Every component in our modern world, from screws in your kitchen cabinets to sophisticated parts within the spaceship, shares one thing: CNC machining is likely used to manufacture them overwhelmingly. CNC technology enables precise 3D cutting tasks through a single set of prompts. To fully admire the marvel of a CNC machine, you must realize how it evolved.

Industries recognize CNC machining as more than just a method. It represents a significant change in manufacturing approaches. Moreover, the technology combined computer algorithms and resilient machine tools to make production parameters reach a new level. CNC is not just a passionate dive into a rich past. That’s a peek into the future, where the CNC machine’s background is key to more sophisticated advancements.

CNC Machining Overview

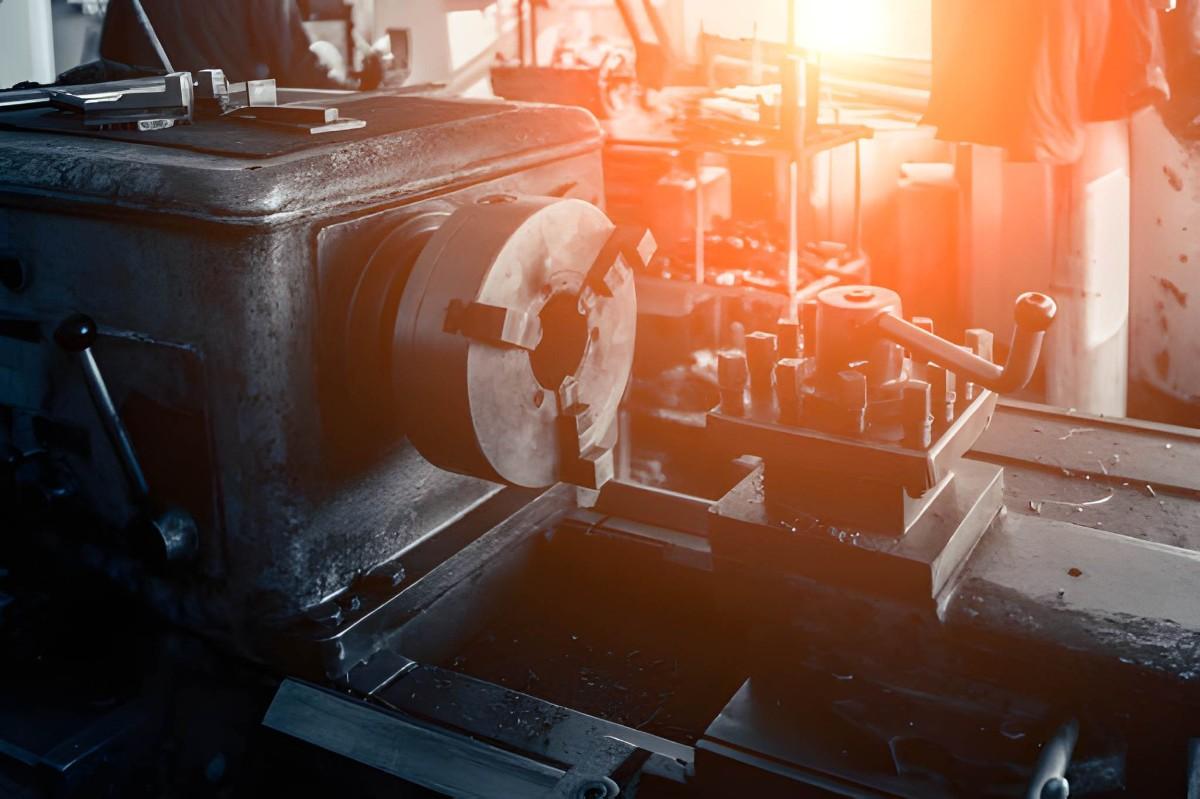

Workshop Lathe Machine

Workshop Lathe Machine

Image Description: A giant metal lathe in a workshop.

CNC (Computerized Numerical Control) machining is a highly advanced manufacturing technology. It allows you to use pre-programmed systems to control the machine tools, like mills, lathes, and grinders, for detailed and complex cutting. Since shaving off materials and turning them into useful products is not possible by hand.

CNC machining programming is the heart of it. A technician designed a computer program that was part of CAD software and typed detailed instructions into it. The machine tool is guided along with every movement and operation exactly as it should be once this program is running. More than that, this innovative approach elevates the manufacturing’s capability and improves productivity and efficiency.

Benefits of CNC Machining

There are many industrial applications of CNC machining. Industries such as aerospace, healthcare, and consumer electronics benefit from its precision and efficiency.

CNC Machining Process is Extremely Precise

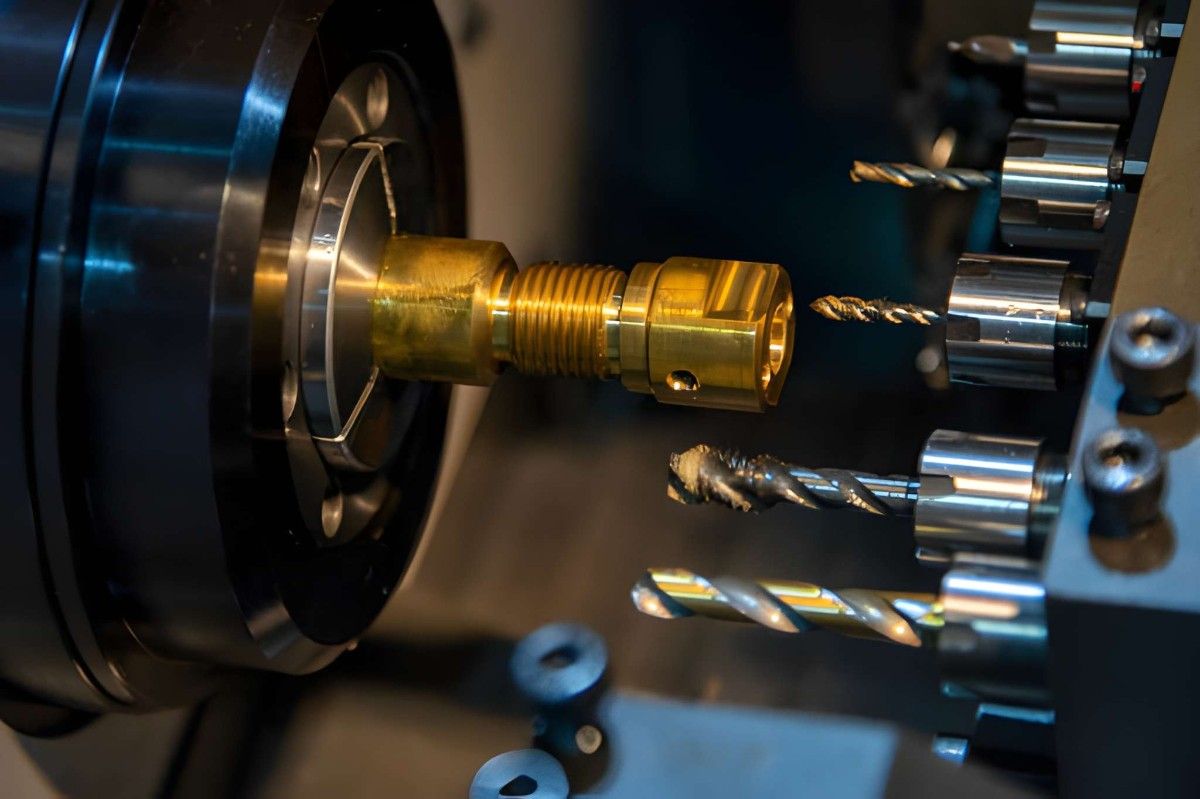

Swiss CNC Lathe

Swiss CNC Lathe

Image Description: A multi-tasking Swiss-type CNC lathe cuts a high-precision brass part.

Many industries require high-precision manufacturing, and CNC machines deliver it consistently. The aerospace industry, in particular, relies on CNC for accurate and reliable parts.

CNC Technology Generates Accurate Parts

Another benefit of CNC machining is its dimensional accuracy. It has CNC programming codes and operator control, enabling it to produce parts as shown in the CAD file with high accuracy.

Range of High-Quality Materials

Phenolics, rigid foam, plastics, and carving foam are commonly used in micro industries. Each category includes different material types, so you can select the properties that best suit your project.

Machined parts from these materials often include electronic device cases, insulation components, and prototypes. The wide range of materials allows CNC machining to produce diverse and versatile parts.

Selection of Materials

CNC Nylon Milling

CNC Nylon Milling

Image Description: A CNC milling machine cuts nylon parts using a solid ball end mill.

CNC machining is often preferred over other manufacturing methods, such as 3D printing. Choosing the right material depends on compatibility and certain other factors given below;

- Heat tolerance

- Stress resistance

- Hardness

- Fastening

- Design tolerance

Premium Parts’ instant quoting platform provides you with a full list of supported materials. Upload your design and start your project today!

CNC History Overview

CNC has a rich and fascinating history of human ingenuity and technological advancement, with a context that is equally important for its future development in manufacturing. The first CNC machine revolutionized the production line and the workflow. An understanding of the origins of CNC tech also brings into focus its stream toward improvement. This also instills us with confidence that the future advances in this technology will be quite awesome.

How and Where CNC Machining Began

The Second World War inspired the history of CNC machining. This technology was developed because of the demand for complex and exact machinery parts, especially in the aerospace industry. Because production of high-quality components for the war required the expediency that only automated methods could produce, innovators began examining automated solutions.

Numerical control (NC) technology was introduced by American engineer John T. Parsons in the 1940s to begin the genesis of the CNC machining process. In designing the first numerically controlled machine together with MIT, he served in the U.S. Air Force. Precise control of re-running the manufacturing operation was achieved using punched tape with the machine.

In the 1950s, MIT engineers used servo motors to improve the operation speed on NC machines. The modern CNC technologies were first demonstrated to the industries with the use of the first computer-controlled machines. The addition of motor-controlled apparatus and numerical control systems is an important step in the history of manufacturing, as machines can perform operations based on preprogrammed instructions.

Evolution of CNC Technology

CNC machines have a unique evolution. Enigmatic would be, to begin with a machine controlled by a punch card and end up with a machine controlled by digitally powered software. The evolution was the cause of CNC machining becoming faster, more precise, and more accurate than NC. Technological advancements contributed to the development of the first CNC machine.

From the 1960s and ‘70s, the production of CNC machining revolutionized the minimum computers and advanced programming languages. The implementation of G-code as their standardized programming language gave machinists more programming flexibility.

The decisive milestone of CNC machining was reached by the 1980s. By integrating microprocessors into personal computers, manufacturers worldwide gained access to universal usage of CNC machines. CNC technology immediately made the jump to the automotive industry and the aerospace sector because it gave them accurate processing and the ability to manufacture components automatically with minimal turnover.

Modern Developments In CNC Machining

Smart Manufacturing Robotics

Smart Manufacturing Robotics

Image Description: Robotic arms in a manufacturing plant assist with heavy industrial production.

Today, CNC machining has reached a groundbreaking level thanks to computerization and constant technological improvements. Modern machines are now more precise, versatile, and efficient than ever.

Many CNC operations can run almost fully automated. Machines with tool changers can replace worn or broken tools without manual help. Some CNC machines also have sensors that detect tool wear and damage, helping plan maintenance before problems occur.

Applications of CNC Machining

CNC machining is widely used worldwide. Companies use it for large-scale manufacturing and small to medium businesses. Choosing the right material is as important as the process itself.

It produces high-precision parts for aerospace, automotive, medical, electronics, and defense. Below are the main applications and capabilities of CNC machining.

Automotive

A major user of CNC machining is the automotive industry. The precision of a CNC machine allows the automobile industry to create components for vehicles that are safe, comfortable, functional, and aesthetically beautiful.

Consumer Electronics

The consumer electronics industry also uses CNC machining, which is unexpected. Companies, including Apple, use CNC machining in their production. A machine shop crafts the aluminum chassis of the Apple MacBook.

Aerospace/Military

CNC machining is vital in Aerospace, enabling the production of high-precision turbine blades, engine components, and structural airframe parts that must withstand extreme temperatures and pressures. In the military sector, CNC technology is used to manufacture firearm components, armored vehicle parts, and advanced missile systems. CNC machining is also a choice, as it can produce different versions of any part on demand and also as a replacement.

Manufacturing Applications

CNC Machining is widely used across various industries, offering high precision, automation, and efficiency in the production of complex components.

Prototyping

The process is autonomous and arguably a good process for making prototypes using CNC machining. By having a CAD file, you can send it to the CNC machine, and fabrication will occur in no time. These properties make it well-suited to prototype making.

Production

The precision and accuracy of the CNC machine are high, and it is an ideal choice for making high-quality components. Furthermore, fabrications with no imaging parts can also be used with a wide material support. As a result, companies using it to prototype also use it to manufacture usable final parts.

Tooling

The direct manufacturing process has extensively used CNC machining, which is considered a gem of the process. Additionally, it plays a crucial role in facilitating various processes in the indirect manufacturing process.

Consumer electronics

CNC machines are used in the electronics manufacturing industry. They produced electronic device components with electrical insulating materials. These materials are designed to prevent electromagnetic interference and radio frequency interference.

Marine Applications

To produce durable, water- and corrosion-resistant components made of polyurethane materials that manufacturers in the marine industry rely on, they depend on CNC machines.

Defense Applications

Good materials are especially necessary for the best equipment available today. CNC machines use hard-coded, strong materials that can handle rough environmental conditions to create custom components.

Production of Medical Supplies and Equipment

Equipment components needed from the medical and biotech industries should follow technological advancements. CNC machining is one of the reasons the medical industry operates.

Computer Technology’s Contribution to the Development of CNC Machining

With the rise of computer technology in the late 20th century, the CNC machining industry experienced a transformation as the CNC machines became more efficient and accurate as well as versatile. The computer’s appearance represents a milestone in the CNC history timeline, as it enabled digital storage of complex designs and automatic correction of errors.

The incorporation of both CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) into CNC machining revolutionized the process of designing and manufacturing components. This was an advancement in the history of CNC machines, a new era of production, with digital cuts made possible and then transferred to the factory floor.

Summary

The operative tape-handling devices developed due to CNC machining technology have continued to become more complex in automated manufacturing systems.CNC machining will help industrial production during technological development and lead innovation forward since it will ensure high precision and work efficiency. CNC technology has become the modern manufacturer’s continuous dependence, and many advanced developments have come to their future.

The history of the work of CNC machining is quite interesting, but the future is even more inspiring. As new computer technology, modern materials science, and continued advancements in automation become possible, the range of CNC machining applications continues to expand virtually to where there is no stopping innovation or experimentation.

And that concludes our CNC history timeline. We trust this overview has been helpful to you. We will continue to share more interesting articles about CNC machining and other related cases of industries.

Contact Premium Parts For Advancing Your Machining Project

CNC machining plays an intrinsic role in a major manufacturing process. Many industries and service companies have adopted it. You can get several advantages of CNC machining services at Premium Parts, such as online instant quotations, design for manufacturing analysis, and strong engineering support.

.jpg)