Before the widespread adoption of additive manufacturing, CNC machining, rapid prototyping techniques, hardware design, and product design iteration were usually sluggish at best. This is due to the numerous phases of conventional product development. Before the digital age, scientists and engineers would first write/draw out the design or idea on paper, propose several hypotheses, research the best-fit materials and then build the product. In the cases of errors and failures, the consequences were painstaking and arduous; the engineers would need to return to square one, investigate and retry.

Why Digital Prototyping Alone Isn’t Enough

Many newbie product developers often drag their design iteration and spend ample time in the digital phase. For many, this is where the pursuit of perfection must end. Sadly, this is not the case. Unless your product is an electronic concept that will be used intangibly, digital iteration can never be enough. Here’s why:

- Each phase informs the other: The feedback from physical versions will be used to refine the digital concept.

- Scale does matter: Some percentage of the original size may scale down in digital iteration. Having a physical version will inform the spatial relationships, putting the bigger picture in view.

- Evaluating functionality: Do the parts function as they should? Do they fit into one another? Does the chosen form enhance how the product performs and behaves?

- Sense organs: Physical iterations can help you see, feel and even smell what the product is like. You also get to understand how texture plays a role in the product’s usability.

Preparing Your Digital File for Prototyping

Step 1: Preparing Your Digital File for Prototyping

Designing a 3D Engine Model

Designing a 3D Engine Model

Image Description: A design engineer working on a computer to create a 3D engine model.

The chosen production method will determine the type of digital file you have. For rapid prototyping, CNC machining and 3D printing are most common. For 3D printing, you should have an STL file. STEP files are most common for general manufacturing. You may also have a CAD or CAM file for CNC-ers. Whatever the case may be, ensure that you have properly formatted and saved the file appropriately, as it is not uncommon to have errors in digital files when converting.

Step 2: Tracking Versions for Smarter Iteration

Now that the digital file is ready, save the file while documenting the version in the document properties. Assigning a version to a file helps keep track of what is in that build, the modifications to be made, or that have been made from the previous version.

Versioning also allows you to compare new iterations with previous designs should the need arise.

Step 3: Moving from Digital Design to Physical Prototypes

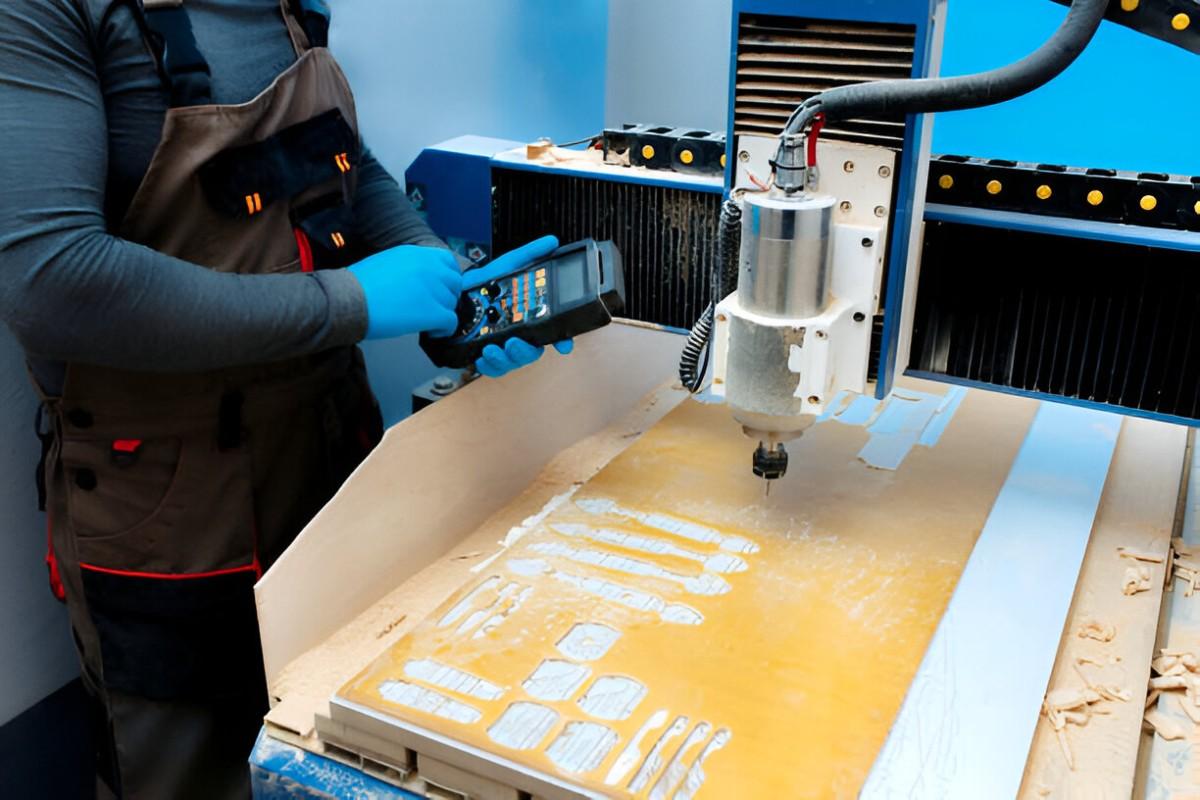

Aircraft Component CNC Milling

Aircraft Component CNC Milling

Image Description: An engineer or technician operating a CNC milling machine in a lab, turning an aircraft design capable of GPS surveillance into a physical part.

Lastly, send the most recent version of your digital file to your team members, manufacturing partner, and supplier for inspection and critique. Since this is your first design to be printed, there should be very little feedback on the design’s functionality and performance. Once you have gotten a green light, it is time to manufacture the physical prototype.

After the physical prototype has been manufactured, begin to run tests based on the critical parameters for your design. Evaluate the product for functionality, strength, form, design, and performance in real-life or simulated environments. The testing is the last stage before you return to your digital file. The results obtained here will be the blueprint that guides you in effecting all the required changes in your design and bringing it one step closer to the perfect product.

Partner with Premium Parts for Rapid Prototyping

At Premium Parts, we offer excellent 3D printing, sheet metal, CNC machining, and rapid prototyping services that can help you optimise your budget, develop prototypes, and facilitate market entry. Stay ahead of the curve and contact us today for all your rapid and low-volume manufacturing services.

With our product engineering and design iteration expertise, we can help you move from idea/concept to physical prototypes in several days. Please feel free to contact us for a free quote.