Avoiding custom machining puts your business at a competitive disadvantage. The global machining market includes more than 30% of conventional and 70% of custom machining. When you cannot source the parts directly from the supp...

How can manufacturers reach tight part tolerances while maintaining their parts’ accuracy? Why do many industries prefer CNC machining over conventional means? The answer lies in its speed, repeatability, automation, and ...

CNC machining is no doubt the cost-effective solution for creating parts and equipment. With the invention of new technologies, it is still steadfast on its ground. The manufacturing industry relies on CNC Prototyping for effic...

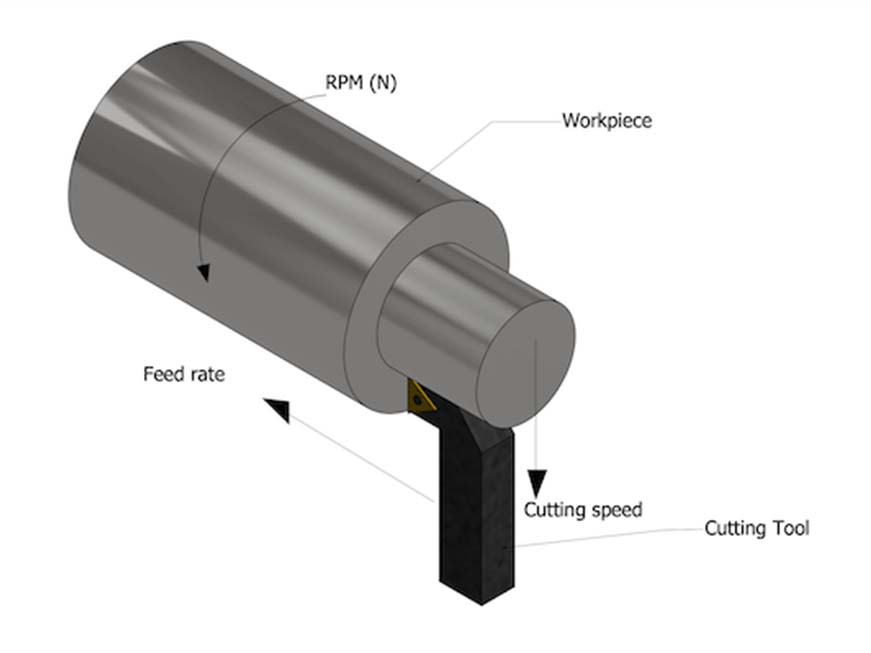

During machining operations, machinists often face issues like overheating, part damage, or poor surface finish. Do you experience chip buildup, chatter, or improper material spread? Such problems appear when machining paramete...

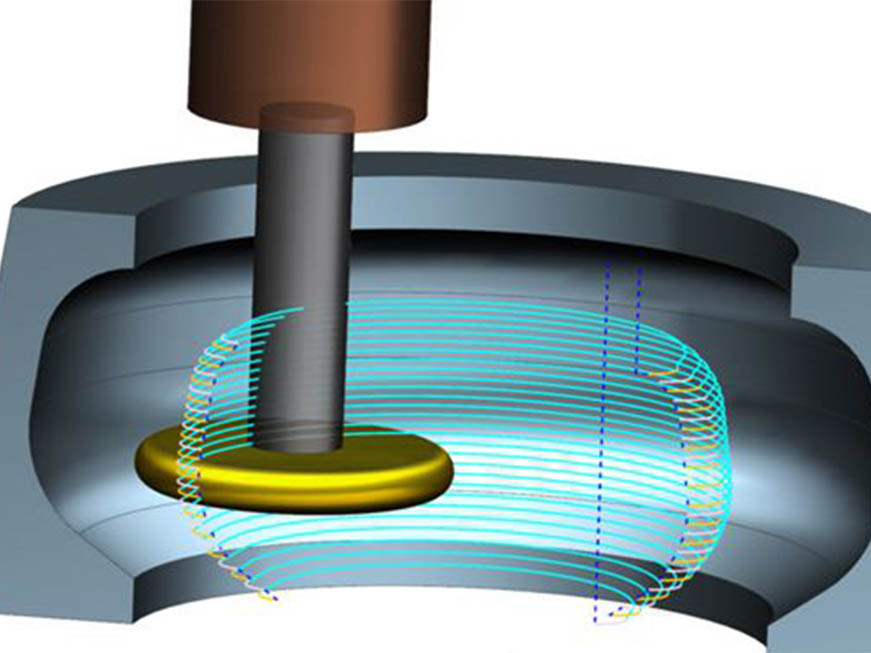

Precision Machining demands high accuracy and a uniform surface finish. But have you thought about how manufacturers achieve complex shapes with high precision and tight tolerance? Standard cutting tools lack the capability of ...

Every component in our modern world, from screws in your kitchen cabinets to sophisticated parts within the spaceship, shares one thing: CNC machining is likely used to manufacture them overwhelmingly. CNC technology enables pr...

Holes are a major part of machinery that offer it different functionalities. Some holes are to maintain the aesthetic appeal, while others are to bind or assemble parts. The manufacturing industry is a highly precise industry t...

The manufacturing industry is vast, and multiple techniques exist to make one product live. From creating the parts to joining and turning them into masterpieces, machines undergo a long process. However, one must be careful of...

Undercut Machining Image Description: The image shows a CNC machine performing undercut machining, where the tool cuts beneath the surface to create a recessed feature in the metal part. Standard cutting tools have limits when...

In the metal removal process, milling uses rotary cutters, which separate extra portions from the input material in an efficient way. Manufacturing companies rely heavily on milling operations to perform accurate material swaps...

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.