Every machinist will testify that the soundness and performance of a CNC machine is imperative to achieving smooth operations in manufacturing. Every piece of equipment, regardless of its size, must be maintained to prevent part damage, downtime, and total equipment failure. To prolong the lifespan of your CNC machine, proper checks and servicing must be carried out on a timely basis.

When CNC machine operation is interrupted, the cost implications can be severe. Time-sensitive processes could become compromised, and fuel costs may yield a minimal return on investment. The cost of complete replacement can be prohibitive, and spare parts may not be in proximity. To mitigate operational risks and prevent breakdowns, it is essential to conduct regular maintenance, which not only saves costs but also keeps your machines in top shape. As is the case with everything in life, prevention is always better than a cure. Here’s a run-through of our quick tips for preventative CNC machine maintenance.

1. Schedule regular maintenance

CNC Machine Maintenance

CNC Machine Maintenance

Image Description: A factory engineer making a machine maintenance checklist in a manufacturing workshop.

One of the best preventive practices is to engage in regular, scheduled maintenance, regardless of the equipment’s condition. Rather than waiting for issues to arise with your machine, schedule periodic check-ups based on your equipment’s usage pattern. You may opt to do general maintenance every 90 days or after every 5,000 units of a product have been manufactured.

Regular maintenance exercises will help to detect potential or developing issues and ensure that your machine is always running at its optimal capacity.

2. Use an employee-check system

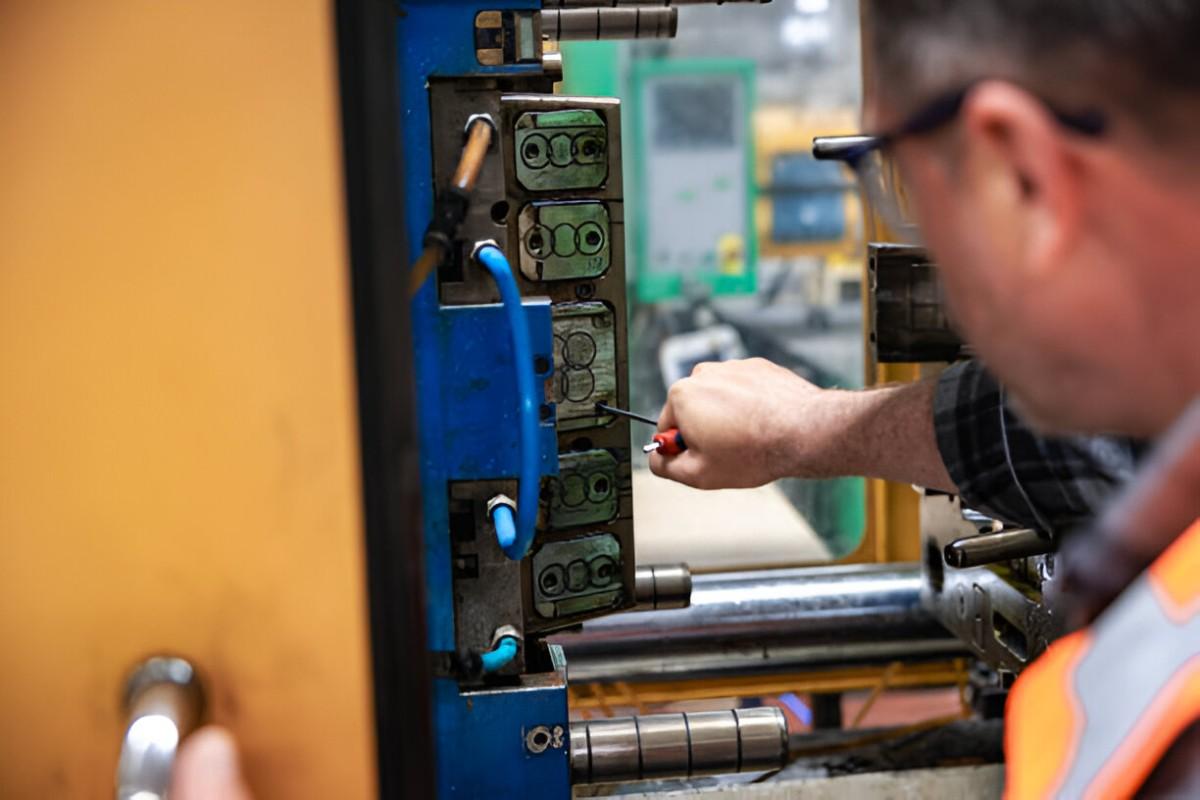

Male Worker Repairing CNC Machine

Male Worker Repairing CNC Machine

Image Description: Close-Up of Male Worker Repairing CNC Machine with L Shape Square Head Wrench in Manufacturing

Even with their high levels of automation, CNC machines still require human interaction in certain situations. Because work is most likely to be done across departments, you should establish an employee-check system that makes the machine operator most responsible for evaluating the soundness and performance of the equipment.

Aside from holding people responsible for maintenance, the employee-check system allows you to quickly identify potential issues, as the operator assigned to the equipment is better equipped to understand the machine’s condition and performance. This also means that they will be able to gauge variations in performance and identify problems more quickly.

3. Lubricate frequently

Machines, both large and small, consist of various moving parts, including the engine, gears, handles, and axles. These parts often generate a frictional force that leads to gradual wear and tear. To control this wear and tear, CNC machines require proper and generous greasing to slow down depreciation and heat accumulation.

CNC machines are also reliant on hydraulic fluids and coolants for effective performance. Refer to your machine’s manuals to determine the optimal oils, greases, and fluids for maintaining smooth operation. Also, keep track of the rate of fluid consumption of your device as fast-drying fluids and lubricants are often attributable to high operational temperatures, weather or most likely, engine problems.

4. Clean your equipment

CNC Machine Cleaning

CNC Machine Cleaning

Image Description: An operator blowing impurity after a CNC machining operation.

Equipment cleaning should be done daily in every machine shop. Ensure that you clean the chips out of the pan after production and wipe down any stains on your machine part to prevent permanent spots.

For door windows and lighting, ensure that you wipe down with a clean, smooth cloth to keep the inside of your machine visible. The lower parts of machines are often hubs for spiders; do a broom sweep to remove any cobwebs present.

Every 40 hours, clean off the air filter in your CNC control cabinet and coolant tanks. Drain spent oils and lubricants every 150 hours and remove the jaws and chuck of your machine to remove stuck bits of material parts.

5. Know how to replace old equipment

No matter how well you’ve maintained a piece of equipment, it will come to the end of its lifespan. Most machine shop owners are typically averse to retiring or replacing old equipment in their workshops. For some people, it’s a matter of sentiment; for others, they seem to believe they haven’t gotten enough out of the equipment. Whatever the case may be, every machine will eventually require more maintenance as it approaches the end of its life. The best practice is to depreciate your machinery over a period and dispose of it when you can salvage a reasonable amount from it. The proceeds from the sale should then be invested in another, newer, and more sophisticated piece of machinery. This way, not only do you stay up to date with the latest technology, but you are also able to avoid frequent breakdowns and hedge your risk of keeping obsolete equipment for too long.

6. Avoiding costly downtimes

The average manufacturing business tends to focus on reactive maintenance rather than preventative action. This often results in costly downtime that delays client jobs and erodes customer trust. This is why your CNC machine must remain well-maintained and serviced regularly.

At Premium Parts, our manufacturing equipment is top-of-the-shelf, best-in-class, enabling us to deliver production parts more quickly, efficiently, and reactively. If you don’t have a CNC shop of your own and are looking to run a prototype or low-volume production for your new or existing project, we invite you to partner with us.