Are you looking for ways to enhance your product’s durability and improve its appearance? Reducing production costs while maintaining quality is undoubtedly a significant challenge. The two major issues product manufacturers face are ensuring the strength of binding components and enhancing production while reducing errors. Overmolding is an advanced manufacturing process in which one material is layered over another. It is a simple yet efficient method to eradicate all your production concerns.

With this process, you can integrate multiple components into a single unit without requiring additional assembly methods. However, this method is flexible and uses different materials. How does it work to offer high performance? To answer these questions, let’s analyze over-molding, its process, and its applications in-depth.

What is Overmolding?

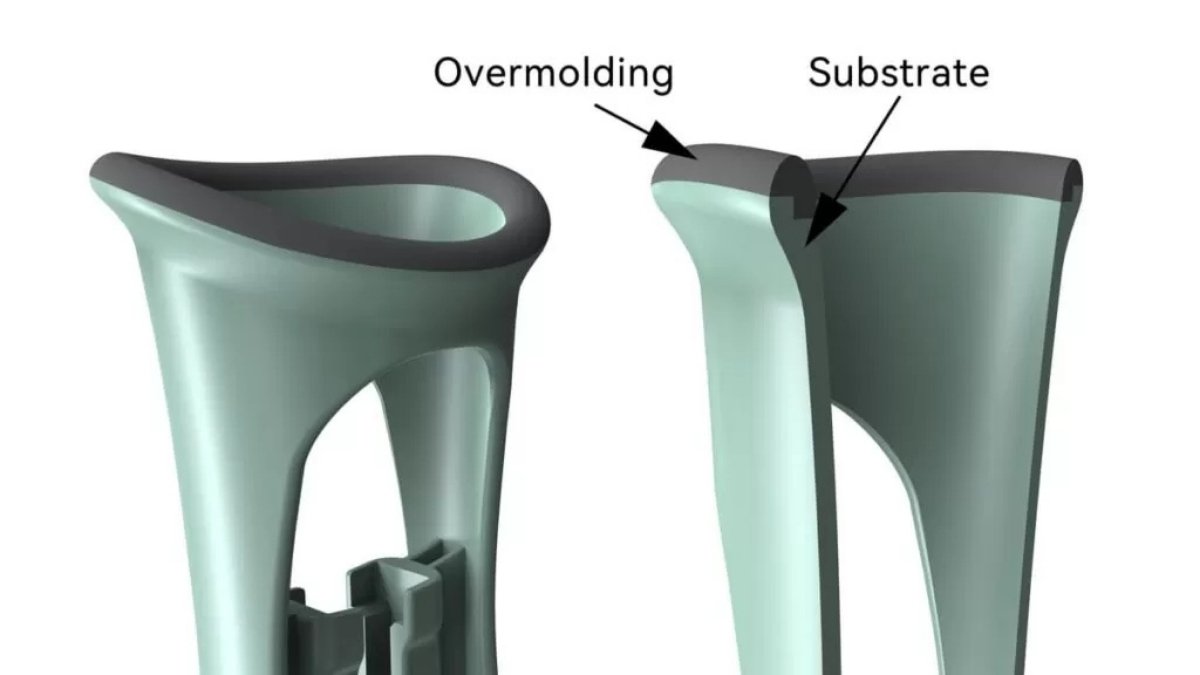

Overmolding

Image Description: The image illustrates an Overmolding example, illustrating a substrate with an overmolded layer.

Overmolding is an injection molding process that uses plastics to mold over other components. The plastics are usually thermoplastics and elastomers, which layer over the surface of another material. The two materials chemically fuse and form a single solid piece. For example, we can create a material with a rigid base, such as ABS, and a soft top, like rubber.

Although overmolding is an injection process, multiple iterations are needed to inject various materials. Generally, there are two types of over-molding:

- Direct Overmolding: First, we add a material to fill the molding space and allow it to cool. Subsequently, we add another material to form a layer on the first one and chemically bind it to it.

- Insert Overmolding: In the insert overmolding, you prepare a rigid part beforehand and then place it into the mold. The rest of the process is the same as direct over-molding.

How Does Overmolding Work?

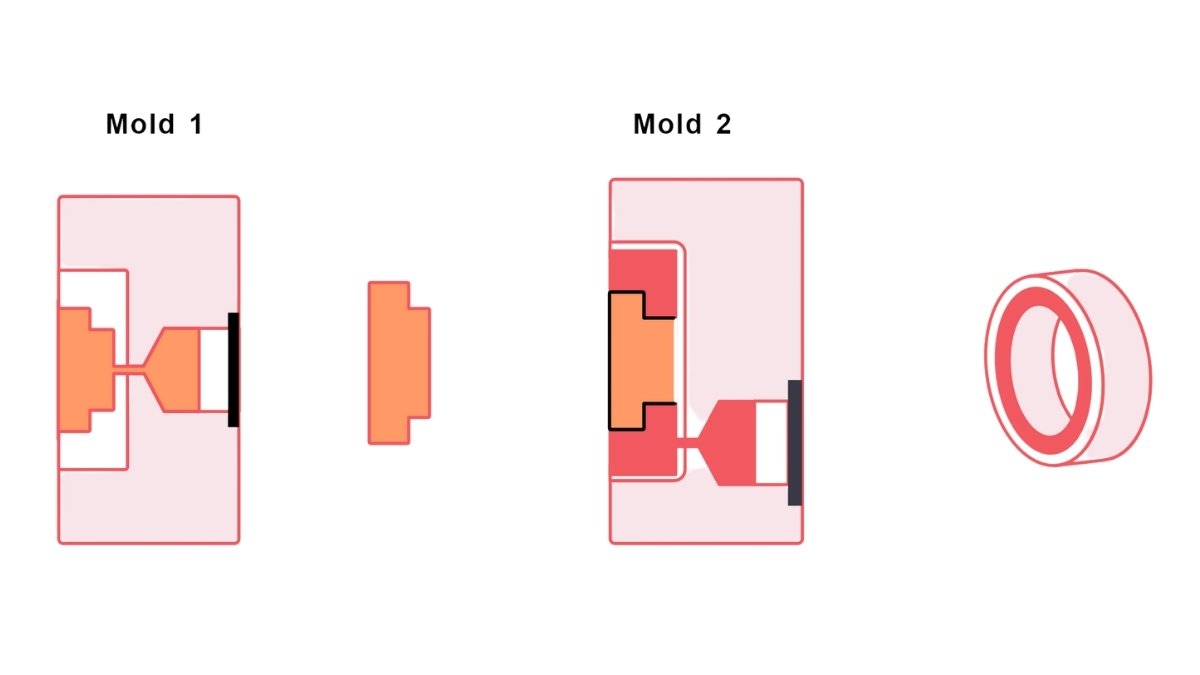

Overmolding Process

Image Description: The Image shows mold one forming the substrate, followed by mold two adding an overmold layer to create a single, stronger combined part.

Overmolding is not a lengthy process; you must follow it properly. It is not simple to select the material to place the injection molding part and then inject the other part over it. Here’s the step-by-step process of over-molding:

Step 01: Material Selection

The most crucial phase of over-molding is selecting the materials best suited for the product design and considering the product’s functionality. Of course, rubber can’t be used for a product that undergoes excessive wear and tear. Thus, understand the ergonomics and the product’s needs, such as thermal conductivity.

Step 02: Mold Design

Designing for over-molding is not easy. Start by understanding the functionality of your part during production. Additionally, consider whether the part will be exposed to UV, water, temperature, or other factors, as some components are prone to damage. Next, consider the part’s production needs. Thicker parts will need more time and material. Take vibration absorbers into account. TPE offers better vibration absorption when it’s thicker.

Step 03: Injection Molding Setup

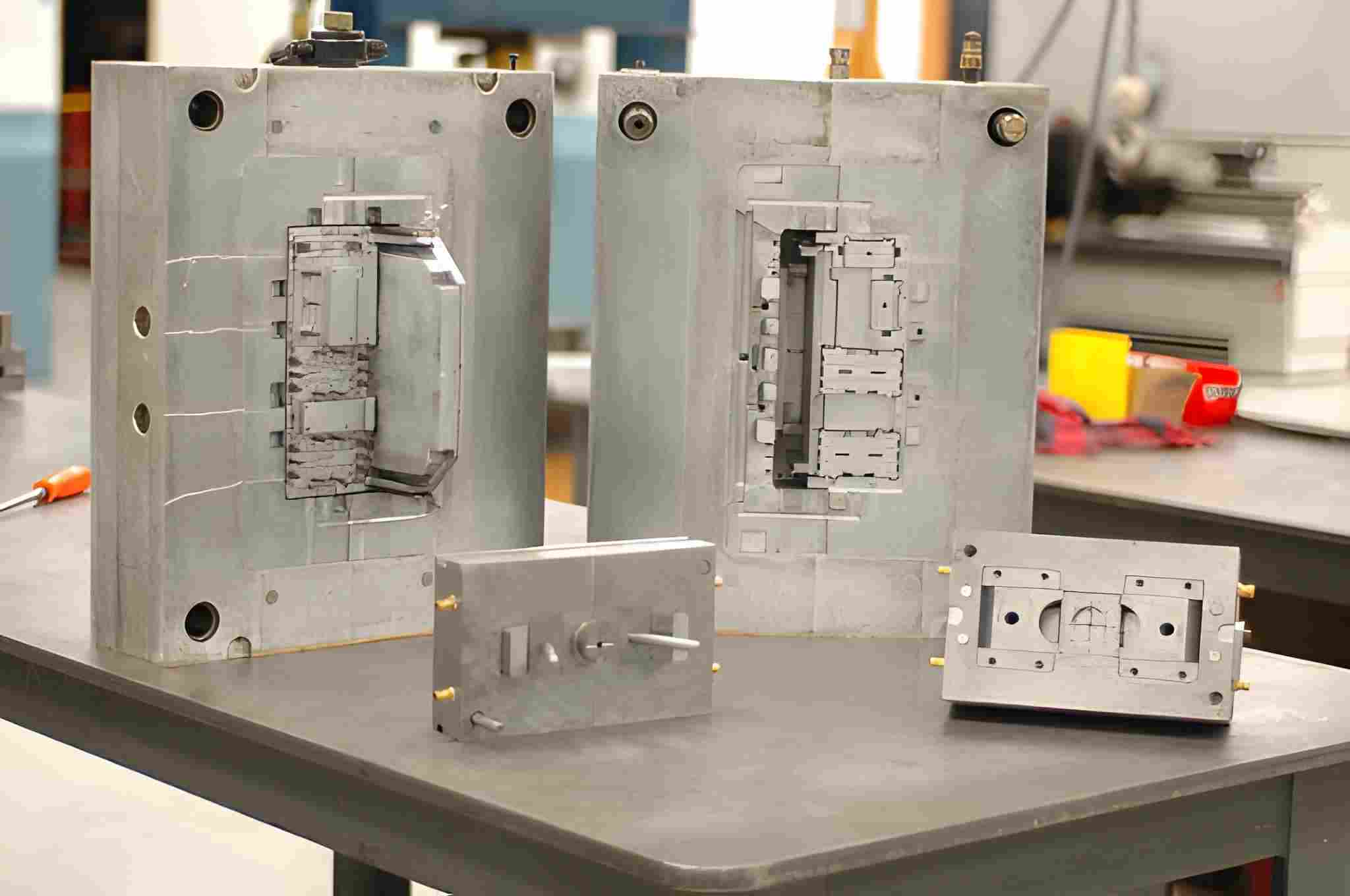

Precision Injection Mold

Precision Injection Mold

Image Description: Precision injection mold displayed on a work surface, showing clean cavities and sharp edges.

The injection molding setup is tailored to meet our specific needs and requirements. For example, if you are performing dual overmolding, you may require multiple injection molding setups. The setup can be rotated to accommodate the material precisely. Firstly, the unit places a base material, and after it cools down, we add another material.

Step 04: Ejection and Inspection

After the molding process, we remove the part from the mold. Subsequently, the operators scrutinize it for imperfections such as air pockets and bonding strength.

Step 05: Post Processing

After having a solid part made from a combination of different materials, we perform various post-processing steps on it. For example, we trim the material to remove excess edges or polish it to achieve a proper finish. These processes help enhance the product quality and aesthetics.

Design Tips for Overmolding

Designing the parts for overmolding is not easy. Therefore, we ensure the part design meets our requirements and aligns well with the overmolding process. You first need to understand the design process and function of the parts. Here are some significant points you need to consider:

Consider Material Properties

Understanding the material properties is essential, as designing parts according to their required functionality is critical. So, you need to consider which type of material it will feature. Record the capabilities of the material and its physical properties. Different materials have different melting points and expansion properties, so choose accordingly.

Moreover, in overmolding, we use different materials, so they should have different melting and expansion points. Some plastics may shrink off during the process. Thus, it’s best to use a substrate with a melting point higher than that of the other material.

Furthermore, the thickness of the material also makes a huge difference. A thick layer can absorb the vibrations and offer softness. However, a thin layer may melt down and feel more challenging.

Part Shape and Mold Optimization

The mold design should feature multiple injections with a 2 to 4 mm wall thickness. Moreover, the injection molding wall thickness should be even, and sharp edges and deep ribs should be eradicated. By doing so, there will be less stress, and the liquid material will flow easily. Generally, the edges of the molds should be less than 0.55 mm. The best practice is to measure with an angle of 1 degree through each inch for better ejection.

Bonding Enhancement

The two materials in overmolding should bond strongly together, as if they were a single object. They should blend at the chemical level and react to create a bond. Thus, the temperature you set is nearly the melting point of the materials. The materials melt down (not entirely, as the temperature is near the melting point) and react to form a bond.

In many cases, chemical bonding is not feasible, so a mechanical approach can be used. In that case, we use interlocks to bind the two materials together. Another standard option is to texture the materials so that the resin can fill the gaps between them.

Design for Manufacturability

You need to streamline the process from part production to part assembly. Assembly is also a more protracted process; one can minimize this by reducing the number of sub-parts. Additionally, you can utilize computer technology to refine the designs and streamline the manufacturing process. Computer analysis can detect material design shifts, leading to more substantial structures.

Moreover, the selection of the materials is a crucial aspect. Carefully choose the materials that fulfill the requirements and fill bond together. For example, if you need to create a power tool handle, the handle must be designed to provide support and softness from the inside to ensure a comfortable grip.

Do Some Post-Treatments

Ignoring post-processing might be a risk if you are in the manufacturing industry. To get the desired results, be ready to trim, polish, and paint. Moreover, you may need to perform additional treatments, such as UV and heat stabilization.

Types of Overmolding Materials

After understanding the material and part design, carefully select the material. There are multiple types of materials available for overmolding. So, you need to choose from them carefully. Subsequently, when you are familiar with the materials and their properties, you can make a more informed decision. And with that, we go directly to our suppliers and purchase the best materials according to our requirements. Here’s the list of materials we use in over-molding:

Thermoplastics

Thermoplastic Granules

Thermoplastic Granules

Image Description: Thermoplastic granules displayed in vibrant colors.

Thermoplastics have good melting points; therefore, they can melt under heat and harden up while cooling efficiently. Thus, they are the best option for melting and remodeling. Here are some of their popular options:

- Polycarbonate: This material is ideal for windows and protective gear due to its high resistance and optical clarity. However, it is prone to deterioration when exposed to UV light.

- Polyethylene: HDPE and LDPE variants are best for creating rigid to flexible parts. HDPE has high durability and strength; however, it is flammable. LDPE is flexible; however, it has a low melting point.

- Polypropylene: This is the best option for overmolding due to its high resistance and mechanical properties. It is generally used for consumer goods and automotive parts.

- ABS: ABS parts are versatile and have diverse applications across various industries. They have good heat capacity and offer a high-end surface. However, they are prone to deteriorating with chemicals.

Elastomers

Elastomers

Elastomers

Image Description: Elastomer materials are shown in flexible solid form, appearing smooth and slightly rubbery.

Elastomers, as the name suggests, are elastic and soft. Therefore, their best use is to make the soft layer over rigid products. The common types of elastomers best for overmolding are:

- Thermoplastic Polyurethane (TPU): TPU is a highly flexible, soft, and durable material. It is also resistant to scratches and rubbing. TPU binds well with plastics and is best for products that need a soft touch.

- Thermoplastic Elastomer (TPE): It features polymers with high elasticity and thermal properties. It is ideal for products that require a soft grip, such as spatulas, brushes, and other tools.

- Silicon Rubber: An ideal material for overmolding, offering flexibility, temperature resistance, and insulation. It binds well with different metals and plastics.

Applications of Overmolding

Overmolding is the best process to enhance the products’ design, style, and grip. Besides, it’s not costly. The combination of different materials increases the performance of products. Here are some significant applications:

- Consumer Electronics: This category encompasses overmolding for electrical covers, phone cases, and gaskets, providing durability, grip, and superior sealing.

- Automotive Industry: Feature over-molding of interior components in vehicles and their technological features for protection, weather resistance, and aesthetic appeal.

- Medical Devices: These include medical devices and tools for comfort, precision, safety, and functionality.

- Industrial Equipment: Tool handles and protective equipment include over-molding for better grip and mechanical protection.

- Consumer Goods: Includes household appliances and sports equipment for best usability and grip.

FAQs

1. What’s the difference between Co-molding and Overmolding?

Co-molding is a subcategory of overmolding with the same criteria and specs. It also needs compatible melting points and binding properties to mold different materials. Usually, there is a tricky part with a soft layer, such as rubber, over it.

2. What are the differences between Insert Molding and Overmolding?

Both are almost the same; however, the significant difference is in the setups. They both enable the molding of various parts and materials, thereby enhancing the quality and aesthetics of the part. Overmolding involves two steps: first, injecting the material, and then applying a second layer over it. Compared to insert molding, insert molding involves molding a pre-fabricated part onto a substrate.

3. What is 2K Molding?

In 2K molding (two-shot), we inject two different materials into the same mold. First, we inject the first material, which forms the base. Then, we rotated and adjusted its position to overlay the second material. This method can bind any plastic material by adding functional layers to the products.

Get the Overmolding Done with Premium Parts

At Premium Parts, we offer high-end overmolding services. If you require parts integrating different layers of materials with high-end finishes, Premium Parts is the right place for you. Whether you need overmolding of plastic over plastic or plastic over metal, we have something for you. We offer all combinations to offer the best and most affordable overmolding services. Our parts are precise, and we utilize cutting-edge technology to maintain a high pace and quality.

Thus, whether you need a few or many products, we ensure that they are delivered to you. Contact us now to receive a quote and expert guidance.