Undercut Machining

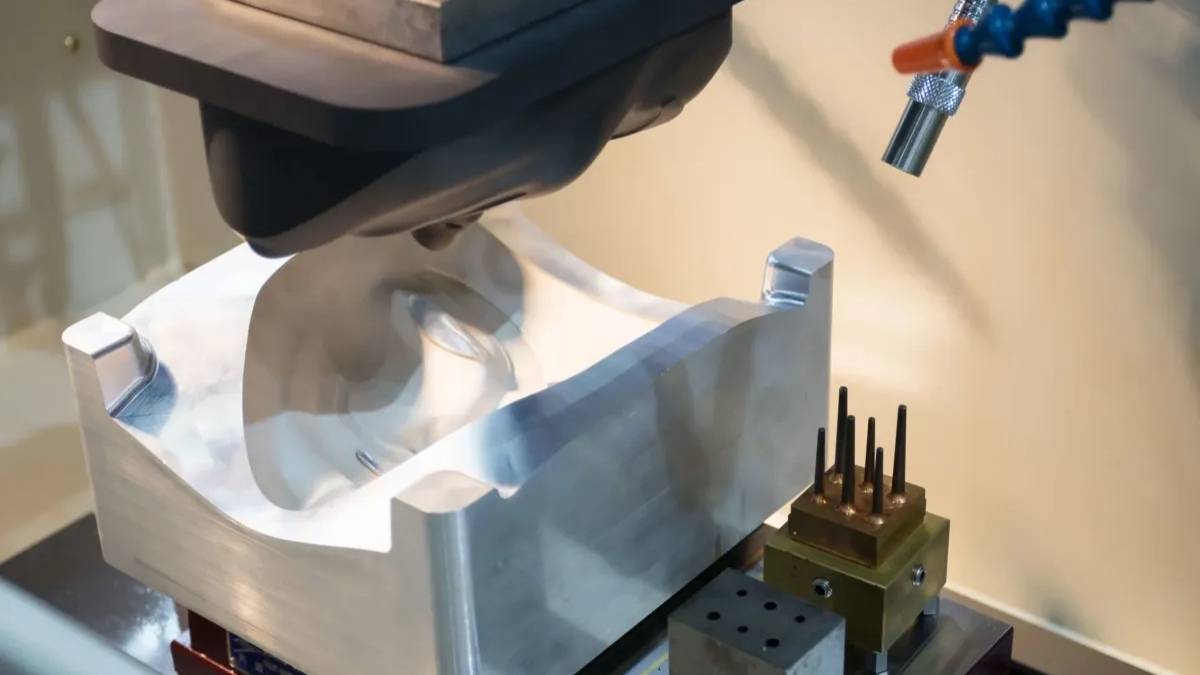

Image Description: The image shows a CNC machine performing undercut machining, where the tool cuts beneath the surface to create a recessed feature in the metal part.

Standard cutting tools have limits when it comes to performing complex manufacturing operations. The manufacturing process presents major challenges in making interlocking parts, designing molds, and creating keyways. The lack of suitable machining techniques and tools makes achieving the desired product quality problematic.

Undercut Machining is a critical part of precision engineering and plays a vital role. It features many challenges to cope with. So, simply said, you need to acquire expertise and careful negotiation to avoid it. Precision in undercuts is not an easy task. Especially when you are a beginner, aside from this, you need to employ the correct strategies and tools to achieve the desired results. Nowadays, the advanced multi-axis CNC machining control has made it possible to obtain precise undercuts. Nevertheless, manual approaches still hold significance in low volume.

Keep on reading as the article demonstrates undercut machining techniques, material and tool selection, and measures for high-end production outcomes. Additionally, we will compare CNC vs. manual undercuts to choose the right way to entertain your project. So, by the end, you can optimize your production with minimal material wastage.

What Are Undercuts in Machining?

Standard cutting tools cannot machine features like undercutting and creating recessed areas in a workpiece. Engineers incorporate undercuts in their mold design while using them for keyways and mechanical components needing interlocking joints. Improper machining can lead to poor surface finishes, material stress, and reduced part functionality.

Advanced Machining Strategies for Undercuts

Multi-axis CNC, electrical discharge machining (EDM), and undercut-specific tools solve these difficulties. Engineers use CAM software to create virtual toolpath simulations that detect collisions while improving operational efficiency. By simulating cutting conditions, you can minimize errors, ensure smooth production, and maximize part durability.

Methods for Creating Undercuts

Different machining operations give different levels of accuracy and efficiency. For instance, EDM provides good results for hard materials, CNC milling gives good accuracy, and manual works for customizing. Selecting the right method helps you achieve the desired results. Let’s discuss each technique related to undercut machining.

CNC Milling for Undercut Machining

Undercut CNC Milling

Image Description: A close-up image of a CNC milling machine performing an undercut operation

The precision and efficiency of CNC milling make it a leading technology for undercut machining applications. Additionally, machinists can perform it for designing recessed features through specialized tools. These include T-slot cutters, lollipop cutters, and keyseat cutters. The selection of appropriate machinery tools determines machining operations’ precision level and operational performance. Moreover, multi-axis CNC machines increase tool accessibility, enabling engineers to get undercuts with tolerances as tight as ±0.005 mm. Milling is optimal for aerospace, medical, and precision engineering applications.

Electrical Discharge Machining (EDM) for Complex Features

EDM Undercut Machining

Image Description: The image shows an EDM (Electrical Discharge Machining) process creating an undercut in a metal part.

EDM is another ideal option for machine undercuts, especially in high-hardness materials. It involves using an electrically charged electrode to accurately erode material to form complex shapes. In addition, unlike conventional cutting, EDM does not involve mechanical stress. It is suitable for applications with ultra-fine tolerances and intricate features.

Manual Machining for Custom Undercuts

Although CNC and EDM are more effective, manual machining techniques are still used for low-volume production and custom projects. When automated solutions are not possible, skilled machinists use hand tools, custom jigs, and fixtures to create precise undercuts. This approach requires more expertise but is flexible for specialized apps that need hand craftsmanship.

Furthermore, it helps you get high-quality undercuts with the best efficiency, allowing good performance and functionality of the machined components.

Tool Selection for Undercut Machining

Undercut End Mill Tools

Image Description: The image displays a set of undercut end mill tools designed with extended necks and small cutting heads.

Choosing the right tool is key to getting high precision in undercut operations. Manufacturers use lollipops, T-slots, and dovetail cutters for their required work. The right tool selection often leads to required results in terms of tolerance, accuracy, and precision requirements.

Lollipop Cutters for Multi-Axis Machining

Lollipop cutters are standard equipment for machinists who work with multi-axis CNC machines. Spherical end mills are similar to these tools and provide effective access to challenging locations. They can smooth and cut undercuts with rounded cutting edges in hard-to-reach areas, making them perfect for medical devices and aerospace components. Their working depth ranges up to 40-50 mm, and their cutter diameters are 3 to 20 mm.

Keyseat and Dovetail Cutters for Specialized Applications

Keyseat cutters are specialized tools that cut narrow undercuts in shafts and gear keyways. Dovetail cutters have sharp cutting edges that give high accuracy, and engineers can maintain a tight tolerance of ±0.005 mm. These are used for the machine interlocking features for strong mechanical joints in components that require accurate alignment.

T-Slot Cutters for Deep Undercuts

The machining process for deep horizontal undercuts in mold manufacturing and keyway cutting depends on T-slot cutters. Their tool diameters range between 10 and 50 mm. These tools offer excellent stability and good tool deflection.

Coating and Material Considerations

The cutting tool selection usually depends on material hardness, undercut depth, and desired surface finish. Besides, the tool coatings of titanium nitride (TiN) and titanium aluminum nitride (TiAlN) have been chosen by engineers as they increase tool durability and tool life. The selection of appropriate cutting parameters produces high-quality workpieces with optimal functionality. By selecting the proper tools, you can guarantee precise and durable operation with harsh applications. They help in gaining the following benefits:

- TiN increases the lifespan of tools by 200% to 300%.

- DLC increases wear resistance

- TiAIN increases resistance to generated heat.

Challenges in Undercut Machining & How to Overcome Them?

Undercut machining involves challenges like chip evacuation, tool accessibility, and complex programming. Implementing proper strategies and tools helps overcome such challenges. Let’s discuss the main challenges and their approaches to overcoming them.

Tool Accessibility Issues in Undercut Machining

The biggest challenge in undercut machining is access to the tools. Standard cutting tools do not reach undercut areas, which causes machining errors. Conversely, the multi-axis CNC machining system allows machinists to set tools in proper orientations and reach all areas. T-slot cutters, together with lollipop cutters, remove precise material from tight spaces.

Chip Evacuation and Surface Finish Issues

Chip removal is a critical operational challenge during undercut machining. Chip entrapment in sharp undercuts results in reduced surface quality and accelerated tool deterioration. Moreover, optimized feed rate settings with high-pressure coolant systems help engineers increase effective chip removal, resulting in fewer machining defects and longer tool life.

Programming Complexity and CAM Optimization

Specialized CAM software enables experts to perform cutting-condition simulations for simple program creation and precise tool movement control. In addition, The technique improves precision and shortens production times while eliminating useless equipment movement. Engineers use these solutions to save on efficiency and rework costs.

However, manufacturers can overcome common challenges with the right techniques and increase machining efficiency. They can also obtain high-quality undercuts and maintain consistency in precision components. As CNC machining and specific tooling have improved, industries can perform undercut machining to demanding design requirements.

You can contact us if you have any confusion, or queries, or need information. Our Professional team at PremiumParts can help you optimize your product from prototyping to machining to finishing.

Comparison between CNC Vs. Manual Undercut Machining

Undercut machining is an important part of making complex objects with precise features. Manual and CNC machining are the basic choices, and their choice will determine the efficiency and output of the project. Let us see how these two costs are: precision, tolerance, and overall performance.

Table: Manual VS CNC Undercut Machining

| Feature | Manual Undercut machining | CNC Undercut Machining |

| Speed | Slower production speed,

and primarily dependent on operator skill level. |

50-100% more

faster production |

| Precision | Normally, they fall between

±0.01 mm, depending on the operator. |

Highly precise with minimal

error chances |

| Automation | It needs constant

supervision and manual setup. |

Minimal to no human intervention

with fully automated operation |

| Cost | Low initial cost

(around $1,000) |

High initial investment

(around $100,000 or more) |

| Ease of use | Needs proper

operator skill and experience. |

Ease in operation with proper training |

| Tolerance | Depending on the

operator experience level ±0.01 mm to ±0.05 mm |

Can be done with

±0.005 mm and more precision. |

| Maintenance | Requires very minimal

maintenance for the machine |

Needs regular

hardware and software maintenance. |

| Standard

Compliance |

Manual work is hard to

comply with quality standards. |

It follows ISO 9001

standards for high quality. |

Best Practices for Undercut Machining

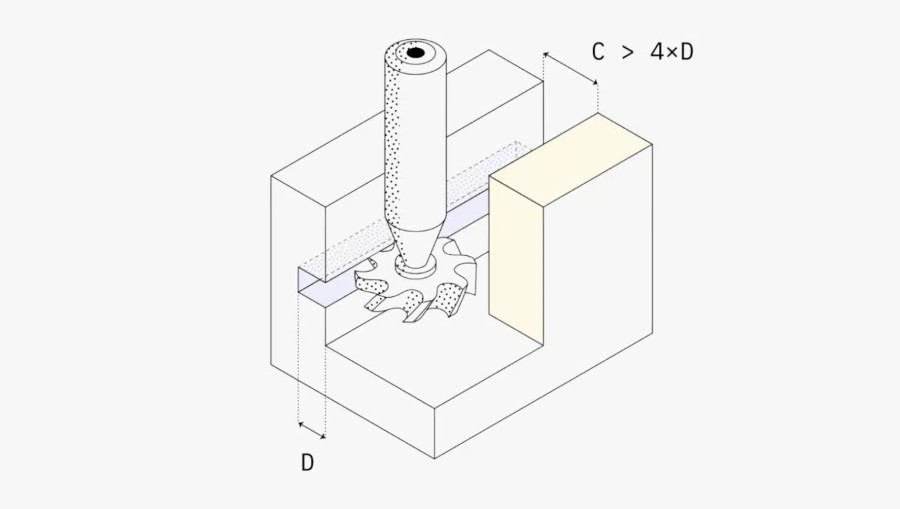

Axis Undercut Machining Illustration

Image Description: The illustration shows an axis-based undercut machining process, clearly indicating how the tool approaches the recessed area from a specific angle.

Below are some practices to achieve maximum results from undercut machining.

Right Tool Selection

Using the right tool will also ensure accurate undercut machining. Engineers prefer lollipop cutters for deep recesses and T-slot cutters for grooved designs. Carbide tools have long tool lives and high precision.

Optimized Machining Strategies

Multi-axis CNC machining operators have better access to tools in confined areas to work on complex elements. Moreover, engineers achieve continuous machine operation by implementing toolpath simulations, which eliminate equipment collisions. Surface finish quality improves when spindle speeds are adjusted along with feed rate reduction.

Proper Workholding & Fixturing

Workholding security is a fundamental mechanism for stopping vibration and ensuring accurate dimensions. Machinists stabilize workpieces by implementing customized jigs and soft jaws. Engineers apply accurate designs to their fixtures to create uniform undercut depths and precise dimensional requirements.

Cooling & Chip Evacuation

Cooling is efficient to prevent overheating and extend tool life. The coolant system improves chip removal. In addition, engineers use air blasts to clear debris from deep undercuts to provide a smooth machining process.

Continuous Process Monitoring

It monitors tool wear and machining errors in real-time. In the process, machinists use metrology tools to measure part dimensions while the part is being machined. The parameters of adaptive control systems are adjusted for optimal results.

Material Considerations for Undercut Machining

The choice of materials determines how well tools perform during machining operations and their overall durability. Engineers assess the hardness, thermal conductivity, and wear resistance to find suitable materials for undercut machining operations.

Commonly Used Materials

For undercut machining, the following materials are commonly used:

| Material | Properties |

| Stainless Steel 304 | High Corrosion Resistant |

| Aluminum 6061 | Lightweight and high machinability |

| Titanium (Ti-6Al-4V) | High Strength |

| Brass C360 | Good Chip Evacuation |

| POM (Delrin) | Less Friction |

Effect of Material Hardness on Undercuts

When working with hard materials, processing time increases alongside tool deterioration, so machinists need to use carbide or coated tools to maintain efficient operation. Additionally, Plastics and composites need precise cutters made for their machining because they tend to deform easily.

Coatings & Lubrication for Material Optimization

Coating of TiN and DLC improves tool life in abrasive materials. The desired surface finish and no thermal expansion are obtained by using appropriate lubricants.

Knowledge of material properties allows you to achieve high-quality undercuts. It involves selecting the right combination of tool material, coatings, and cutting parameters for efficiency and precision.

Inspection & Quality Control in Undercut Machining

Below is an overview of the different steps and stages of inspecting the end product quality and accuracy.

Dimensional Accuracy Verification

The precision of tolerances and measurements depends on machinists’ use of Coordinate Measuring Machines (CMM). Moreover, accurate feature verification through optical measurement tools makes it possible to ensure dimensional consistency in difficult-to-access areas.

Surface Finish Assessment

Engineers use profilometers to measure surface roughness, which enables them to obtain quality finishes with Ra values ranging from 0.4 to 0.8 µm. In addition, the high level of precision eliminates the requirement for extra polishing operations, thus cutting down on both time expenses and production costs.

Non-Destructive Testing (NDT)

Engineers utilize ultrasonic and X-ray inspections to find internal defects in parts without causing any damage which results in structural integrity across aerospace and medical sectors.

Inline Quality Control Measures

Real-time tool offset adjustments through automated probing systems enable proper process monitoring. Moreover, advanced systems function to adapt to minor deviations, resulting in precise machining throughout the entire process.

Quality control procedures enable engineers to maintain accurate and dependable undercut machining procedures. The manufacturing process benefits from advanced metrology tools alongside inline inspection systems, ensuring accuracy while improving surface quality and optimizing manufacturing efficiency.

Final Thoughts

Precision manufacturing requires undercut machining. Engineers use specialized tools and advanced CNC to achieve tight tolerances. Comparing CNC and manual methods aid manufacturers in determining which one is the best for them. Quality and efficiency are directly related to material selection, tool coatings, and machining strategies. Production is consistent through regular inspection and quality control. Improving manufacturing performance makes it possible to understand the undercut machining techniques. Whether for aerospace, medical, or automotive applications, precision matters. It is the best practice to help reduce costs while increasing results.

Contact Premium Parts for Expert undercut solutions and machining. Our high-end technology and expert teams will help you optimize your products.

FAQ’s

Q1: What is the undercut machining process?

It means creating internal or external features that are not directly accessible by a tool.

Q2: What is the advantage of CNC undercut machining?

CNC machines are more precise and yield faster production and consistent results.

Q3: How accurate can manual undercut machining be as compared to CNC?

Accuracy can be obtained through manual machining. However, the precision can be lower and may vary depending on the operator’s skill and human error.

Q4: Can CNC machining be more expensive than manual machining?

Although the first cost is higher, CNC machining is more efficient in the long term and costs less.

Q5: How can I choose between CNC and manual undercut machining?

You can choose based on the following main factors:

- Complexity of design

- Machining Budget

- Production Volume