3D Prototype Printing

3D Prototype Printing

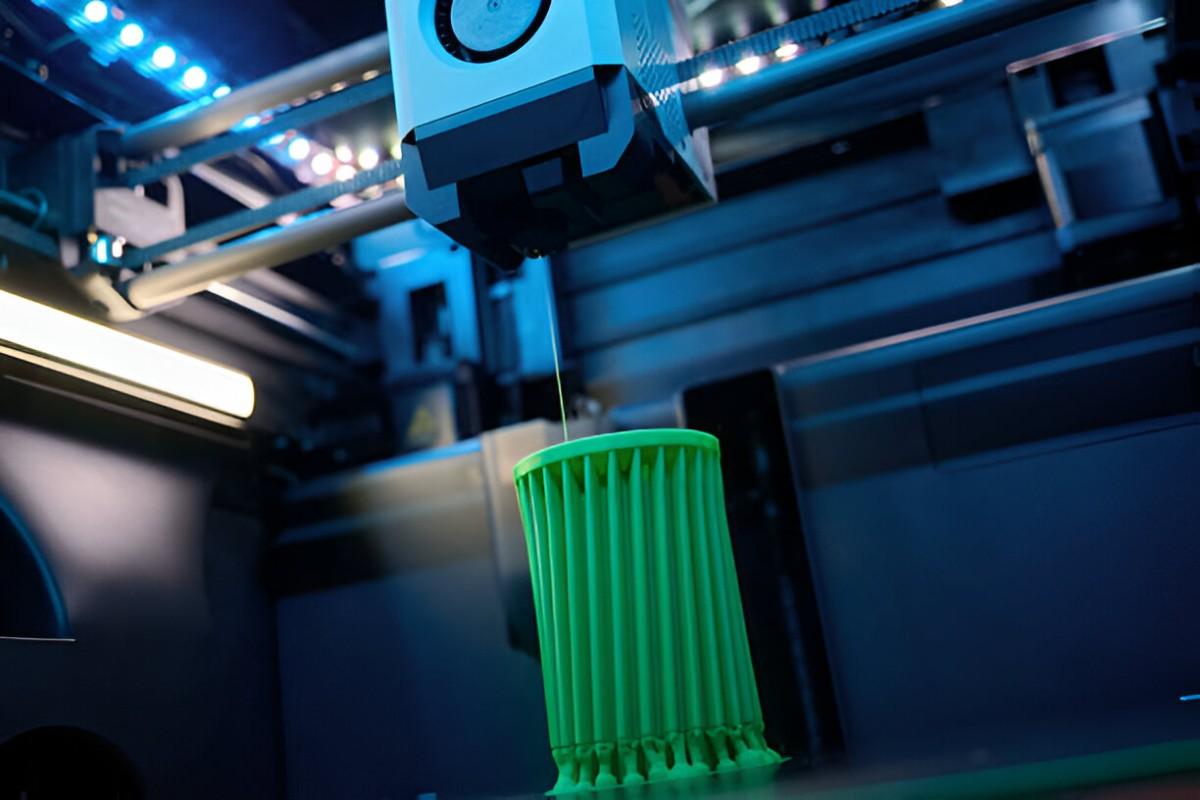

Image Description: Image showing a 3D printing process where a prototype part is being built layer by layer.

Manufacturing often faces delays, high expenses, and design limits. Producing prototypes and customised parts with traditional methods can be slow and costly. 3D printing overcomes these issues. It is an additive manufacturing process that builds parts layer by layer from digital models. Unlike subtractive manufacturing methods like CNC milling and turning, it uses only the material required to form the part. This process reduces waste and allows greater design freedom.

The process starts with a CAD model. The specialised software interprets this design into thin layers. The printer follows these layers, adding and solidifying material step by step. 3D printing supports various material options. The most common material choices include PLA, ABS, resins, metals, and composites. Each requires specific print settings and thermal control to achieve accuracy and strength.

When it comes to applications, 3D printing is used for prototypes, functional parts, and custom products. It allows design engineers to test designs quickly and build complex shapes with relative ease. This guide provides a complete overview of 3D printing technology. So, keep reading.

The 3D Printing Process

3D Printing Process

3D Printing Process

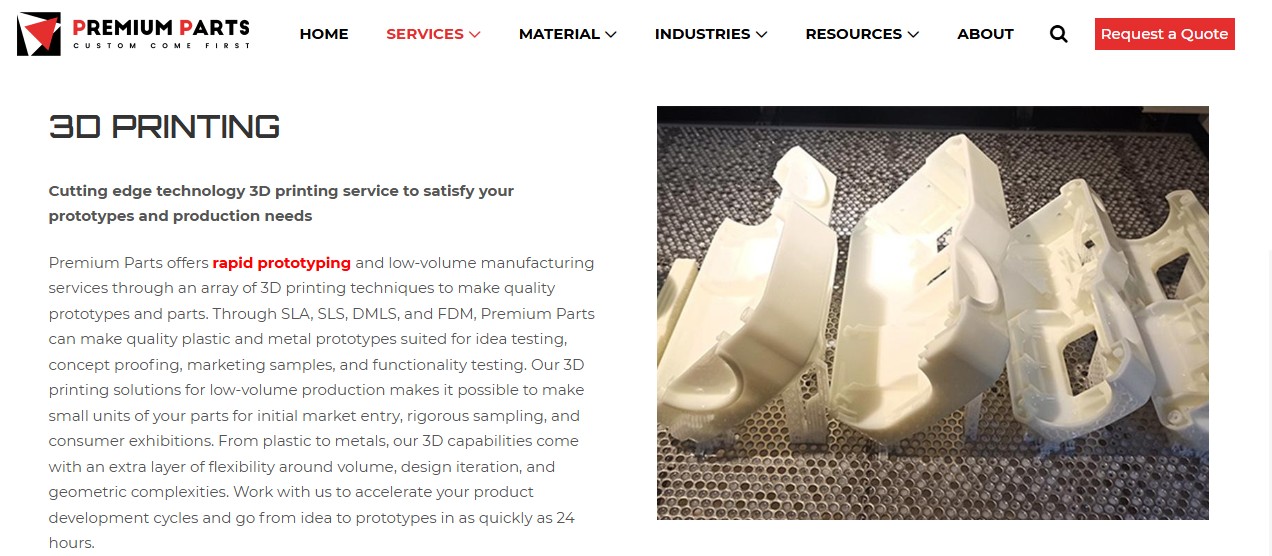

Image Description: A green product being made in a 3D printing process.

In this section, let’s take a look at how 3D printing works. You will see the main steps from design to post-processing.

Step 1: Design the CAD Model

Every print begins with a digital design. Engineers use CAD software to create a 3D model of the part. The design must be accurate because even minor errors will affect the final print. At this stage, you can refine geometry, test tolerances, and adjust dimensions before production.

Step 2: Convert to STL File

The model is then exported into an STL file. This format represents the surface of the design with small triangles. A finer mesh gives smoother results but also creates larger file sizes. STL is the standard format because it works with almost every slicing program.

Step 3: Slice the Model

Slicing software prepares the STL file for printing. It cuts the model into thin layers and generates the toolpath instructions. These instructions, known as G-code, tell the printer how to move, where to deposit material, and when to build supports. Settings such as layer height, infill, and speed are defined here.

Step 4: Prepare the Printer

The chosen material is loaded into the machine. The printer is calibrated by setting the nozzle temperature, bed temperature, and alignment. Each material has its requirements. For example, PLA prints easily at low heat. ABS needs higher temperatures and a heated bed. Proper setup prevents issues like warping and poor adhesion.

Step 5: Printing the Part

The printing process builds the object layer by layer. In filament printing, melted plastic is extruded through a nozzle and cools into shape. In resin printing, light hardens liquid resin into solid layers. Regardless of the method, precision control ensures that each layer bonds correctly with the next.

Step 6: Post-Processing

After printing, the part is removed from the build platform. Supports are carefully taken off, and the surface may be sanded, polished, or smoothed. Some materials require curing or heat treatment to increase strength.

Choosing the Right Material between PLA Vs ABS

Colourful plastic PLA and ABS spools with filament

Colourful plastic PLA and ABS spools with filament

Image Description: Side view of colourful plastic spools of PLA and ABS filament used for 3D printing.

Polylactide (PLA) and Acrylonitrile butadiene styrene (ABS) are two of the most widely used filaments in 3D printing. These two materials have some properties in common, but are not entirely the same.

PLA has more applications than ABS in 3D printing. It is an inexpensive, biodegradable print material used in the production of showcase models and rapid prototypes. ABS, on the other hand, is a sturdier plastic than PLA. ABS has excellent mechanical properties that make it suitable for gears, fixtures, casings, and consumer electronics. Let’s take a deeper dive into these two materials and help you find out which is best for your 3D printing project.

• Strength and Durability

Acrylonitrile butadiene styrene (ABS) is generally more durable and stronger than Polylactide (PLA). Several mechanical tests have shown that ABS is more rigid, more stress-resistant, and more impact-resistant than its PLA counterpart; because of this, PLA is less likely to be used for projects that interact with high stress, repeated usage, and those that are impact-prone.

• Environmental Impact and Safety

PLA is more environmentally friendly and less toxic to print compared to ABS. ABS’s toxicity is well known in 3D printing as the material may emit some harmful fumes. This is why one should never remain in a room where ABS is the 3D printing material for too long.

ABS also has a more pungent odour relative to PLA, and while PLA can also be harmful, proper ventilation of the room will significantly limit its impact. ABS is non-biodegradable, while PLA is semi-biodegradable and compostable, as it consists of some natural constituents in its makeup.

• Cost

Both ABS and PLA materials cost around the same price per KG. No significant cost savings are arising from using one material over the other. However, if a cheap 3D printer is what is at your disposal, opting for PLA will make your life significantly easier.

• Applications

ABS is the preferred option for printing materials for those products that are more likely to face more stress. ABS is also far more resistant to the elements of nature and chemical compounds, making it the preferred option for models that will have a higher rate of wear and tear. PLA is less pressure and heat-resistant than ABS. It is more suitable for prototypes and exhibition items, and comes in a wide variety of colours

• Ease of Printing

PLA is relatively more straightforward to print when compared to ABS. This is because PLA does not require high temperature conditions and does not need to be enclosed to print. PLA also poses a less arduous task of working with nozzle temperatures, melting around 338°F, with no need for any heated tables, although it would be far easier if you had one. PLA is better suited for making 3D prints like bridges and overhangs, where you do not want to use a support.

ABS is more sensitive to temperature changes while printing. This may mean more problems with warping when printing 3D projects.

Bottom Line – ABS or PLA?

Now that we’ve had a look at the properties of both materials, you can decide on what is better suited for your project. ABS is more durable and stronger, which makes it better for applications where the part is more likely to experience wear and tear. It will make sturdier materials, but if toxicity is a concern for you, PLA is a better alternative. ABS will also require an enclosed printing condition under high pressure and temperature, limiting the type of printers that can be used with this filament.

PLA, on the other hand, is excellent for quick prints and on-the-go showcase models. It offers more colour options, and its low-temperature demands mean it would run on a low-cost 3D printer. Both filaments cost around the same thing per KG; however, the PLA material will be relatively more straightforward to print jobs where strength and durability aren’t a significant concern.

3D Printing at Premium Parts

Premium Parts offers a professional 3D printing service for making a wide array of product parts. At Premium Parts, we have numerous printing technologies available for use with many high-grade printing materials and filaments. Our excellent quality control systems ensure that all our deliveries are speedy and standard for every size of manufacturing.