Design for Manufacturability

Design for Manufacturability

Image Description: An expert is reviewing technical design drawings and checking if the design can be manufactured easily and efficiently.

Design for Manufacturing and Design for Assembly are two closely associated terms in the manufacturing space. DFM(Design for Manufacturing) refers to the optimization of product design for the specific manufacturing process involved in its production. DFA or DFMA (Design for Assembly) is optimizing the design of your part to meet the requirements of both its production and assembly.

DFM and DFMA are critical facets of product development, offering businesses a means of doing away with about 50 percent of manufacturing cost and making production significantly easier and faster without compromising on the quality of the ensuing product.

What is the Rationale behind DFM and DFMA?

Design for Assembly

Design for Assembly

Image Description: A product design shown with parts that fit together in a simple way.

The underlying principle and basis for DFM is quite simple. When a design has been optimized to match the production technique and assembly method, the extra procedures that will usually exist to optimize the design post-production have already been removed. There will also be fewer materials consumed as the process is being run under tailor-made conditions.

Standardization

Standardized designs can reduce material consumption and inventory requirements. This will consequently save cost as only the exact dimensions and allowances required for the production are taken. In the case of prototypes, standardization can make designs and models easier to modify.

Lastly, all your parts and materials will be able to run along with standard components that match the regular production criteria. This is more cost-efficient compared to instances where hardware will have to be modified to meet custom specifications.

Design Compliance

Designing for manufacturing will ensure that your production parts are closest to specifications, if not perfectly even. When parts are standardized, there will be little need for alignment, which may result in a longer run time. Non-conforming designs may even cause damage to the product when running production or regular stops and starts to fix misalignments.

Design Simplicity

Depending on the manufacturing technique to be used, simpler designs may mean less assembly time and effort. If 3D printing is to be employed, design simplicity will make prototype iteration and evaluation faster and easier.

When parts are designed for manufacturing and assembly, other quick assembly methods, faster techniques, and fastening materials will easily be compatible with your production part.

Setup and run time

Setup times are significantly reduced, and digital models are ready to run at the push of a button. DFM also reduces the number of operations involved in each production cycle. If you are 3D printing a part for assembly, DFMA will significantly benefit your process, as misalignments in 3D parts may require an entire part to be reprinted.

Why Should You Design for Manufacturing and Assembly?

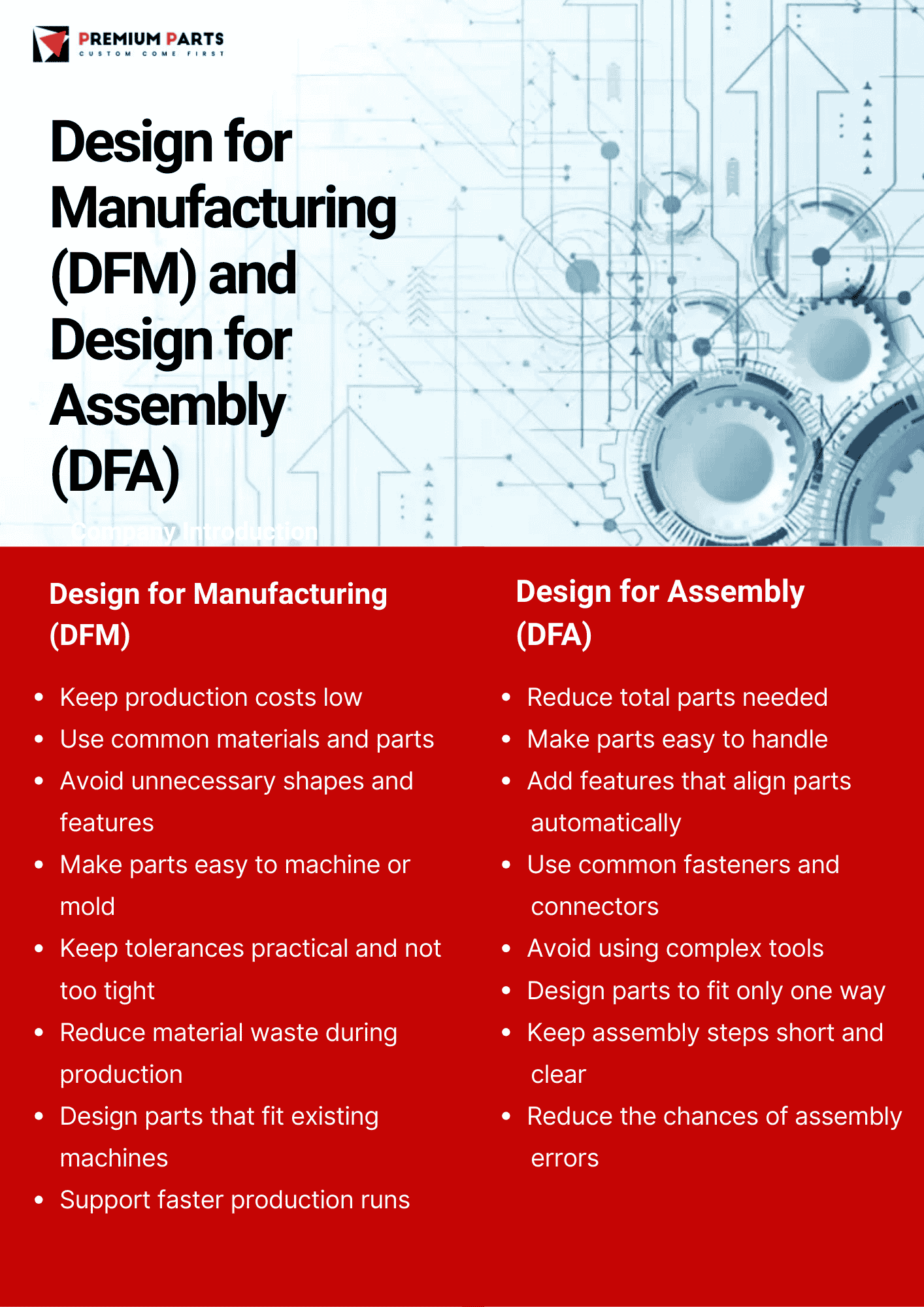

Design for Manufacturing (DFM) and Design for Assembly (DFA)

Design for Manufacturing (DFM) and Design for Assembly (DFA)

Image Description: The infographic compares Design for Manufacturing (DFM) and Design for Assembly (DFA), highlighting how DFM focuses on making products easier and cheaper to produce. In contrast, DFA focuses on making products simpler and quicker to assemble.

Cost-efficiency

For both start-ups and emerging businesses, being a cost-leader ultimately positions your company for profit maximization. Design for manufacturing means taking a standardized approach to design, which can cut about half of the manufacturing cost.

Manufacturing cost consists of process, material, and labor costs. When DFM is used, the chances of material waste are significantly reduced; there is a lesser need for labor for part assembly and process planning, and downtimes and setup times are also minimized.

Premium Parts Manufacturing Services in China

At Premium Parts, we offer product design and manufacturing services that are optimized for the production of many precision parts. Our expertise ranges across some services, and we can generate exceptional quality products with a quick turnaround. We can work with an extensive range of materials and produce both mass-manufactured volumes and low-volume manufacturing. From CNC machining to rapid injection molding, our engineers are highly experienced to deliver best-in-class manufacturing quality and standards.