One of the many advantages of CNC machining is the decent level of cosmetic appearance evidenced in its finished parts. And while many product developers will take decent, more often than not, metal parts will require some extent of post-machining touches to emphasise the true elegance, aesthetic, and even functionality of the part. Here are eight standard metal finishing options for perfecting your metal parts.

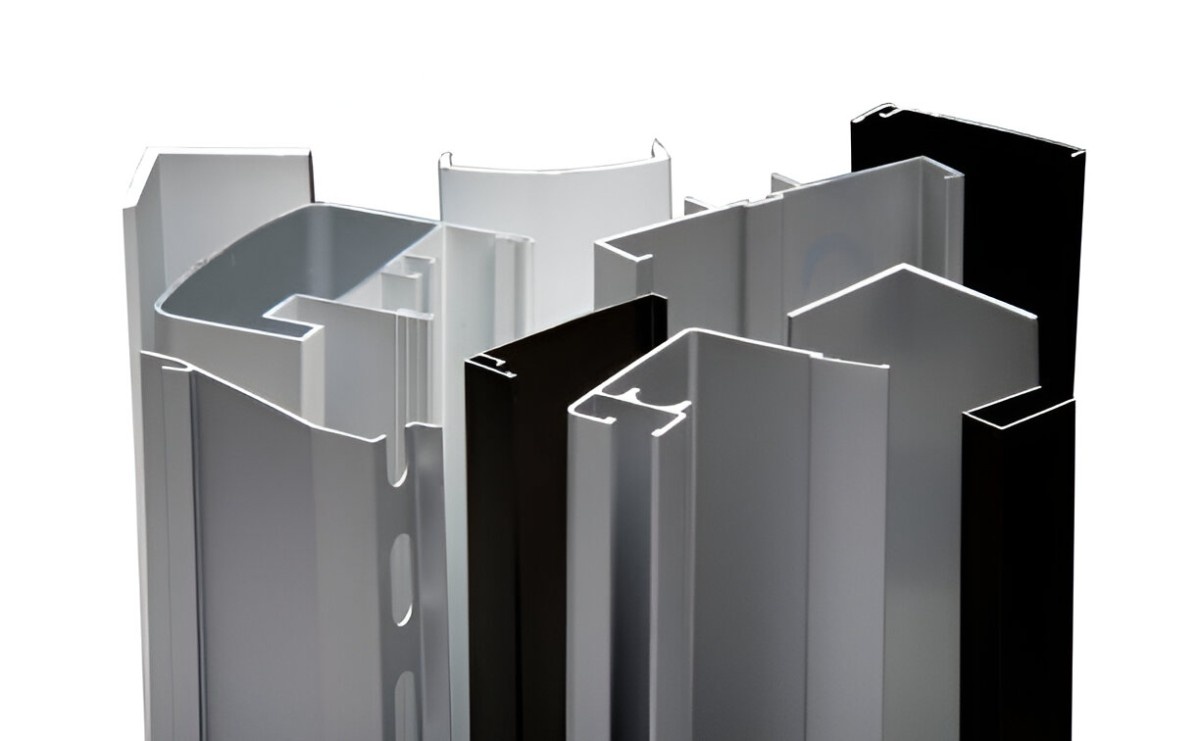

1. Anodising

Anodised Aluminium Profiles for the Window

Image Description: The image shows anodised aluminium profiles for windows, arranged neatly with a smooth surface and metallic finish.

Anodising is a surface treatment, protection, and cosmetic-enhancing finishing technique that adds additional thickness to the inherent oxide layer found on the surface of aluminium and metallic parts. It will prevent the surface of the part from corrosion and scratching. When used in conjunction with an array of coloured dyes, it can result in parts of different colours.

2. Laser Etching and Engraving

Automatic Laser Engraving

Automatic Laser Engraving

Image Description: The image shows an automatic laser engraving machine operating on a metal part, engraving numbers or brand identity.

Laser etching and engraving are used to add standout details, text, logos, or symbols on finished metal parts. The technology works by tuning lasers at high frequencies at the metal parts to achieve the desired pattern. Most metal parts with serial numbers, part numbers, popping patterns, and high-contrast symbols are all etched with lasers.

3. Powder Coating

Metal Powder Coating

Metal Powder Coating

Image Description: The image shows a factory operator using a spray gun for metal powder coating.

As the name implies, Powder coating involves coating the metal part with dry polymeric powder. This technique leverages the variances in electric potential to use electron charges to stick a coat to a part.

The process uses an electrostatic gun to charge the spray powder to a positive state. This powder adheres to the metal part and is heat-cured to make the finish permanent. The advantage of powder coating is the many colours that can be experimented with. It also adds thickness to the walls of your part, so if a dimension is critical for you, you may want to consider how this technique influences your design.

4. Polishing

Polished Automotive Safety System Components

Polished Automotive Safety System Components

Image Description: The image shows polished automotive safety system components on display.

If you’ve ever seen a shiny, mirror-like finish in a high-grade metal part, you can achieve it through polishing. Polishing is a cosmetic and functional finishing technique that delivers parts’ clarity, reflectivity, or transparency. Because of the level of labour required, the technique can be relatively expensive, so it’s well worth it to wait till you’re producing your final parts for market entry.

5. Brushing

Steel Brush for Cleaning off Old Metal

Steel Brush for Cleaning off Old Metal

Image Description: The image shows a steel brush used for cleaning old metal surfaces.

Brushing is used to produce a dull polished finish on metal parts. The finish resembles a satin-like texture, and the procedure uses a 120-180 grit belt. The finished part retains some metallic lustre and inherits a pattern of parallel lines arising from the brushing action.

Unlike anodising, brushing may inhibit or weaken the natural oxide layer in some metals because abrasion is involved in the process. This can enable rusting in the metal parts. It is particularly recommended for decorative products, such as watches and jewellery.

6. Sanding

Sandblasting

Sandblasting

Image Description: A person sandblasting a surface using a blasting gun.

Sanding is a basic yet versatile metal post-processing technique. It is done with a gritty sandpaper, which depends on the desired texture and level of finish. Through sandpaper, the metal can inherit a smooth lustre, uniform, semi-smooth, relative to the size of the grit in the sandpaper. The downside of sanding is the cost and the time it takes. The time it takes to sand a metal part largely depends on the metal’s hardness. The advantage is that the numerous levels of texture can be explored through sandpaper grit sizes.

7. Plating

Hard Chrome Plating of Shaft Metal

Hard Chrome Plating of Shaft Metal

Image Description: The image shows a close-up view of hard chrome plating on a metal shaft.

Metal plating is a finishing process that delivers on both cosmetic and protective fronts. The procedure involves coating the surface of a metal part with a thin layer of another metal. The thin material (plate) protects the metal surface from corrosion and rusting (oxidation). Plating can also be used to alter the cosmetic appearance of metal to resemble the plated metal. Chrome, Zinc, Tin, and Nickel are the most common plating techniques. Carbon steel and copper are the two metal materials that are most plated.

8. Media blasting

Media Blasting

Media Blasting

Image Description: A part showcased after media blasting

Media blasting is a metal finishing technique to convey a smooth, matte finish post-processing. The technique can use various materials, referred to as the media, to apply the desired texture in the metal by firing these small, gritty materials at high speed. Common materials used in media blasting include sand and glass.

Premium Parts Finishing Services in China

Please take advantage of our extensive range of finishing services to create your product in the way you desire. Explore our standard metal part finishing services and contact our production experts to discuss how best to deliver aesthetic and cosmetic superiority to all your metal parts. Get in touch with us now and receive your free quote!