CNC Prototyping helps businesses to get a real-time feel of the original product before actually going into mass production to save cost, time, and energy.

In today’s era, CNC machining has been widely used to create prototypes for various industries. Various digital models created by CAD experts are used for CNC prototyping to craft a perfect design before going into the mass production phase.

CNC machining is a subtractive process where precision tools create end products depending on industry demands. CNC prototyping is extremely useful to eradicate potential problems that might pop up during the manufacturing process. In case no one addresses these setbacks, then the result might not meet the expectations, inflicting huge time and financial losses.

In this article, we will take a closer look at rapid CNC prototyping to determine its usability for industries. Before that, let’s make a little sneak peek at CNC machining.

What is CNC Machining

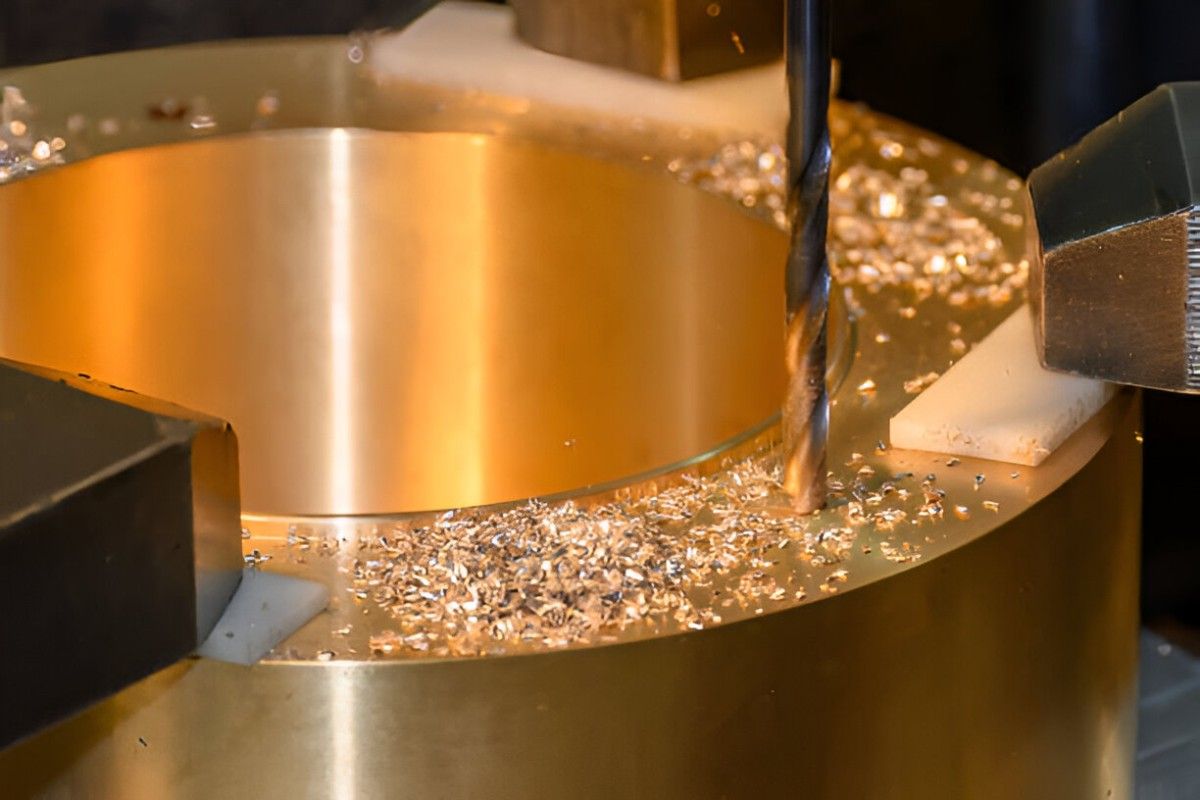

CNC Machining Bronze

CNC Machining Bronze

Image Description: A CNC machine drilling precise holes into a brass part.

CNC or Computer Numerical Control machining uses precision tools combined with computer-aided designs (CAD) to complete or facilitate manufacturing. The computer-controlled machining tools remove material from the workpiece to give it a final refined shape. There are two major types of CNC machining;

Milling Machine

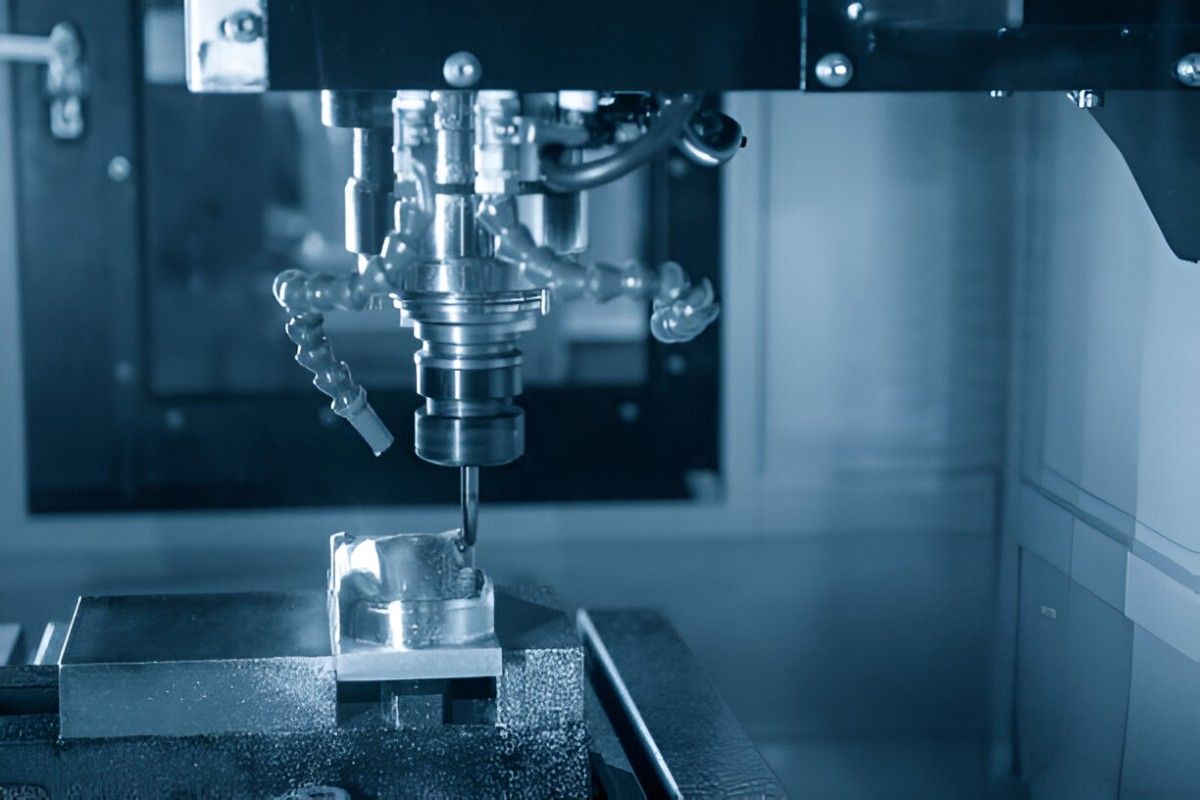

CNC Milling Machining

CNC Milling Machining

Image Description: A CNC Milling Machine making a tiny part.

Milling machines use rotary cutting tools staged on multiple axes to mill or remove materials from the workpieces to shape new materials.

Lathe Machines

Bronze Turned Parts

Bronze Turned Parts

Image Description: Precision-turned bronze parts produced on a CNC lathe machine.

Lathe machines rotate material against the lateral stationary cutting tools, which remove material from the piece to give it the desired geometry.

These CNC machines are used to create prototypes. Let’s now unveil what rapid CNC prototyping is and the multiple factors associated with it.

What is Rapid CNC Prototyping

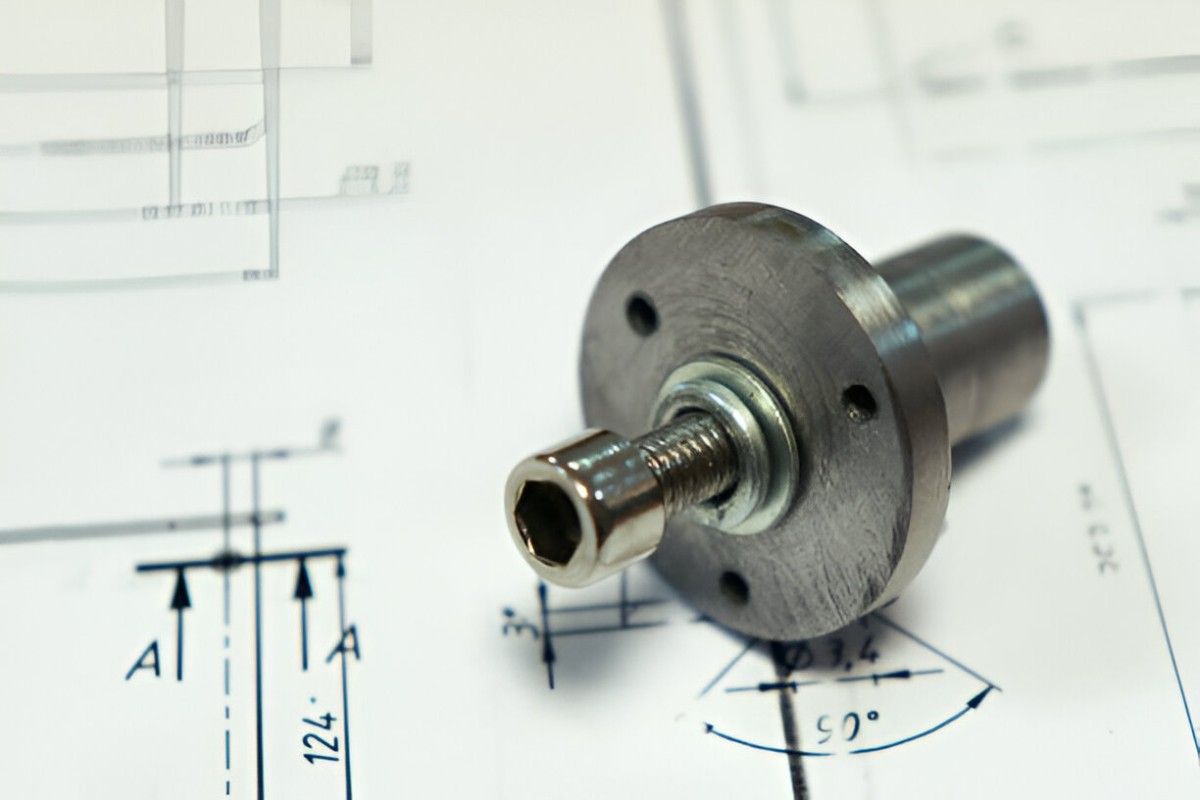

Mechanical Part on Drawing

Mechanical Part on Drawing

Image Description: A finished mechanical part placed on top of its technical engineering drawing.

CNC rapid prototyping is a widely coined term for creating prototypes using CNC machines. Basically, before going into mass production, industries seek prototypes to eradicate potential problems.

Then selected prototype, testing, or engineering sample is chosen for full-scale production. Rapid prototyping is generally divided into two categories;

The first category prototypes are generally used as models to get the proofs of concept or obtain a rough idea about the physical object that drives the R&D process. These are weaker models and can never be introduced to stresses or strains. 3D printing machines can make these prototypes.

The second category, prototypes or engineering prototypes, is precisely crafted to bear the stresses. These are actually designed to check the strength and other characteristics of the final product created afterward. These are the main specialties of CNC rapid prototyping machines.

Benefits of CNC Prototyping

The physical prototypes always have the upper hand over the digital ones in the following ways;

- Even the most unique and elegant design in CAD can’t serve the purpose of the physical object. Its importance reaches its pinnacle when business agreements are made, as partners always prioritize physical sampling instead of digital.

- The exceptional speed of creating these samples further emphasizes its importance. Additionally, efficient incorporation of feedback to reach the desired outcomes comes in handy with these prototypes.

- These prototypes facilitate researchers and engineers to explore concepts in a low-risk environment at a very low price.

All these factors help businesses and industries to minimize potential design flaws that could result in severe complications later on.

Advantages and Disadvantages of Rapid CNC Prototyping

There are hundreds of benefits associated with CNC prototyping. Let’s list a very few of them;

Advantages of Rapid CNC Prototyping

Rapid Production

With the CNC machining, the prototyping process has been a lot easier. CNC prototyping service providers claim to accomplish most of the tasks within a week. Premium Parts ensures top-notch quality at the fastest possible execution according to the scope of work.

Precision and Accuracy

CNC prototyping can precisely mill the desired shape within a fraction of a millimeter. The precision is up to the levels that testing these samples accurately reflects the concerned product. Even bulk product with CNC machining offers consistent outcomes.

Additionally, variations to any side can be made at any stage of the prototyping process without disturbing the other ones. This makes the incorporation of feedback extremely easy.

No Extra Tooling

Traditional methods usually require different and customized tools for every single prototype. This extends the prototyping process from weeks to several months, which is not a feasible option. With CNC prototyping, everything is pre-installed and ready. So, rapid CNC prototyping completes the process in a matter of a few days, depending upon the complexity of the prototype required.

Premium Parts ensure the completion of every CNC prototyping process at the earliest without compromising the quality.

Wide Range of Materials

A vast range of materials from aluminum to plastic, copper to stainless steel, and countless other options are available with CNC machining. In contrast, other methods like 3D printing lack diversity.

Premium Parts stocks aluminum, brass, bronze, zinc, urethane, plastic, steel, copper, and multiple other materials, considering their varying use in different industries.

Disadvantages of Rapid CNC Prototyping

Though this marvelous technology of CNC prototyping has countless benefits, there are a few downsides to it. Let’s take a closer look to determine whether these drawbacks are strong enough to look for alternatives or not.

1. Cost

Most people compare the cost of CNC prototyping with 3D printing. If that’s the case, then yes, CNC is expensive. But, if someone looks at the countless benefits associated with CNC prototyping, then that’s comparison looks worthless.

If you compare CNC prototyping with other physical prototype-making processes, CNC is way more cost-effective than any.

2. Geometric Limitations

CNC machines have a limited number of axes. Thus, highly complex prototyping might not achieve the desired precision and accuracy.

That might be the case with other CNC prototyping service providers, but Premium Parts has the most advanced machinery that can go to any extent to produce desired shapes. Though too complex prototyping is also possible with CNC, it’s an indication of how expensive and difficult it would turn out when someone opts for such intricate designs for mass production.

The Bottom Line

Designing and executing prototypes has never been so easy, but thanks to rapid CNC prototyping for precision, speed, and accuracy in the process.

Premium Parts is the best CNC prototyping service provider equipped with modern machinery, skilled workers, and top-notch professionals. From CNC milling to CNC lathe, everything is just unified under one roof. Premium Parts is your one-stop shop for every CNC-related need.

If you need CNC prototyping of any caliber, feel free to get in touch with us and get a quote now!