With precision and efficiency, CNC turning machines by Premium Parts Manufacturing Limited are revolutionizing the manufacturing world. If you have never used a CNC turning machine but are interested in how it works, well, now is your chance to learn. It might not be rocket science, so even if you’re not technically savvy, you’ll learn every step of the way without any difficulty. By the end, you’ll know exactly how to operate a CNC turning machine and appreciate why it’s a vital part of modern manufacturing. Let’s dive in!

What are CNC Turning Machines?

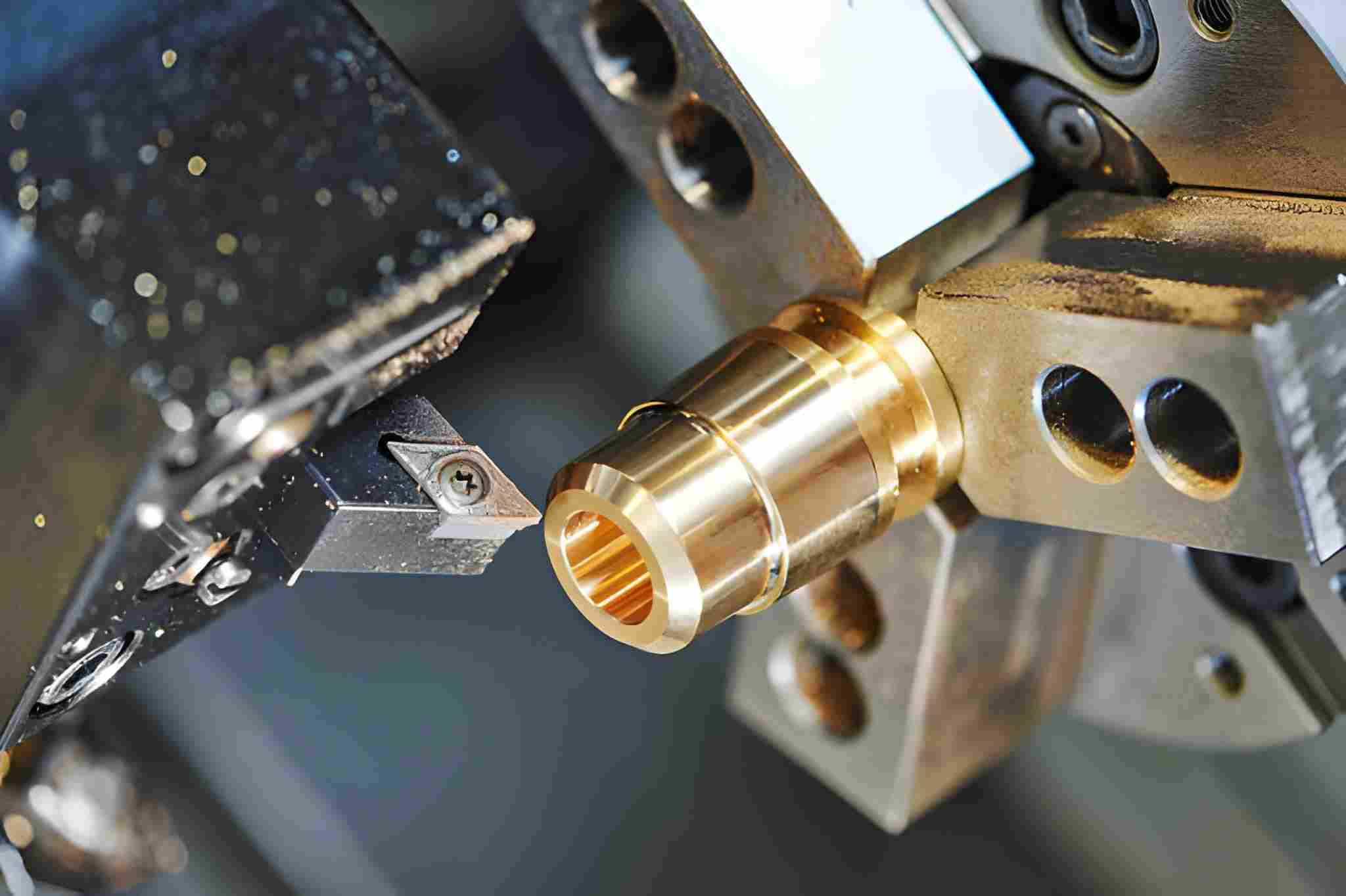

CNC Brass Turning

CNC Brass Turning

Image Description: A CNC lathe machine precisely turning a brass rod, producing a smooth, shiny cylindrical component.

Before we jump into the steps, let’s first understand what a CNC turning machine is. CNC stands for Computer Numerical Control, which is just a fancy way of saying the machine is controlled by a computer program. A CNC turning machine works like an advanced version of a lathe, but instead of turning knobs and moving tools by hand, the machine does everything automatically.

It cuts, shapes, and finishes materials like metal, plastic, or even composite materials with the help of special software. This makes it super accurate, fast, and consistent every time. That’s why industries like cars, planes, medical tools, and electronics use CNC turning machines—they need parts to be made perfectly and quickly without mistakes.

A Step-By-Step Guide to Operate CNC Turning Machines

Now that you know the basics, let’s get into the main part that involves operating a CNC turning machine with care and safety.

1. Prepare Your Work Environment

Ensure your workspace is clean and safe before even reaching for the CNC machine. A clean environment makes you concentrate better and decreases the rate of accidents.

First, be sure to wear proper safety goggles for your eyes, gloves for your hands, and some ear protection to damp out the very loud noises that accompany the equipment. Next, turn off the machine itself. Lastly, be sure all your tools and materials are handy and neatly in order. Safety is always first when operating any piece of equipment.

2. Understand the Machine Control

Control Panel of CNC Turning Machine

Control Panel of CNC Turning Machine

Image Description: An operator adjusting the control panel of a CNC turning machine.

The CNC turning machine has different parts you need to know before starting. The control panel is like the brain of the machine. This is where you input the program and tell the machine what to do. Next is the spindle, which spins the material, and the chuck, which holds the material tightly in place. Lastly, there’s the tool turret that holds all the cutting tools needed for the job.

Take some time to understand these parts. Most modern CNC machines come with simple screens and easy buttons, so it’s not as complicated as it looks.

3. Load the Workpiece

The workpiece is the material to be shaped or cut. To place it, open the chuck, or, in other words, it’s clamping. Position it so that the material will be safely captured inside the chuck once it is closed. Then, close and hold it firmly to stop the movement of the workpiece on a machine during work time.

It has to be properly aligned. If this is slightly out of line, then the machine can mess up the part or even have accidents. So, take your time in getting this right.

4. Select and Install the Cutting Tools

Close-up of Turning Tool

Close-up of Turning Tool

Image Description: A close-up view of a CNC turning tool cutting a metal workpiece, showing sharp edges and precision chip removal.

Our CNC turning machines use various tools to cut or shape the material. These tools are held in a rotating holder known as the tool turret. Depending on the job you would like to do, you will need to select the correct tool.

One will install the tool by opening the turret, selecting the appropriate cutting tool, and locking it in place. Ensure the tool is plumb and tight so as not to wobble upon cutting. Once all the tools have been mounted, close the turret. These tools are actually important to shape the workpiece in a CNC turning machine.

5. Input the Program

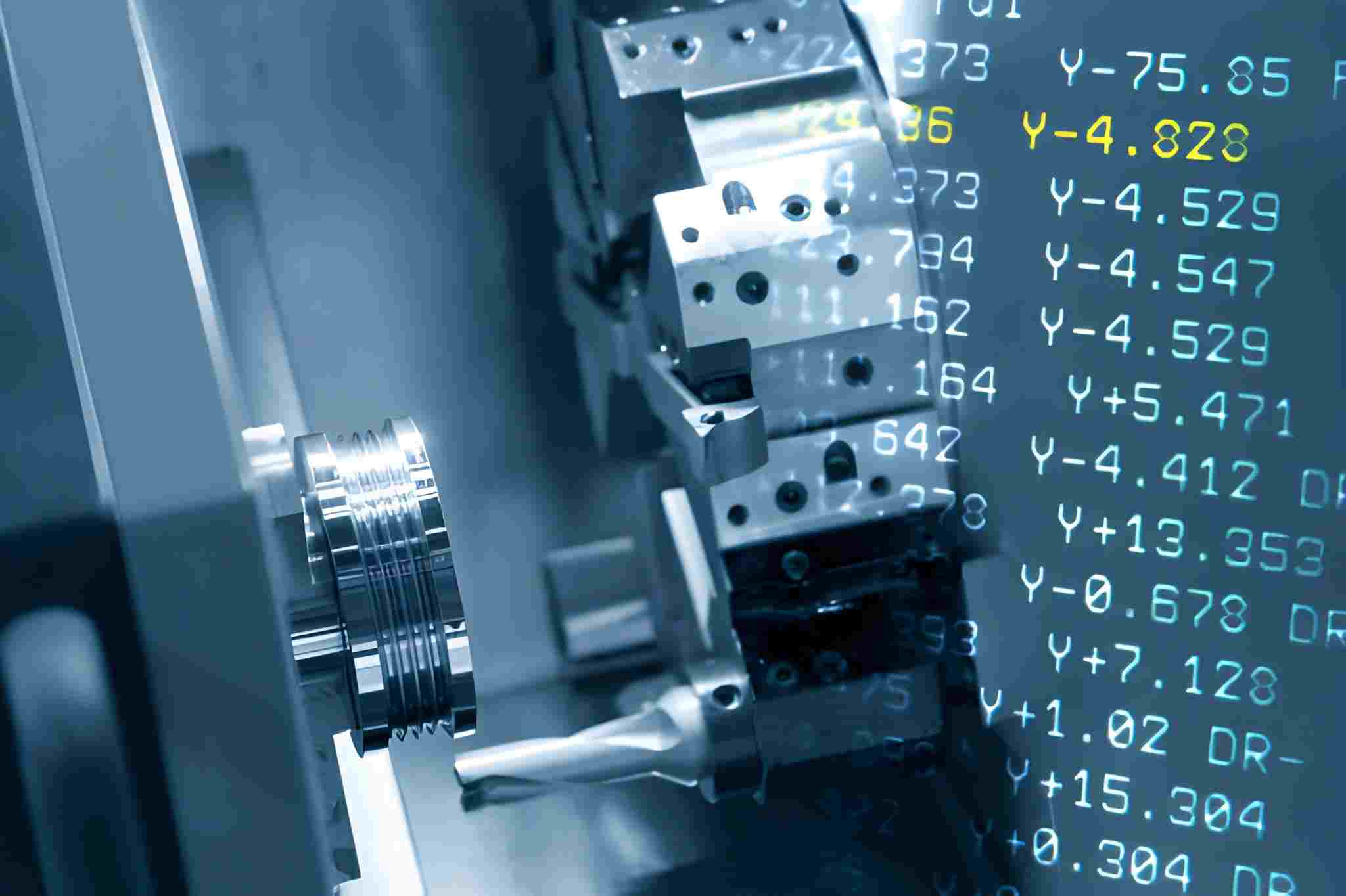

CNC Lathe Machine and NC Code

Image Description: A CNC lathe machine operating with an NC code program displayed on the control screen, guiding precise machining movements.

This is where the computer takes over. The CNC turning machine needs instructions to tell it what to do, and these instructions come from a program. Most programs are written in a special machine language known as G-code. You can either make your own program for designing software or use a pre-existing program. Once you get hold of the program, install it on the machine. You can either transfer it through USB, direct connection, or networking.

Before running the machine, you have to have a dry run. A dry run refers to testing the program without actually cutting anything. It is like checking for the presence of errors in work before presenting it.

6. Set Machine Parameters

Machine parameters are settings that control how the machine works. These include:

- Spindle speed: How fast the material spins.

- Feed rate: How quickly the cutting tool moves.

- Depth of cut: How deeply the tool cuts into the material.

These settings depend on the material you’re working with and the type of part you’re making. If you’re not sure, most modern CNC machines have preset options for different materials, so you can just pick the right one.

7. Start The Machine Process

Once all the preparation is done, it is time to let the machine do its magic. Power on the machine and hit the start button. The machine will follow the program as it cuts, shapes, or finishes the workpiece.

While running, pay attention to the machine. Watch out for some unusual sounds or vibrations that may indicate something is wrong. If everything sounds right, then just let the machine continue doing its work without stopping it.

8. Inspect the Finished Products

Now, you turn off the machine, take out your work from the chuck, and check your work. Now, this is a great time to make use of measuring tools such as calipers or rulers to ensure that they fit the design. Examine carefully for errors. If anything goes wrong, then the program or the settings may have to be tweaked for the next run. You want to know you are always making something right.

Conclusion

It may seem to be a challenging task when one is trying to learn how to operate a CNC turning machine, but with a little practice, it becomes easy. From preparing the machine and loading the workpiece to running the program and inspecting the final product, all these steps are important for getting the best results.

For reliable CNC turning services, visit Premium Parts Manufacturing Limited and discover first-class CNC solutions for you. Now that you’ve learned the process, it’s time to get to work with CNC turning machines.