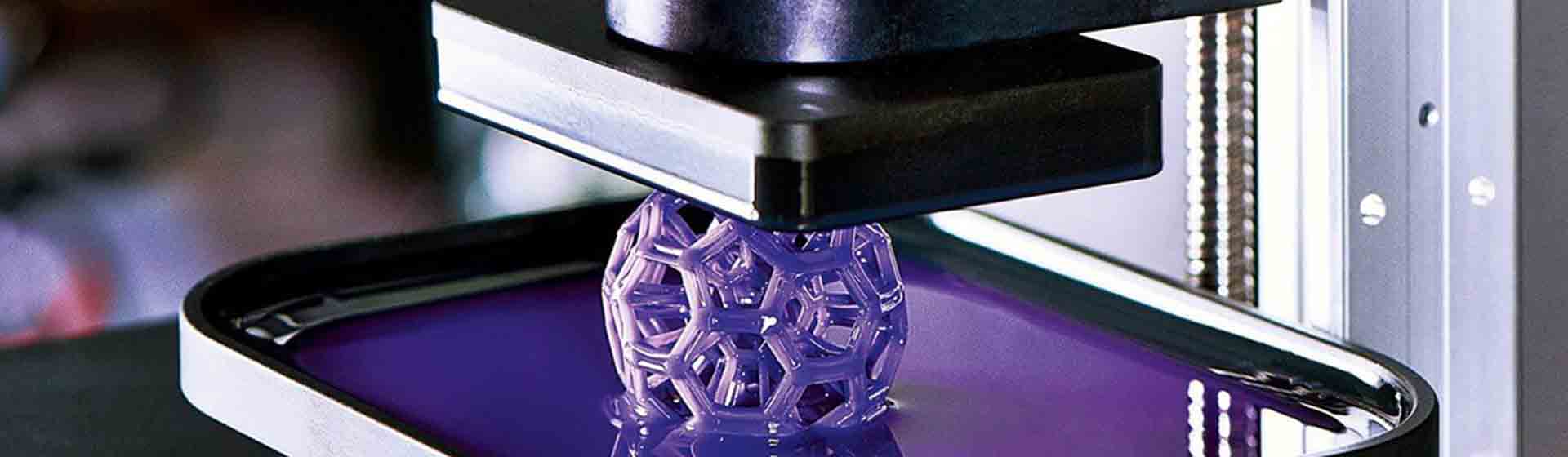

3D printed Plastic Fan Propeller

3D printed Plastic Fan Propeller

Image Description: Plastic fan propeller being 3D printed in a close-up view.

3D printing is frequently seen as a complement to CNC machining. Unlike CNC machining, which employs computerised instructions to subtract material until the final part is shaped, it constructs parts by progressively adding layers to form an item. It uses an additive manufacturing approach, while CNC machining is a form of subtractive manufacturing. Today, this has become a prevalent technique. This is chiefly due to its cost-savings, speed, and availability; 3D printers are widely available in both small and large sizes. They allow direct printing of a finished product straight from a computer model. And while it is doubtful to replace CNC machines and other traditional manufacturing methods, it may become a staple in most small and medium-sized businesses.

Rapid prototyping will greatly benefit from 3D printers, enabling product designers to make better selections when determining the most suitable manufacturing procedure for their needs. Understanding the advantages of 3D printing plays a crucial role in this decision-making process.

Top Benefits of 3D Printing

3D printing provides several advantages for manufacturing and product development. Manufacturers can minimise production time, lower material waste, and achieve complex designs that are hard to achieve with conventional machining methods. So, it is a notable option for both prototyping and full-scale production. Here are some of the common benefits of 3D Printing technology.

1. Speed

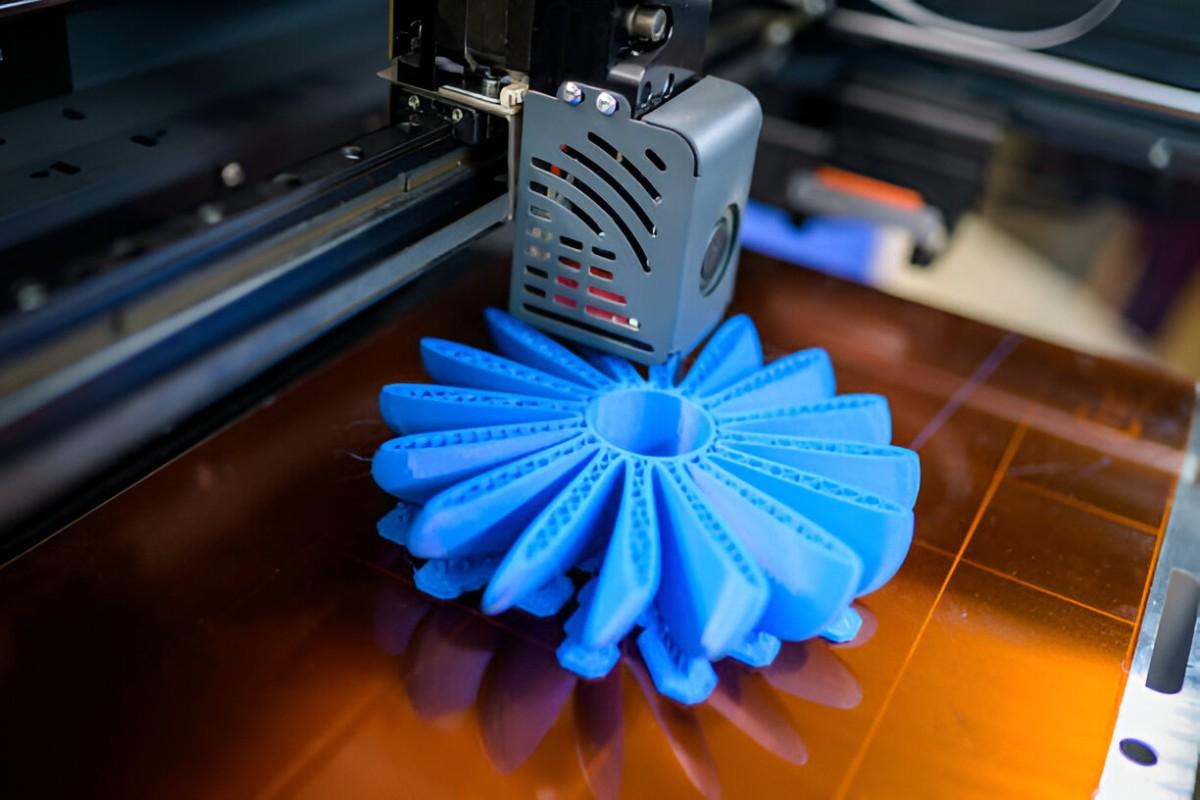

Complex 3D Printing Manufacturing

Complex 3D Printing Manufacturing

Image Description: High-speed 3D printing showing a completed design on display.

The speed at which additive manufacturing can produce end-use parts is often far superior to traditional machining techniques. In only a matter of hours, simply inputting a 3D CAD model can transform the product’s designs from ordinary digital models to real-life tangible products.

Where traditional machining will deliver a prototype in days or weeks at times, 3D prototype printing will deliver prototypes and physical iterations in hours. The extensive benefits of the speed of additive manufacturing are mostly felt when producing functional low-to mid-volume quantities. So, it offers reasonable time savings, allowing for rapid prototyping and design evaluation in hours.

2. Cost

Additive manufacturing techniques are generally more affordable than conventional machining and production processes. Production costs typically include materials, labour, and operational overheads. Because most 3D printers consume about the same energy as laptops, the operational cost for additive manufacturing is relatively lower. Furthermore, in most 3D printing jobs, assembly is unnecessary as the part is typically printed as a unified unit. This leads to a significant reduction in labour costs associated with assembly. When utilising 3D printers, the production process requires minimal labour. Apart from needing an expert to handle post-production tasks, 3D printing has minimal labour overhead compared to traditional machining, which usually relies on skilled machinists and experts.

For small and mid-scale production, 3D printing should remain the most cost-effective approach. However, as the volume increases, traditional machining emerges as the most cost-effective option in the long run.

3. Risk

Prototypes can be very costly to obtain, depending on what you plan to manufacture. Traditionally, prototypes will cost both time and money to produce. Conventional manufacturing necessitates the preparation of dies, tooling, and moulds, and even a slight deviation from specifications can result in significant and painstaking financial impacts. 3D printing helps to mitigate the risk of developing faulty prototypes and offers immediate hands-on design iteration and evaluation. We must emphasise the importance of being able to print prototypes and assess their suitability before proceeding with mass manufacturing. 3D printing is one of the most viable rapid prototyping and risk mitigation techniques.

4. Freedom to Design

From Design Concepts to the Final 3D Printed Product

From Design Concepts to the Final 3D Printed Product

Image Description: An illustration with arrows showing the process from design concepts to the final 3D printed product.

The limitations to 3D printing, such as minimum size features, are far less significant when compared to those around traditional machining. When using conventional methods, issues in producing parts with complex geometries often arise. Frequently, there would be complaints about shaping, tool access, draft angles, and undercuts. In 3D part printing, however, the final part is built from the ground up, layer by layer. This grants designers unrestricted freedom to create with the assurance that the final part will be achieved and output flawlessly. Complex geometries can be digitally designed and sent to a 3D printer for production without concerns about compromising functionality, aesthetics, or ergonomics.

5. Sustainability and Accessibility

3D printing and other additive manufacturing processes are highly sustainable and will minimise material waste to the barest minimum. While subtractive technologies such as CNC machining remove a part of the material to obtain the final part, 3D printing builds the part from the ground up. Therefore, it only utilises the exact amount of materials required for the part. Most additive manufacturing processes also reuse raw materials and recycle them to produce more than one build.

3D printers are also very widely available. After being around for 30 years, the technology has revolutionised, resulting in the availability of multiple models of 3D printers for purchase at diverse price ranges. Today, depending on the size and functionality, you too can own a 3D printer at a significantly lesser cost compared to owning traditional production equipment

6. Single-Step Manufacture

Product designers strive only to produce products with one part. One of the biggest advantages of 3D part printing is its one-step manufacturing. This enables the completion of manufacturing in a single operation, eliminating the need for part assembly. Once the design is finalised, the CAD file is sent to the 3D printer, which prints the final design within a few hours.

Single-step manufacture greatly trims costs and reduces the dependence on a number of manufacturing processes, such as welding or machining. In some cases, having a single product may guarantee that the final product is stronger than one that is welded or joined at numerous points.

Premium Parts 3D printing Services in China

Our 3D Printing Capabilities

Our 3D Printing Capabilities

Image Description: Screenshot of our service page highlighting our 3D printing capabilities and services offered.

At Premium Parts, we offer high-quality 3D printing services for many industries. Our expertise ranges across a number of services, and we can generate exceptional quality products with a quick turnaround. We can work with an extensive range of materials and produce both rapid prototyping and mass manufacturing volumes.