At the core of modern manufacturing is accuracy and efficiency; CNC Precision Machining plays an indispensable role here. Used from aerospace to medical devices, it has become an integral technology. But what is CNC Machining, how does it differ from traditional Machining, and why are precision CNC machines pivotal for producing top-quality CNC parts? In this comprehensive guide, we’ll discuss these questions in detail.

What Is CNC Precision Machining?

Precision Machining

Precision Machining

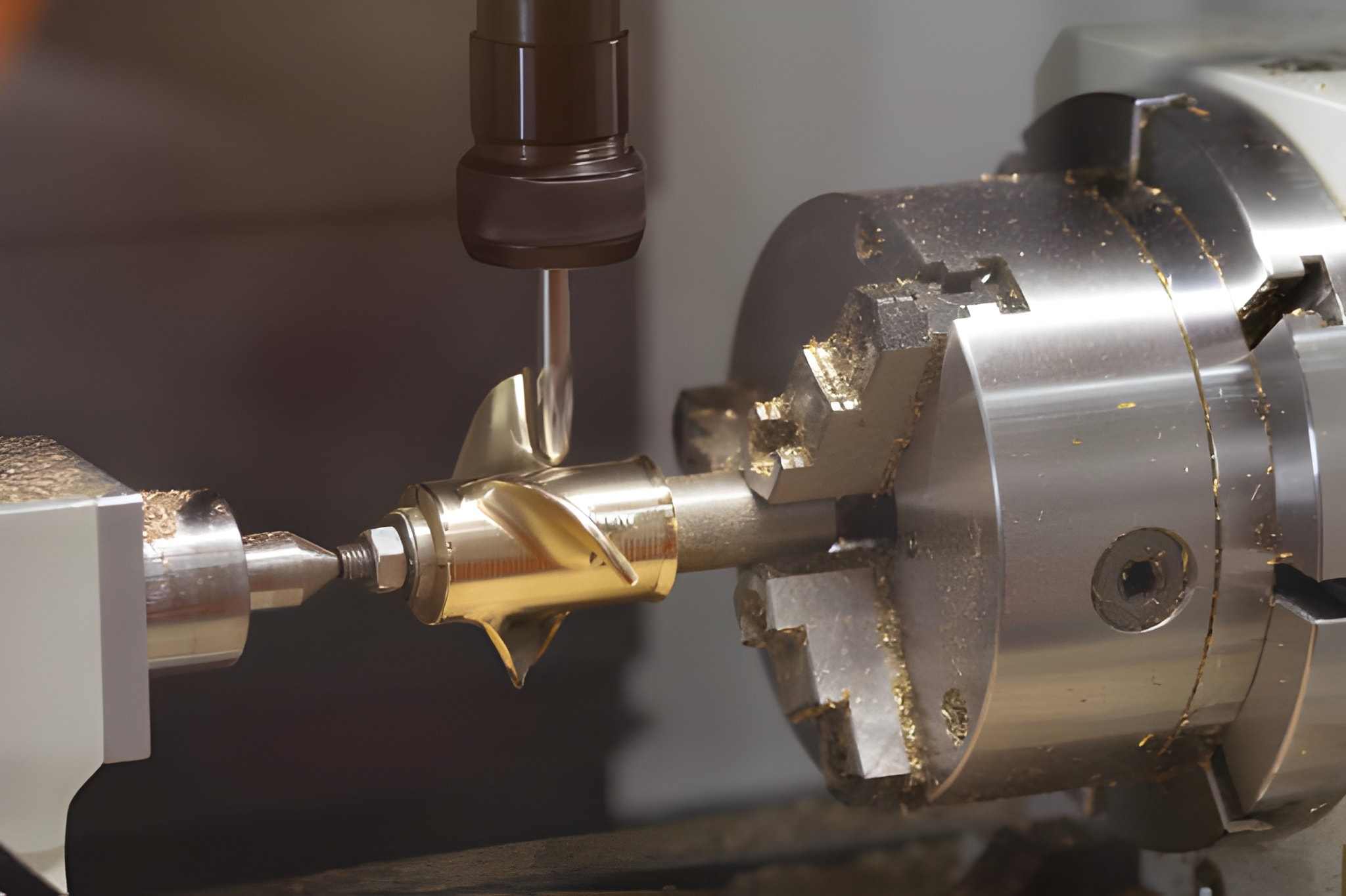

Image Description: A metal part being precisely machined on a CNC machine.

CNC Precision Machining stands for Computer Numerical Control Precision Machining. This advanced manufacturing technique employs computerized controls to precisely position tools and machinery, producing highly precise parts quickly and consistently. In contrast to traditional Machining, which relies heavily on manual operations, CNC Precision Machining utilizes automated machinery, resulting in higher precision, repeatability, and faster production times.

Key Components of CNC Precision Machining

CNC Machine Tooling

CNC Machine Tooling

Image Description: A CNC machine tooling setup with a part being machined.

To properly understand CNC precision machining, it is vitally important that one understands its core components:

- Computerized Controls: CNC machines use computerized controls as their central nervous system. Operators use CAD (Computer-Aided Design) software to input designs that will later communicate with CAM (Computer-Aided Manufacturing) software and form detailed instructions that guide their movements. Both communicate directly with each other for precise results.

- Precision CNC Machines: Machine tools such as lathes, mills, routers, and grinders are essential to cutting, shaping, and finishing raw materials. Equipped with tools designed for extreme accuracy, precision CNC machines can achieve tolerances as tight as micrometers – making them the ideal solution when accuracy is of the utmost importance.

- Tooling and Fixtures: CNC machining requires special-purpose tools and fixtures, including cutting instruments, to perform material shaping operations. In contrast, fixtures hold workpieces securely in place during machining processes to maintain stability and precision.

- Integration: It uses software integration to produce highly detailed and complex parts quickly and efficiently. Utilizing CAD/CAM software allows designers and producers to streamline the production processes more efficiently while producing complex parts quickly.

How Does CNC Precision Machining Work?

Engineering Part Design

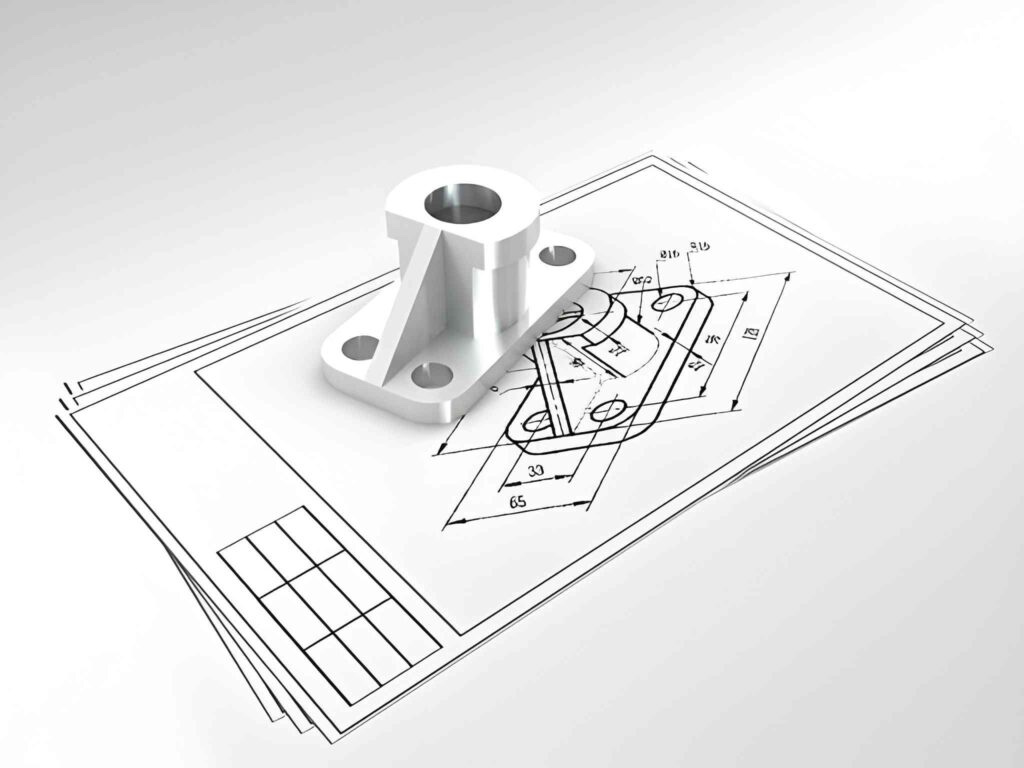

Image Description: A 3D CAD model showing an engineering part design with detailed geometry and dimensions.

It operates in an organized fashion, turning design specifications into physical components with extreme accuracy. Here’s a step-by-step overview of its processes:

- Design and Programming: Engineers begin the design phase by using CAD software to construct a 3D model of their desired part. After finishing this step, engineers convert this file to a CNC-compatible format before sending it off for plotting on CAM software, where paths for the machining tools will be marked out before being uploaded directly onto a CNC machine.

- Setup: Operators prepare their CNC machine by securing material, adjusting fixtures, selecting tools, and inputting specific instructions such as speed, feed rate, and cutting path parameters. An accurate setup ensures that every aspect of Machining meets design specifications.

- Machining Process: After everything has been assembled, the CNC machine begins cutting, shaping, or drilling material precisely along its programmed path with minimal human intervention required for the repetitive production of high-precision products. Thanks to its automated nature, it makes for repetitive high-precision production while remaining cost-effective and resourceful production methods.

- Quality Inspection: Once CNC parts have been machined, they undergo an in-depth quality inspection process to ensure each one satisfies design specifications and tolerances. With high-precision CNC machines available today, achieving consistent quality across large production batches is possible.

Advantages of CNC Precision Machining

It offers several distinct advantages over conventional manufacturing methods:

- High Precision and Accuracy: CNC Machining provides unprecedented levels of precision that would be almost impossible with manual machining techniques, making this form of production indispensable in industries where components must be assembled flawlessly – such as aerospace and medical device manufacturing.

- Consistency and Repetition: CNC machines offer consistent replications of identical parts with exact specifications every time, making them the ideal solution for mass production. Even with complex designs, CNC machining ensures each part remains similar to its predecessor in appearance.

- Efficiency and Speed: CNC machines make production faster by automating their machining processes. They operate nonstop without tiring out or experiencing fatigue, providing around-the-clock production if required.

- Reduced Human Error: CNC machines’ automation reduces human error significantly, with precision programming helping minimize mistakes for greater reliability in high-stakes manufacturing environments.

- Cost-Effective in Large Production Runs: CNC machining can incur higher initial setup costs; however, its precision and speed make it cost-effective over time, especially for large production runs.

Types of CNC Precision Machines

Precision Lathe Turning

Image Description: A precision CNC lathe machine turning a metal shaft with high accuracy.

It offers various machining requirements. Here are some of the more frequently used types:

- CNC Milling Machines: CNC milling machines use rotating cutting tools to remove material from workpieces. They are versatile machines often employed when producing complex parts with intricate details.

- CNC Lathes: CNC lathes are ideal for producing cylindrical parts, as their workpiece rotates while their cutting tool remains stationary. This type of machine is widely used for producing parts such as shafts and pipes.

- CNC Routers: CNC routers are widely recognized for effortlessly cutting soft materials such as wood, plastics, and aluminum to produce intricate shapes.

- CNC Grinders: CNC grinders are ideal for producing parts requiring an exceptionally smooth finish. They work by grinding down the material surface until the parts reach their desired shape and finish.

CNC Machining Materials

Aluminum Machined Parts

Image Description: Several aluminum machined parts with smooth surfaces and precise detailing placed together on a clean surface.

One of the many advantages of CNC Precision Machining is its versatility regarding material compatibility. Manufacturers can select different options depending on part requirements, each providing distinct advantages.

- Metals: Metals such as aluminum, steel, titanium, and copper are used due to their durability, strength, and versatility. Each metal boasts unique qualities; aluminum’s lightweight nature may appeal to some, while titanium offers strength and corrosion resistance, for example.

- Plastics: CNC machining of plastic materials such as acrylic, nylon, and polycarbonate is often employed in applications requiring lightweight yet corrosion-resistant parts for industries like automobile and medical device production.

- Carbon Fiber—Composites and Glass Fibre can both be machined for applications that require lightweight yet strong properties, such as aerospace and sporting goods manufacturing.

Application in Different Segments

- Aerospace: Precision is essential in aerospace to ensure safety and performance. CNC machining produces intricate parts for aircraft engines, landing gears, and other critical components.

- Medical Devices: Accuracy is of the utmost importance when it comes to medical equipment. CNC machining can be used to produce surgical instruments, implants, and orthopedic devices, for example.

- Automotive: CNC machining plays a pivotal role in producing engine and transmission parts necessary for reliable vehicles.

- Electronics: CNC machining can create compact and precise components such as housings, circuit boards and connectors for electronic devices.

Bottom Line

CNC Machining remains an invaluable resource in today’s highly competitive manufacturing environment. It enables companies to produce intricate parts with greater accuracy, consistency, and efficiency. Through its automated high-precision processes, CNC machining parts continue to transform industries from aerospace to medical devices.

Premium Parts Manufacturing Limited stands out as a pioneer in its field, specializing in producing top-grade CNC machining parts customized to the needs of various industries. Through our expertise in precision Machining, each component meets strict standards for accuracy, durability, and performance, making us your trusted source for precise CNC solutions.