How come transparent and other plastic parts have smooth and flawless finishes with minimal imperfections? You don’t need to ponder this point much, as the answer is vapor polishing. Vapor polishing is a finish that helps create transparent plastics and lightweight optical quality lenses. Moreover, it’s a premium technique that results in smooth and radiant surfaces. Vapor polishing comes in handy to offer optimal transparency in materials like polycarbonate, acrylic, and other materials.

Besides, vapor polishing has diverse usages, from manufacturing and medical to aerospace and others. Let’s dive into the depths of vapor polishing and how it can help you get maximum and excellent results. Keep reading to explore in more detail.

What is Vapor Polishing?

Vapor Polishing

Image Description: A close-up image of an operator using vapor polishing to refine a plastic part.

Vapor polishing is a technique to enhance the smoothness and transparency of plastic surfaces. In this method, we expose the plastic surface to solvent vapor, such as the volatile gas of Weldon 4. We convert the solvent into vapor and spray it directly on the plastic part. That solvent melts and reflows through the plastic surface at the microscopic level by reacting with it. Subsequently, the technique eliminates surface imperfections, fills in the scratches and voids, and produces a smooth, glossy finish.

In short, vapor polishing intensifies the appearance of materials like polycarbonate and Acrylic (PMMA). Additionally, this method is also beneficial for the surface finishing of internal and small parts. You can polish internal features like threads, apertures, and channels, which are rather difficult to do manually.

How Does the Vapor Polishing Process Work?

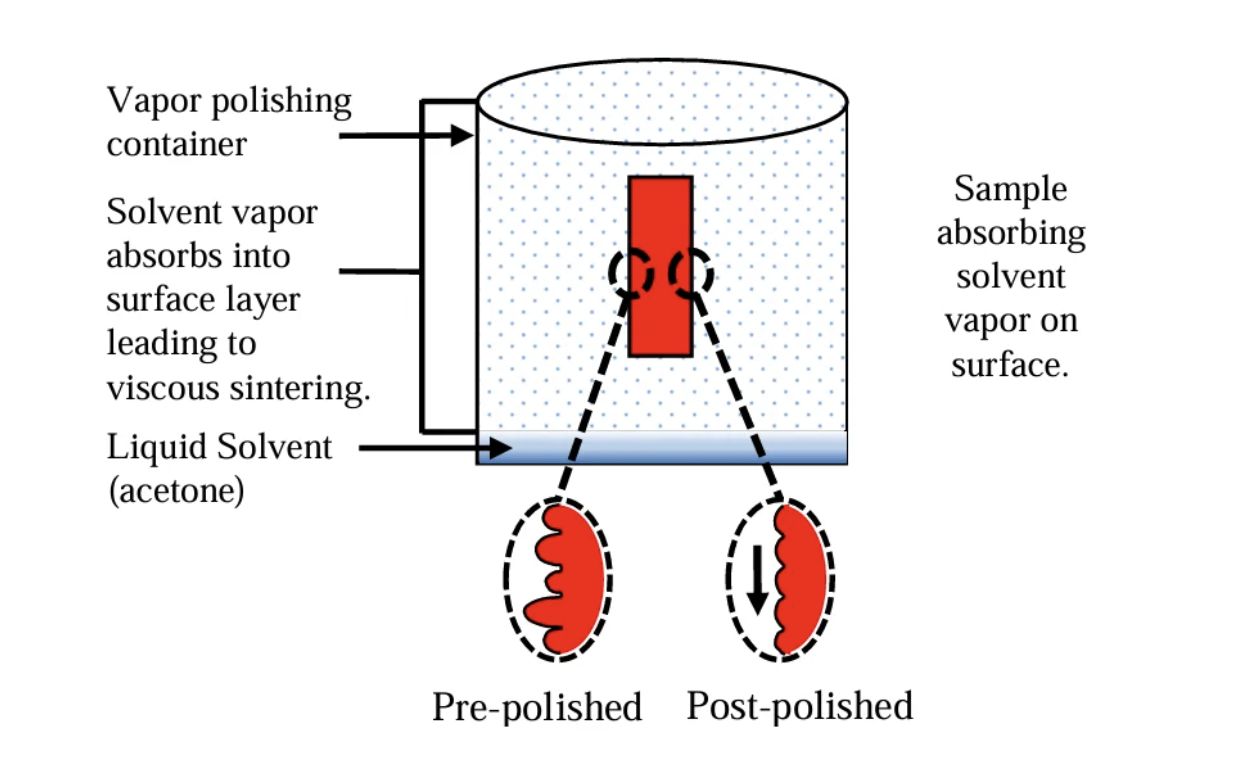

Vapor Polishing Process

Image Description: A detailed process illustration of vapor polishing for plastics. The image shows a plastic component inside a vapor chamber, with solvent vapors surrounding the part. Arrows indicate the flow of vapor onto the surface, which melts the outer layer just enough to create a smooth, glossy finish.

No doubt, vapor polishing is an efficient way to smooth the surface finishes of different materials. However, you must use this method carefully, with proper pressure and temperature control. You can use a solvent like Weld-On 4 or FA 326, as they are highly reactive with polycarbonates. Let’s explore the steps for the vapor polishing process:

- Sanding: The first step involves sanding the workpiece (material) to reduce deeper marks. For this, 1000 to 1500-grit sandpaper is used on the material’s surface, and the material is cleaned to remove dust.

- Placement: Place the material in a closed chamber with a vapor solvent. Moreover, the solvent may require different amounts of time to work on various materials. Consequently, you can choose different solvents of your choice as well.

- Heating Solvent: Heat the solvent to its boiling point (1040°F / 400 °C) until it converts into vapors and surrounds the material. However, maintaining proper temperature and pressure is essential for this step.

- Reaction: Here, the vapor will react with the material and start melting. As a result, the material will undergo liquefaction and readjustment to clear imperfections.

- Remove Solvent: After achieving the desired results, open the chamber and heat it to remove the finishing agent and vapor. Now, the material has no residue. After the process, you can dye, paint, or enhance the material.

- Results: After the chemical melts and clears the voids, the material shines better and is smoother. However, enhancing the shine depends on the quality and processing of the solvent.

Some Major Types of Solvents for Vapor Polishing

Vapor Polished Parts

Image Description: A collection of plastic parts with smooth, glossy surfaces achieved through vapor polishing.

You can use different types of solvents for vapor polishing, and making the right choice is essential. Therefore, always consider a solvent compatible with the material undergoing treatment. Here are some major types of solvents that you can use for vapor polishing:

| Solvent | Specs and Functionality |

| Acetone | A solvent with high reactivity that is effective in polishing ABS (anti-lock brake system) parts. |

| Methyl Ethyl Ketone (MEK) | Best for polishing thermoplastic materials such as polypropylene, PVC, Nylon, Polycarbonate, and others. |

| Tetrahydrofuran (THF) | Ideal solvent for polishing PLA parts such as bottles, screws, pins, plates, and others. |

| Dichloromethane (DCM) | Fastest and most potent solvent for polishing ABS parts. |

| Ethyl Acetate | A slow-paced but reactive solvent is best for PLA parts. Although it requires more time, it also shows the best results. |

Best Practices to Follow for Vapor Polishing

It’s best to carry out vapor polishing with extreme care to ensure maximum results and safety. To do so, you can follow these steps to enhance the efficiency of the process. These steps also benefit your safety and getting things done right. Let’s dive in for more details:

1. Select the Right Solvent

As we have provided earlier, different solvents come with different functionality. Some are good for 3D printing materials, and some are best for minor materials that need intensive handling. You need to know their functionality from Weld-On 4 and methyl ethyl ketone before usage. Besides, you can choose from acetone or dichloromethane for ABS parts. Subsequently, ethyl acetate and methyl ethyl ketone serve the best for PLA parts and thermoplastics.

2. Control the Temperature

Always maintain a proper temperature during vapor polishing. Usually, high temperatures produce quick and smoother results. However, there’s a limit, and beyond that, you can deform the material. Generally, 1040 F or 400 C is best.

3. Safety Always Comes First

Always handle solvents with care, as they are highly reactive and dangerous. For example, acetone is highly flammable at a room temperature of -20 C. Thus, use protective items such as gloves, glasses, and masks before starting and finishing. Also, ensure no exposure to flames and that the area is clear.

4. Sanding and Cleaning

It’s best to clean the material before polishing it in the chamber. Remove the dirt and debris with air or a soft cloth, as they can affect the process. Sanding the part also helps to remove any leftovers. Washing with detergent helps you remove dirt, grease, and leftover oil. Wash properly and dry the material with a soft cloth. If not, you can also leave it for some time to dry manually.

5. Exposure and Part Orientation

Ensure the material gets enough exposure time to react with the vapor solvent. Exposure time is necessary because it depends on the temperature, material type, and solvent reactivity. A precise exposure time is necessary to ensure proper polishing without damaging the material. Moreover, the positioning of the material also affects the polishing quality. Ensure that the part surface you want to polish faces down towards the solvent.

Types of Plastics That Can Be Vapor Polished

You can’t polish all the plastics with vapor polishing as they come with different shapes, structures, and properties. Vapor polishing is best for thermoplastic materials with better reactivity and solubility with specific solvents. Here are some primary plastic materials on which this method works:

Acrylic (PMMA)

Acrylic (PMMA) Polished Part

Image Description: A polished acrylic (PMMA) part with a clear, glossy surface.

Acrylic is best for making optical-quality materials. It has a non-crystalline nature and is lightweight and indestructible. Therefore, it’s perfect for making transparent plastics. Vapor polishing is best for acrylic components as it smooths the surface and erases impurities. Sealing the pits and trenches gives the material a glossy and transparent finish. Thus, the acrylic parts with vapor polishing have less surface friction and a high aesthetic appeal.

ABS

ABS Vapor Polished Parts

Image Description: A close-up image showing multiple identical ABS components with vapor polished surface.

Vapor polishing with acetone is best for ABS as it removes the layer lines and impurities. As a result, you get smooth and highly durable ABS parts. How does this method make parts durable? Of course, smoothening and less friction make the material resistant to wear and tear. So, if you have any material that needs accurate dimensions and a glossy finish, polishing with vapor acetone solvent is best. This method makes the surface more potent and gives an edge to the material, usually in high-performance applications.

Polycarbonate

Polycarbonate Vapor Polished Part

Image Description: A polycarbonate part with a smooth, glossy surface.

Polycarbonate parts usually have rough areas that compromise their smoothness and functionality. When these parts go under vapor polishing, the finish smoothens their surfaces, making them more glossy and transparent. Erasing CNC machining marks and imperfections makes them smooth for optical applications. Moreover, these parts also become durable by removing cracks and pits. With primary medical uses, these polycarbonate parts enhance functionality.

3D printed parts with transparent SLA resin

Vapor polishing also works for some transparent SLA resin. It can make 3D printed parts smoother and transparent. Some 3D printers would like to do post-vapor polishing to make parts more transparent to meet their requirement.

Benefits of Vapor Polishing

Vapor polishing has many benefits, and listing them here is nearly impossible. So, let’s consider some of the significant benefits:

- Premium-surface quality: The finishing helps in creating a smooth, scar-free surface. Whether transparent parts are for optical use or others, they ensure there are no impurities and that the surface glows.

- Water and moisture resistant: Vapor polishing fills the pits and scratches, increasing resistance. This means that whether water or moisture is present, it can’t break the smooth seal powered by vapor polishing.

- Aesthetics and Enhancements: Cleaning the materials with sanding and other methods leaves marks on the surface. However, vapor polishing removes all the impurities, giving a high-gloss finish.

- Durability and Dimensional Privilege: The finish enhances the durability of the materials by enhancing their resistance to external elements. They can withstand wear, tear, and cracking. Moreover, it maintains the material’s original shape without compromising its dimensions.

What Industries Use Vapor Polishing?

Vapor polishing has diverse usage across various industries. From aerospace to the medical and food industry, many companies facilitate the benefits of vapor-polished parts. Here are some major industries:

Aerospace

I’m counting on big, but yes, the aerospace industry prefers vapor polishing to enhance the appeal of the texture of plastic parts. These parts are used in control systems and interiors of airplanes and need extra smoothness and finishes to offer a premium feel. Refinements of parts, for example, in instrument panels, reduce drag and enhance durability.

Medical

Medical equipment needs high precision and durability. Thus, vapor polishing is handy to ensure smoothness and ease of cleaning. Most plastics have scratches and lines, but with this finish, medical products are crystal clear. Besides, they are comfortable to wear and do not accumulate debris.

Consumer Products

In the consumer industry, such as food and automobiles, vapor polishing gives parts smooth finishes. This reduces friction and enhances product visual representation. Similarly, without jigs and molds, the parts become tolerant to deterioration.

Get the Best Vapor Polished Materials at Premium Parts

Vapor polishing is an effective way to get smooth, optically clear, and radiant surfaces. Besides, polishing the interior and smaller parts of the materials is beneficial. However, you must be careful while performing it as it includes a high risk of accidents. But Premium Parts is here to offer you the best polishing results. You can source your vapor-polished parts in any material, from Acrylic to Nylon. We have a long history of manufacturing and serving you with exceptional quality. Thus, you can order with confidence.

Furthermore, our prices are affordable, so you can have high-end finishes by spending less. Got a query or order? Contact us today and get your projects done right!