We know all products, especially machinery, are made of different parts. And the dimensions of these parts make or break the whole product structure. Thus, the geometry and dimensions of the parts are crucial. Any lag in the structure of the parts can ruin the production of parts. We use a measuring machine that checks the dimensions to eradicate this concern. A CMM machine ensures the parts meet the design specs and quality of the final product.

It maintains the production process and offers better quality control. In this article, we will discuss the CMM machine, its components, and its advantages. Let’s dive in without any further due.

What is a CMM Machine?

Aerospace CMM Machine

Aerospace CMM Machine

Image Description: A large aerospace-grade CMM machine is inspecting a metal aircraft component, showing the probe and gantry structure clearly inside a clean metrology room.

No matter whether the product is big or small, its manufacturing depends upon its components. The precise dimensions and geometry of those parts ensure the quality of the results. People usually use conventional methods such as hand and optical measuring tools. However, to measure the parts’ dimensions manually, you need extraordinary skill. Besides, humans are inclined to make mistakes, so the chances of errors are also high.

On the other hand, a CMM machine measures the dimensions of the parts with coordinate technology. CMM stands for Coordinate Measuring Machine, which measures the parts’ height, width, and depth from different angles.

What is the Use of a CMM Machine?

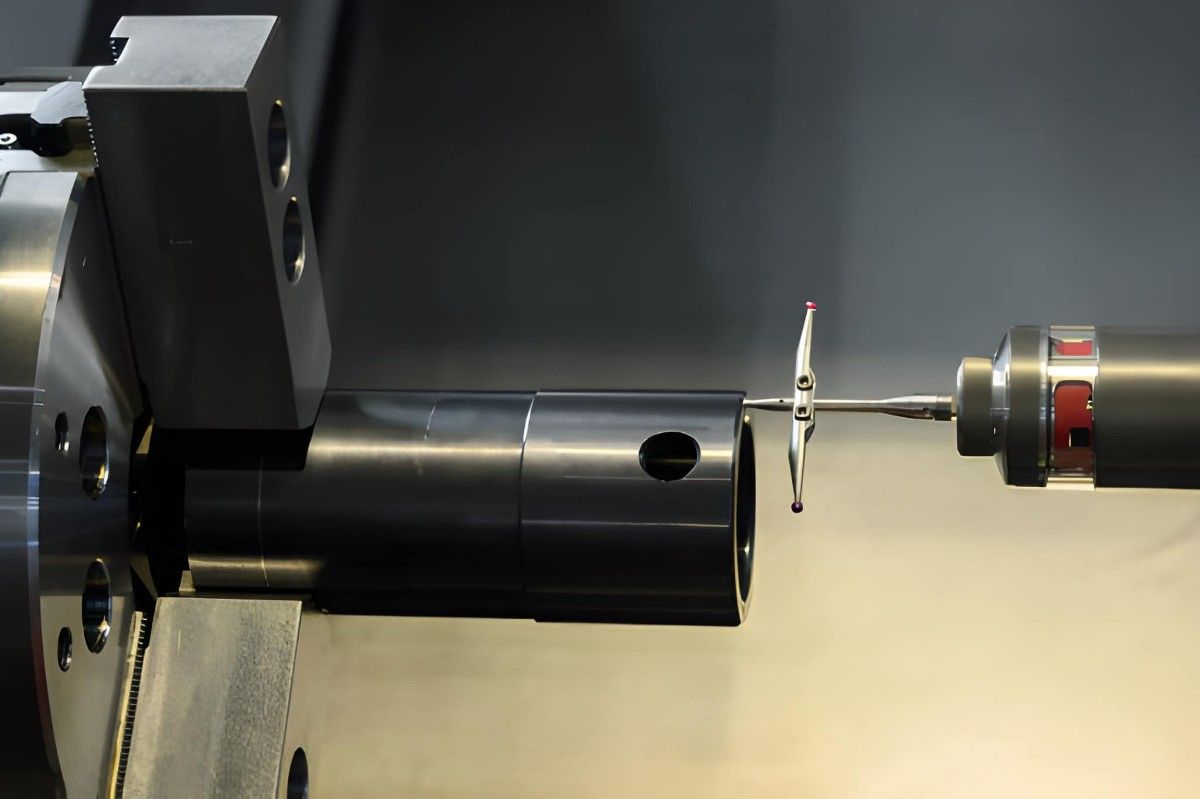

CNC Lathe Chuck Touch Probe Inspection

CNC Lathe Chuck Touch Probe Inspection

Image Description: A close-up of a CNC lathe with a touch probe inspecting a metal workpiece held in the chuck, demonstrating precise dimensional measurement during machining.

Answering this question is very simple: measure the dimensions of parts in the manufacturing industry. You must understand the uses of technology and how it overlaps worldwide. So you can learn the difference between traditional and new methods for measuring parts.

As we described earlier, traditional methods are prone to mistakes. They have limitations and rely upon the operator’s skill. Besides, the qualities of high-level measuring and precision are not everyone’s cup of tea. Moreover, this century facilitates luxury and quality, so its insurance is a must.

Similarly, today’s products are usually complex, so the best approach is to give them a one-to-one rival for checking precision. Thus, the CMM machine comes into play with its high speed and accuracy. It can simultaneously measure multiple parts repeatedly. Moreover, it reduces errors and time waste, which results in productivity.

How to Use a CMM Machine for Measuring?

Metal Surface Inspection

Metal Surface Inspection

Image Description: A close-up view of a metal part being inspected for surface finish and dimensional accuracy.

You must be curious about the workings of CMM. How can a machine check the dimensions of a part automatically? There are two methods to take the measurements. The first method includes the contact mechanism to check. The second method uses a camera or lasers to measure the object’s geometry. However, both methods have variations in the sizes and shapes of the parts under analysis. The big CMM machines can measure even more significant parts up to 10m in size.

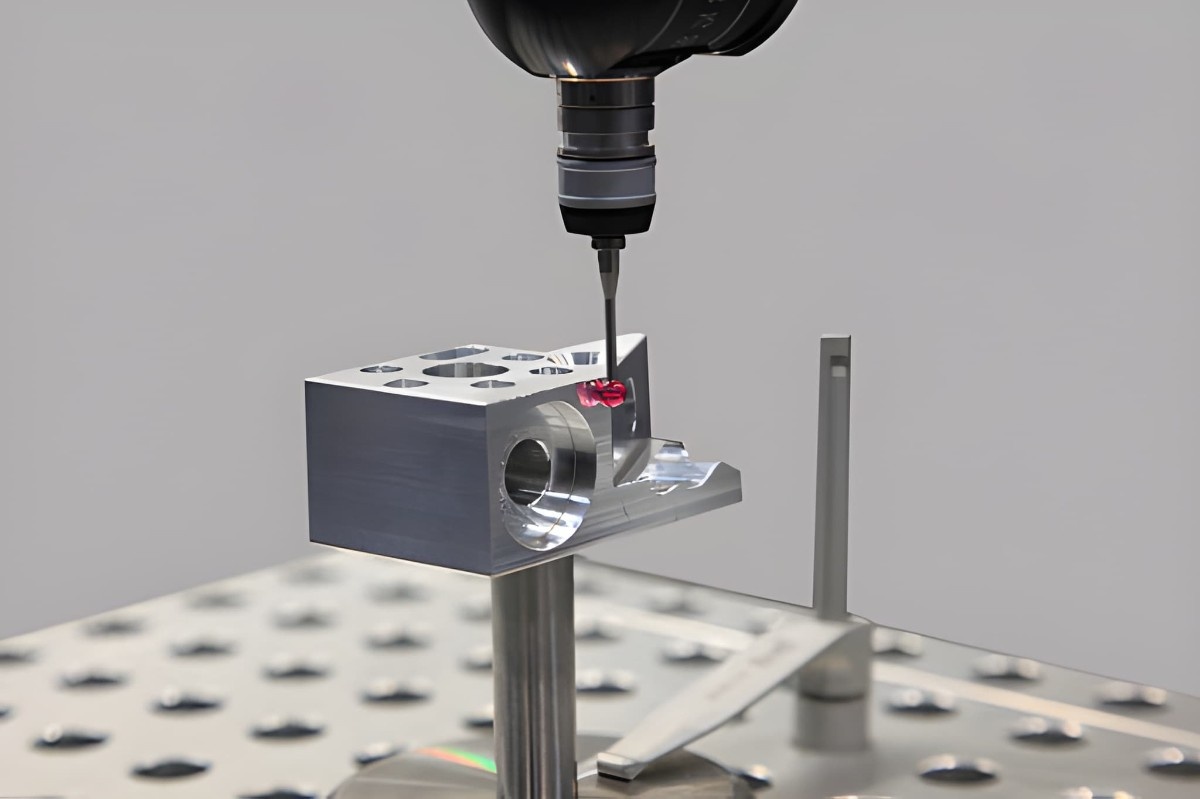

Working of the CMM Machine

CMM Inspection of Mechanical Part

CMM Inspection of Mechanical Part

Image Description: A coordinate measuring machine checking a machined mechanical component using a touch probe to capture dimensional data.

The CMM measuring machine has a moving axis above the base where the product is placed. It checks the part’s dimensions with the touching probe attached to the axis. Moreover, it analyzes the parts according to the design and structure of the final product. Here are the steps for working on CMM:

- Placement of Part in Machine: To measure the part, you place it in the base of the machine. The base is stable and hard, offering the best site for placement. It ensures the stabilization of the measuring process and guards against external forces.

- Moveable Axis: Above the base, there is a movable axis of the machine that also features a touching probe. This axis can control the tendency to touch the part from different angles. During this, it measures and copies different dimensions of the object.

- Mapping of Electrical Singles: While touching the points of the part, the probe sends electrical signals. These signals go to the computer, and after processing, the device gives the output of the dimensions.

- Analysis: After the measurements, we analyze the dimensions captured by the probe. Usually, the computer records the dimensions of different products. This helps compare the final design with the possible outcome of using that particular part for that design.

- Camera and Laser Method: The process is the same for machines that use cameras and lasers. They just take pictures of the parts from different directions, and the computer measures them. In lasers, the laser beams touch the part to take measurements.

The Components of a CMM Machine

CMM machine’s definition and usability are generally easy to understand. However, learning about its components and how they function might equip you with something informative. Here are some significant parts of the CMM machine:

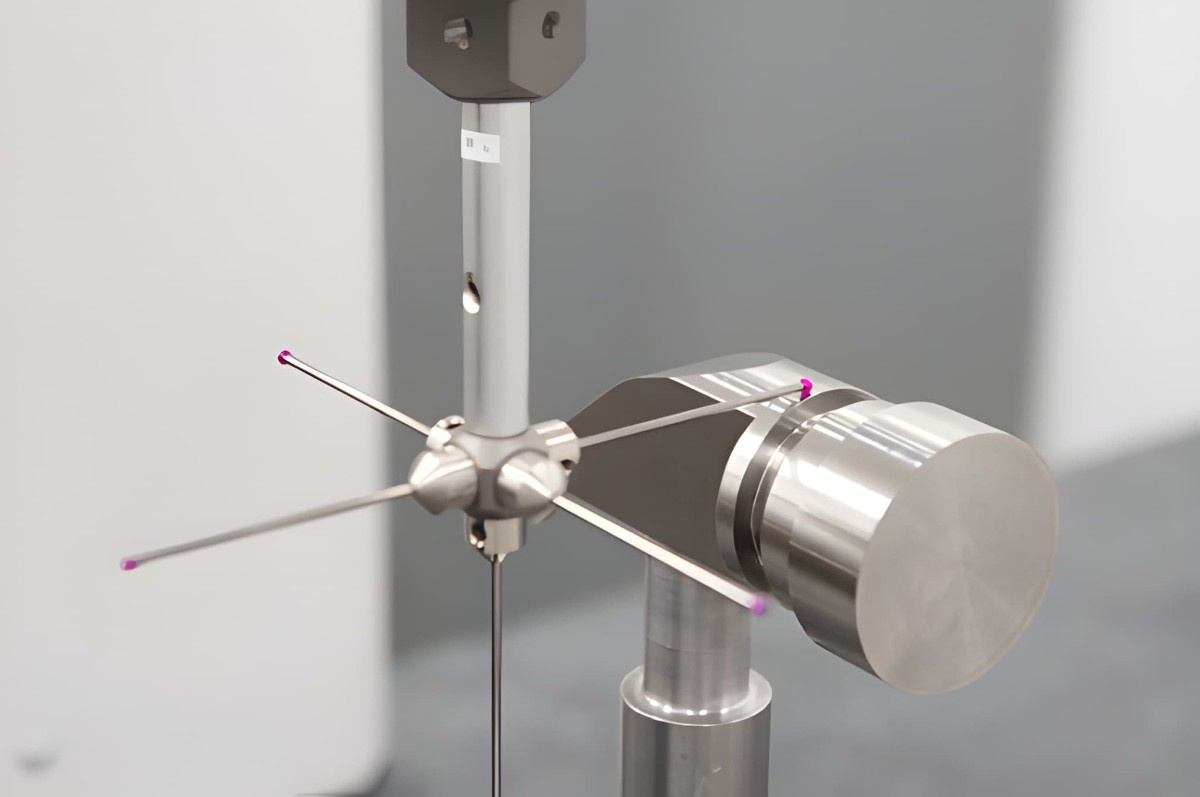

Probe

CMM Machine Probe

CMM Machine Probe

Image Description: A close-up of a CMM probe with a ruby tip, focusing on the stylus and sensing mechanism used for high-precision contact measurement.

CMM machines’ probes are the most significant component. They measure the part and send signals to the computer. Probes can be in any form: light, camera, laser, or metal. The contact probe has a rigid tip made of stable material, usually ruby and zirconia. It should also be resistant to temperature, so its size won’t shrink or expand in case of heat dissipation.

Granite Table or Base

The next important part of the CMM machine is the granite table, which is very stable. The component is prudent to temperate and has high resistance against wear and tear. The use of granite in it ensures accurate measurements as it is durable and does not change easily with time.

Fixtures

Fixtures are the most critical parts of CMM machines, as they support any manufacturing process. They help to keep the part in place and ensure its stability. Part fixation results in precise measurements, as the movement of unstable parts can cause errors. Many types of fixtures are available, such as magnets, fixture plates, and clamps.

Air Compressors and Dryers

The air compressors are the driving force behind the CMM machine. Air dryers remove moisture to eliminate the risk of airborne contamination. These components ensure the machine’s durability and functionality in the long run.

Software

Although not a part, we can link it to the functionality of the machines. The software analyses the probes, controls their motion, and notes the measurements. After that, it analyzes them and gives us results.

Types of CMM Machines

CMM machines ensure that the dimensions of the current part fit well with the original design idea of the product. Here are several different types of CMMs based on their structures:

- Bridge CMM: It includes a probe that can move along three axes: X, Y, and Z. Each axis has a sensor that gauges the probe’s position. The probe detects points on the part’s surface and sends signals to the computer system.

- Gantry CMMs: These are best for measuring large and heavy objects. They have the same design and functionality as bridge CMMs; however, they are larger and do not require lifting the part onto the table.

- Cantilever CMM: The probe measures an object from all three axes. It is different from bridge CMMs as the probe is attached to only one end of the base.

- Horizontal Arm CMM: This model features a horizontal probe that can measure long and thin objects. It’s also best for measuring complex parts with difficult geometries.

- Optical CMM: These do not require contact with the parts. They include an optical triangulation method that measures from all three sides. They are fast and accurate for measuring many parts.

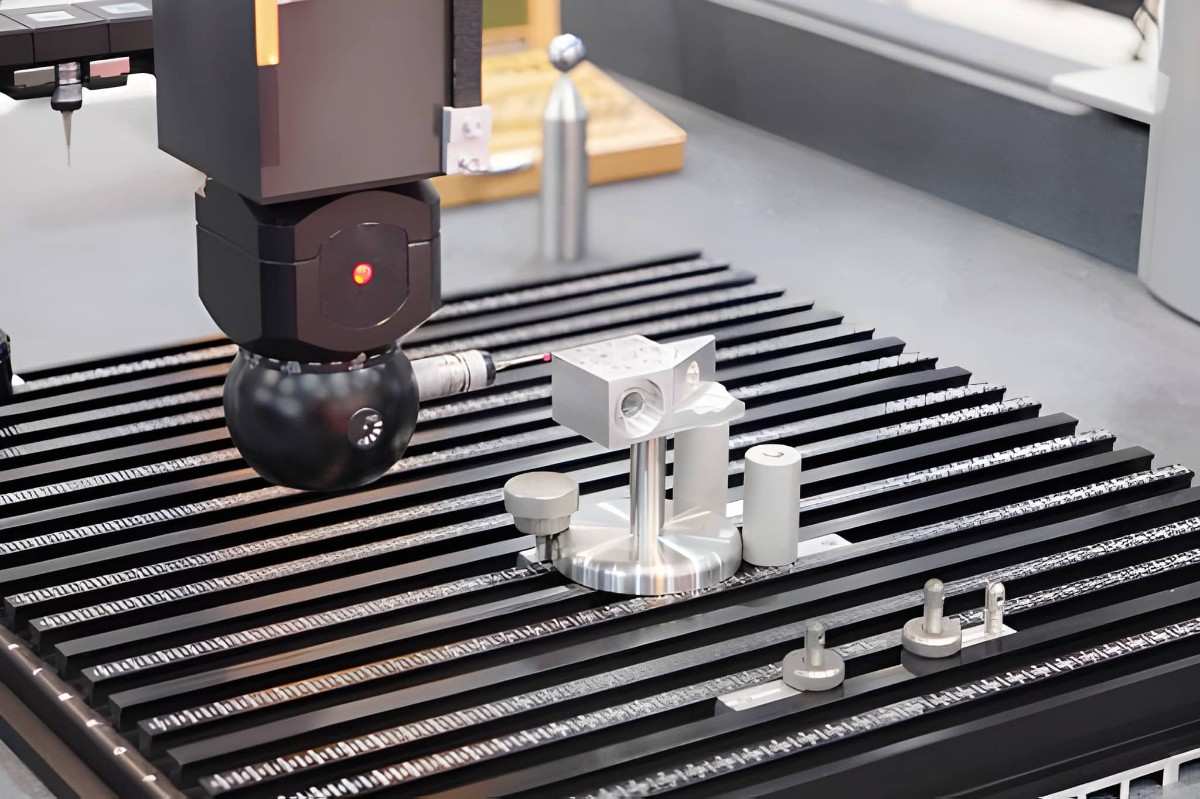

Advantages and Disadvantages of CMM

Machine Tool Inspection

Machine Tool Inspection

Image Description: Machine tools arranged on a table being inspected for precision and quality.

In the big industries, CMM should be a part of any manufacturing process. It’s because it offers more and takes less. With minimal limitations, it helps to achieve maximum results of high quality. Let’s learn the advantages and cons in detail:

Advantages

Here are some significant advantages of the CMM Machine and how they help in enhancing your workflow:

– Save Time and Money

CMM Machines save time and money because of their fast and accurate measurements. They are necessary in any production process of complex tools. This machine can easily evaluate the part’s dimensions, which helps to produce more at less cost without errors.

– High Quality and Precision

CMM machines, using machinery’s supremacy, give more reliable results than conventional manual methods. They can easily measure parts from different axes and provide analysis. They’re the most beneficial tool when it comes to ensuring quality.

– Versatility of Components

Unlike traditional methods, CMM machines are compatible with different types of tools. From using a camera to a laser, they can easily measure any complex part.

– Reduction of Workforce

You don’t need to hire someone with great expertise to measure the parts, but expertise comes at a cost. The CMM machine features an automatic computer system that provides accurate and error-free analysis.

Disadvantages

CMM machines are the best tools for improving production workflow and precise outcomes. However, they also have some limitations that you should consider as well:

– The Probe Touching

Machines with touching probes can deteriorate the part. Rigid and stronger parts can endure as the probe touches the part from different axes. However, fragile parts can’t. So, one must be careful when probing using the contact method.

– Soft Parts are Subject to Defects

When the prone touches them, the soft parts may change shape, ruining their appearance. For example, take rubbers into account; the probe can cave them in while touching them.

– Right Probe and Cost

You need to select the probe carefully, considering the dimensions, material, and size of the parts. Touching the soft parts might not be a good option. So, you will need a camera or laser probe, which can cost more.

FAQs

Q1: What’s the usability of the CMM Machine?

The CMM machine measures the dimensions and geometry of the parts using coordinate technology. It measures the height, width, and dimensions from the X, Y, and Z axes.

Q2: What are the benefits of using a CMM machine for measuring?

The CMM machine provides accurate measurements that enhance the production workflow. Moreover, it makes fewer errors than conventional measuring methods. Besides, it digitally analyzes the part and gives an in-depth report in digital form.

Conclusion

A CMM machine is a tool for measuring the dimensions of a part. The above article will familiarize you with the CMM machine’s process, components, and advantages. However, integrating it into the manufacturing process is not easy. So, it’s best to outsource the parts with precise shapes and dimensions.

At Premium Parts, we also provide detailed analysis of your products’ dimensions. Whether you want to use CNC machining, 3D printing, or even Injection molding, we can measure any resulting part. Contact us now to get a quotation and ensure the smooth operation of your company.