In modern manufacturing, choosing the right material for your project is essential in building efficient, yet long-lasting products. Now, this is where bar stock and plate stock come in. They are among the most used raw materia...

Rubber overmolding is a two-stage process. It is used to increase product grip, absorb impact, and add comfort, all in one step. Additionally, it reduces the need for additional assembly. The process is used in aerospace, gun, ...

Kovar alloy machining is an essential technique in precision manufacturing. It requires two things: a lot of patience and a skilled technician who knows the right way to operate the machinery and tools. Kovar itself is a metal...

Electro Galvanizing is a surface finishing treatment. It is typically applied to steel parts, products, or components. It is used when parts need forming after coating. The process provides corrosion protection without disrupti...

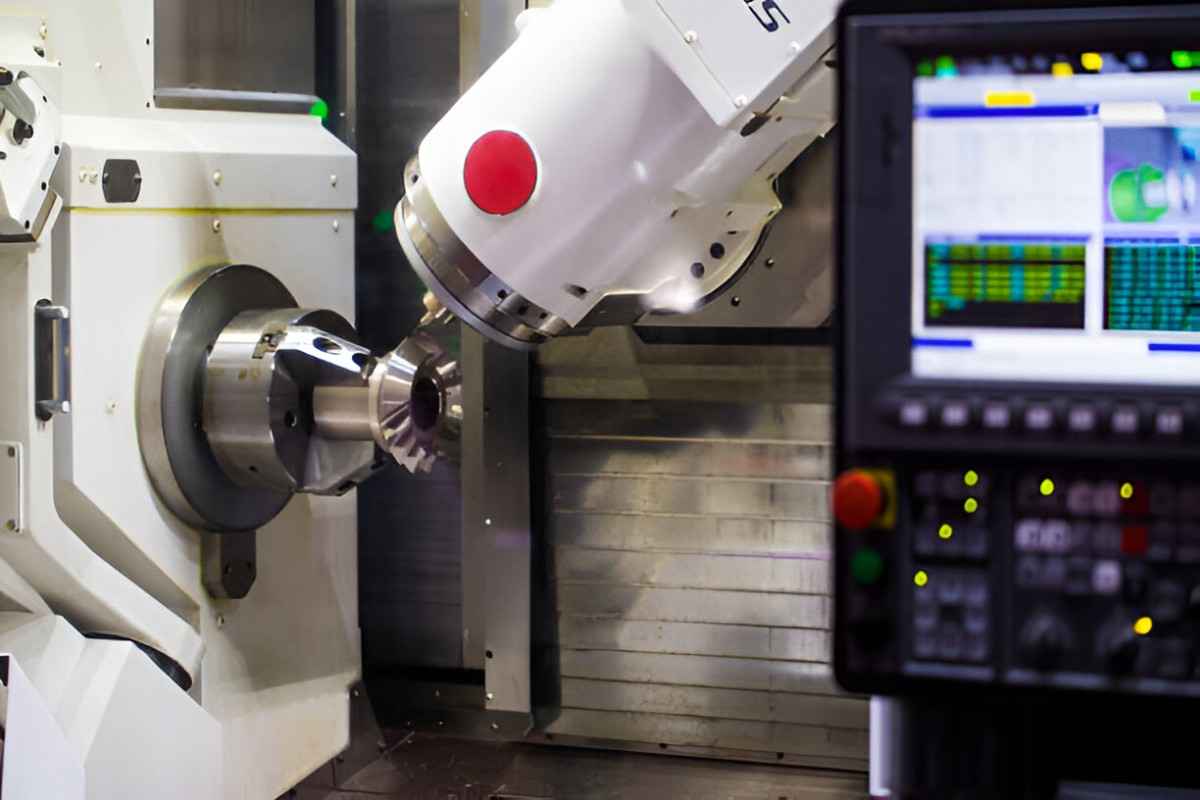

CNC machining has changed the manufacturing process by automating cutting, drilling, and turning. It is extremely accurate and produces parts of better quality than manual methods. Among multi-axis machines, 3-axis and 4-axis m...

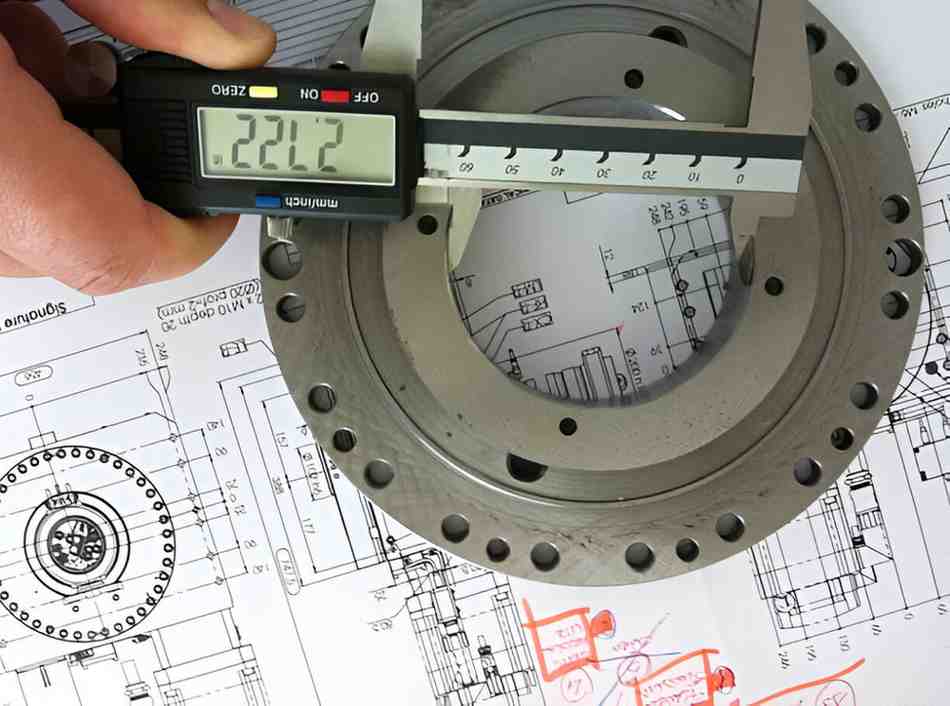

In CNC machining, tolerance defines the acceptable variation in part dimensions, while allowance is the intentional gap or overlap between mating parts. Two common terms ”Tolerance vs Allowance” are used interchange...

In precision manufacturing, even the smallest of details carry great importance. They can affect how an entire system appears and functions. Among such details is a burr – a sharp edge, rough ridge or a raised area left b...

Smart homes are no longer the talk of the future. They are our present, and this present relies solely on precision. From sleek smart locks to voice-controlled lighting systems, each smart project needs reliable internal compon...

Introduction Inevitably, machining complex parts often leads to expensive mistakes. Any small mishap might lead to a waste of raw material, and there would be a considerable delay in the production schedule. Striking the right ...

Imagine This: You got a great product idea, you researched it well, rendered it in CAD software, but it failed during testing. If you have actually built it and tested it thoroughly, you could have spotted all the cracks. In th...

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.