In machining, understanding the difference between precision and accuracy is essential for producing high-quality parts. These terms are often used interchangeably, but they represent two distinct concepts that directly affect ...

As an engineer, you know the gap between design and production is not simple. A part model might appear accurate on your CAD Design, but before it arrives at the workstation, you may experience delayed deliveries, erratic produ...

You’ve got a product idea. Perhaps it could be a manufacturing part, a unique gadget, or something that might make people’s lives easier. Maybe you’ve even made a sketch, and you’ve even designed a 3D model on your computer. Yo...

So you’ve got this part in mind. Maybe it’s a simple bracket, a housing for a gadget, or a custom metal piece for a new product. You’re not looking to mass-produce it—at least not yet. You just want a few solid, precise prototy...

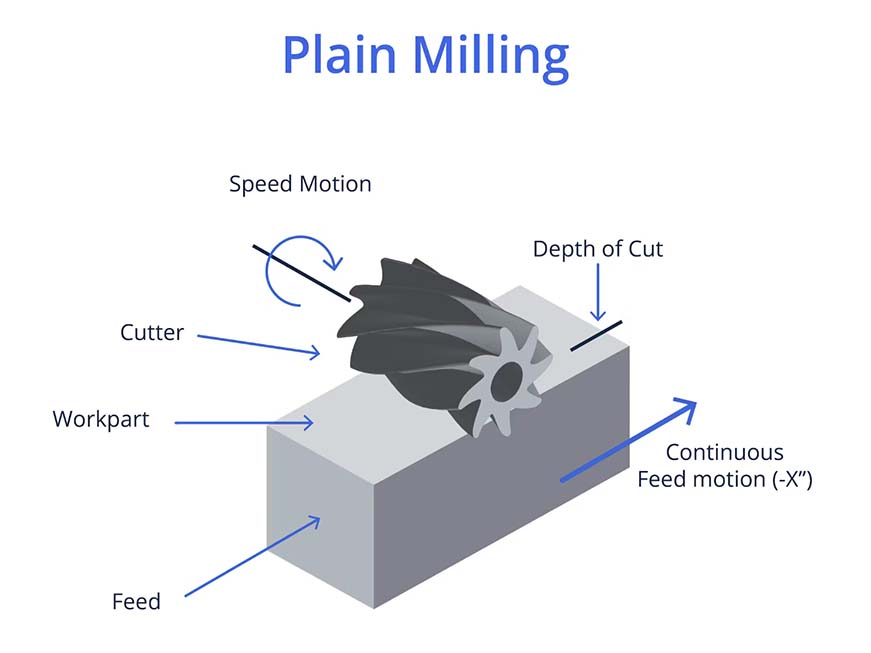

Introduction In the plastic to metalworking sectors, meeting tight tolerances remains a critical task. In many sectors, achieving consistent results, uniform surfaces is challenging to part performance and reliability. Plain mi...

In today’s competitive manufacturing environment, businesses face immense pressure to maintain efficiency, minimize human errors, and deliver precise parts quickly. Conventional manufacturing processes are inefficient, causing ...

The high precision machined components are a major part of many innovative industries. These parts feature high precision, tight tolerance, and quality finishes with incredible chemical and physical characteristics. From metal ...

It’s a typical task to estimate CNC machining cost. Because one project costs you less, but some other projects could incur unforeseen costs. Complex designs, vague cost breakdowns, and excessive material waste can quickly push...

The modern industry demands quality and precision. From heavy industries such as automobiles and aerospace to the health industry, each relies on precision parts. So, if you are a business owner and need quality parts for your ...

You’re working on a life-saving medical device. Everything’s running smoothly…until one small component fails. Why? Because it was made with basic 3-axis machining and couldn’t meet the complex geometry you needed. The part loo...

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.