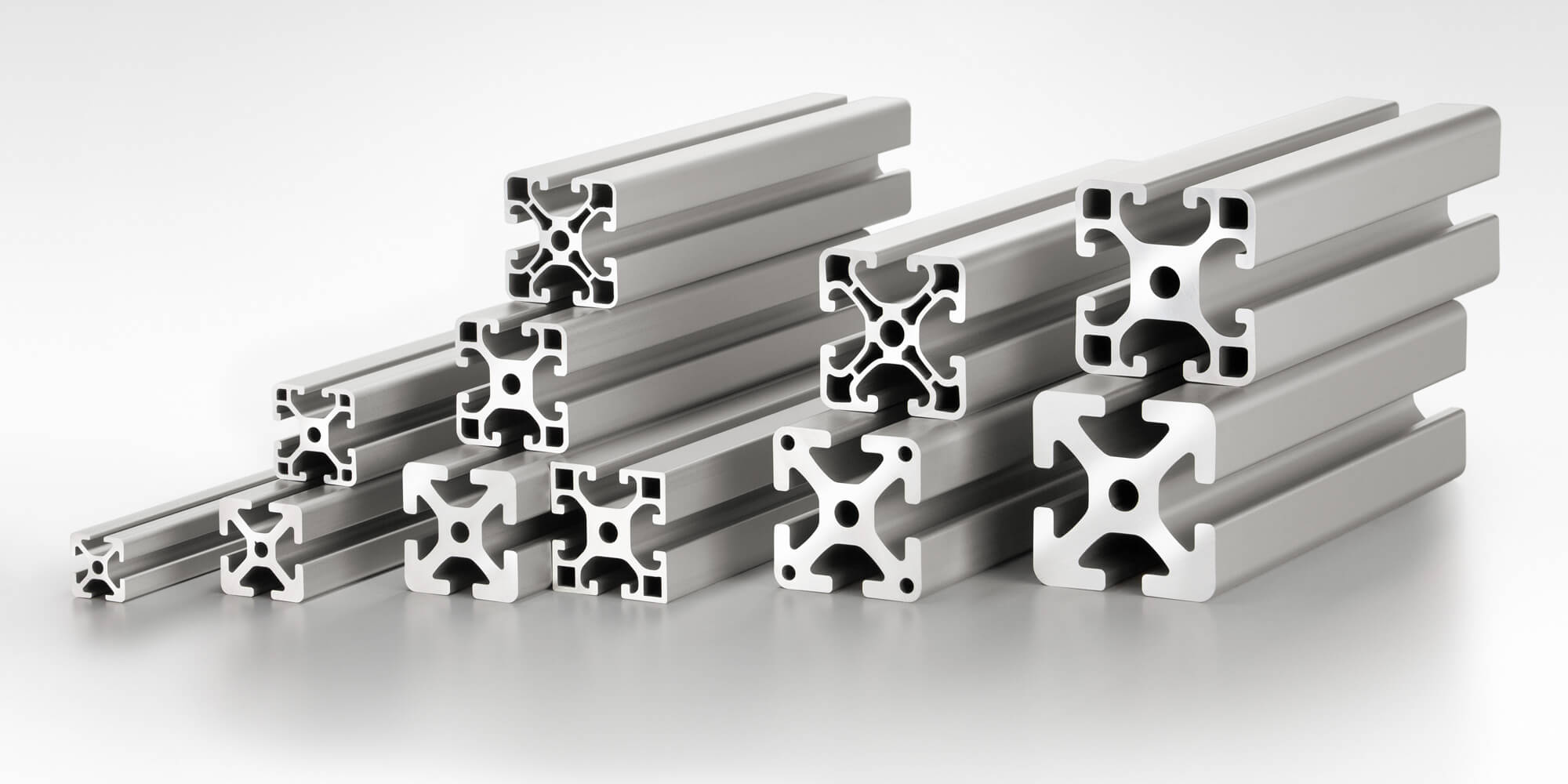

Aluminum Extrusion Profiles

Aluminum Extrusion Profiles

Image Description: Aluminum extrusion profiles, these are showing long, shaped aluminum pieces with smooth surfaces.

Strength or durability refers to the ability of the aluminum profile to withstand pressure, damage, wear, and tear that arise from the day-to-day use of the part as intended. It also refers to the ability of the part to withstand pressure and heat treatment. The maximum tensile strength is the amount of stretch or pulling the profile can take before its mechanical properties are permanently altered.

Generally, pure aluminum 1100 has the lowest strength, while the heat-treated alloy series of 2024 and 7075 are progressively higher in strength. The 5052 and 6061 offer medium to high mechanical strength.

Hardness

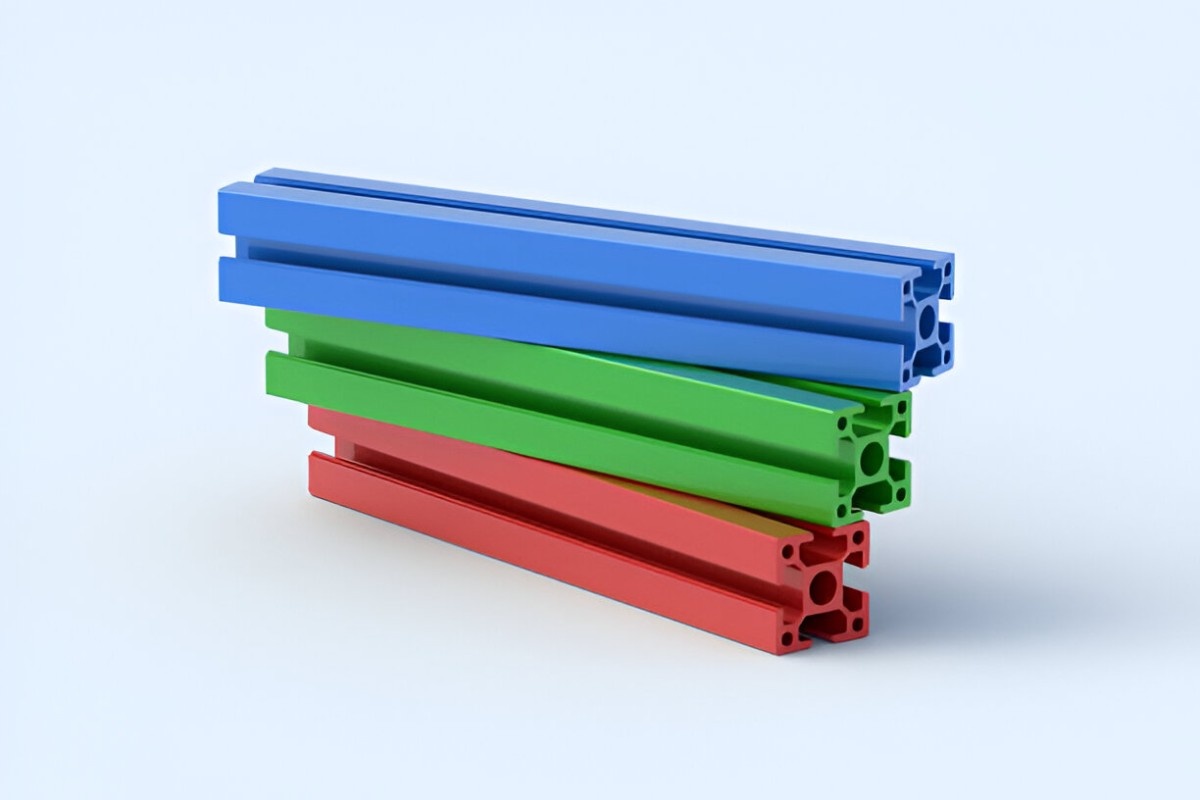

Aluminum Extrusion Profile of Vibrant Colors

Image Description: Aluminum extrusion profiles of vibrant colors. These are displayed on a table in different shapes and shades.

Hardness is different from the aluminum profile strength and is a factor in the aluminum profile’s chemical composition. The state of the aluminum profile also has a profound influence on the hardness of the profile. The hardness matrix decreases from 7 to 2,4,6,5,3, and 1 series in that order.

Corrosion Resistance

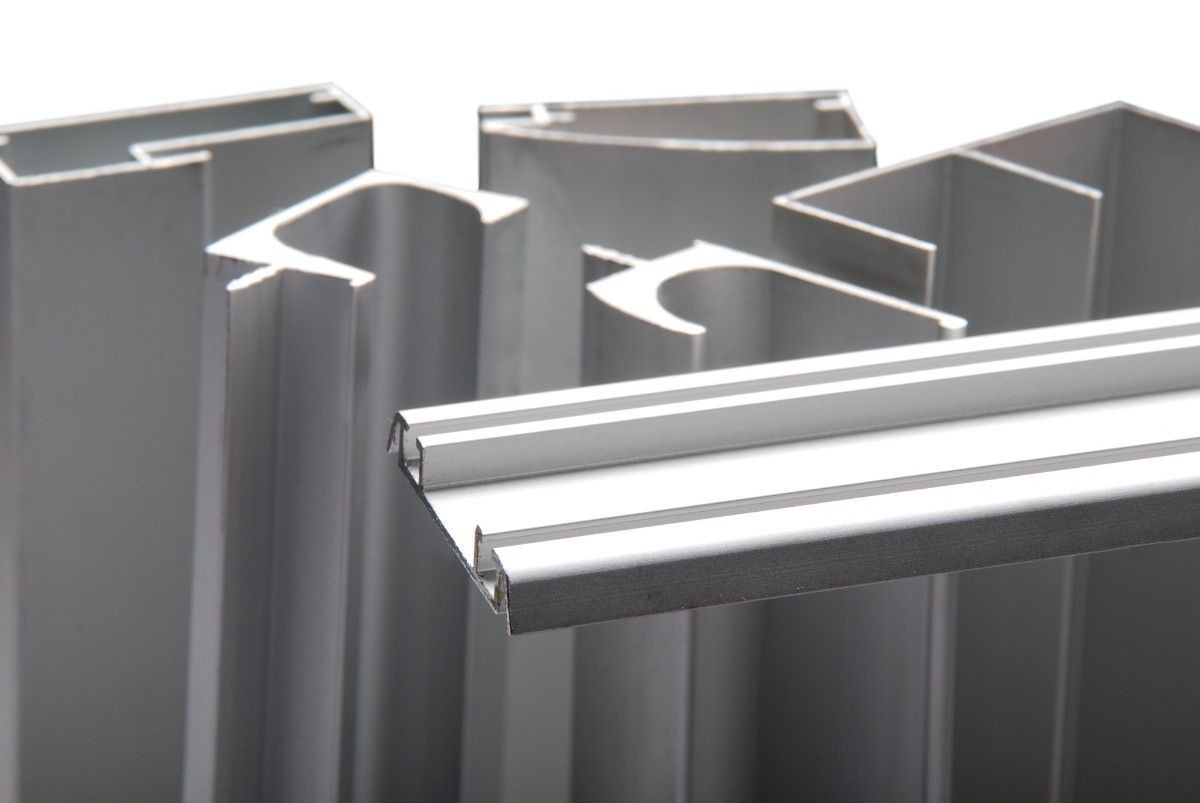

Stacked Aluminum Extrusion Profile

Stacked Aluminum Extrusion Profile

Image Description: Stacked aluminum extrusion profiles are shown placed one over another in a neat pile.

Corrosion resistance speaks to the ability of an aluminum profile to withstand the chemical changes to its structure arising from exposure to chemical and rust conditions.

In this case, the best corrosion resistance is seen in the 1 series. Next is the 5 series, then comes the 3, 6, 2, and 7 series in that order. In clearer terms, the Alloys 1100, 5052, and 6061 have excellent to very good mechanical properties, the 3003 and 6063 have decent corrosion resistance, while the 2 series is generally poor.

Weldability

Aluminum Extrusion Welding

Aluminum Extrusion Welding

Image Description: The image shows aluminum pieces being joined together by welding.

Weldability refers to how easily an aluminum profile can be welded. The weldability of most aluminum profiles is generally very good. However, profiles of alloys 2024, 7075, and 2011 are inferior. Alloys 3003 and 1100 have excellent welding performance. The 5 series of aluminum profiles are particularly designed for welding.

Machinability

Machinability performance entails the ease of forming and machining an aluminum profile. This includes cutting, forming, and turning in some instances. Generally, the machinability of each aluminum profile may be affected by heat treatment or annealing. Annealed parts are very machinable and formable, while heat-treated aluminum materials are more challenging to machine. The alloys of 2011 are excellent for machining, including the 1100, 3003, and 6061 alloys.

Finishing

Anodized Aluminum Extrusion Profiles

Anodized Aluminum Extrusion Profiles

Image Description: Anodized Aluminum Extrusion profiles with a smooth, colored surface finish for protection and appearance.

Aluminum profiles may be coated, anodized, polished, and more to obtain the desired feel, look, and finish. Depending on the end-use and environmental conditions where the part may be deployed, the aluminum profile for extrusion may need specific chemical and surface treatments to deliver on performance expectations.

End-use

By research and experience, certain aluminum profiles are more suitable for some industries than others. For instance, the Aluminium alloys 2011 and 1100 are broadly used in general machining and metal spinning, while the 2024 and 7075 are deployed in metal spinning and the aerospace industries, respectively.

Aluminum alloys 3003 are widely used to fabricate food and chemical equipment, while the 5052 alloys are applied in marine fabrications. Alloys 6063 and 6061 are best suited for structural (like heavy duty casters) and building material applications, such as tile trim.

Premium Parts Aluminum Extrusion Services In China

Premium Parts provides aluminum extrusion processing services for a wide array of applications in China. Our in-house capacity can deliver quality, avoid defects like burrs and flashes, and facilitate low-volume manufacturing at affordable rates. Our other portfolio of services covers 3D printing, urethane casting, injection molding, and CNC machining.

If aluminum extrusion is one of the services you’re looking to secure in manufacturing your parts, please get in touch with us to get a free quote from our expert engineers and design inspection to get started on your project.