Burrs are one of the common defects that may be experienced when dealing with aluminum extrusions. They occur as rough ridges or edges on the aluminum profile caused by processing operations like milling, drilling, engraving, punching, turning, laser/plasma cutting, blanking, or shearing. Burrs may also form due to operator handling or machinery configuration as well as the material thickness and grade.

Unlike other aluminum processing defects, surface burrs are more difficult to find without detailed observation with the hands and the sense of touch. Burrs impact the aluminum profile negatively as they lower the surface quality of the profile after oxidation and electrophoresis. For top manufacturing shops with significant investment in sheet metal manufacturing and aluminum extrusion, it is important to understand the causes of burrs and how to take timely measures that will help to minimize or eliminate the chances of these defects.

1. How Burrs Form

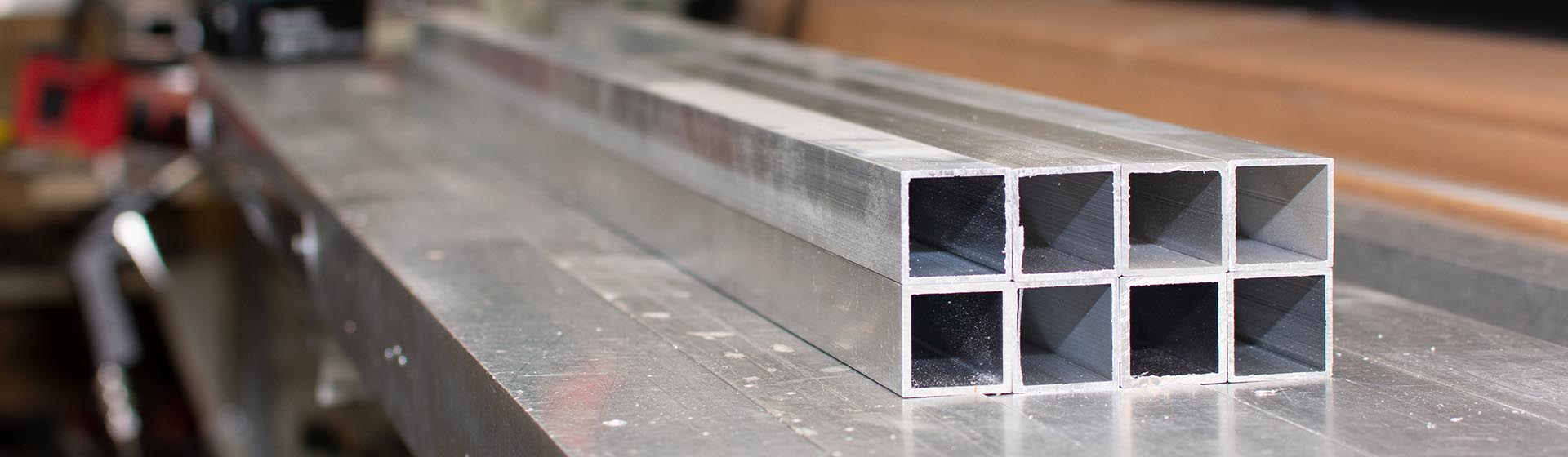

Burr formation on the Aluminum Extrusion Profile

Image Description: The image shows an aluminum extrusion profile with visible burr formation along its edges and surface.

Burrs may be formed during different processing stages and phases. It may occur due to the material selected or may arise as a result of the aluminum extrusion die. Some of the causes of burr formation include:

1. Elastic deformation of the die

2. Inappropriate selections of aluminum extrusion parameters

3. Shallow die empty tool positions

4. The impact of molds

5. The Cast bar quality

2. Avoiding Burrs in Aluminum Extrusion

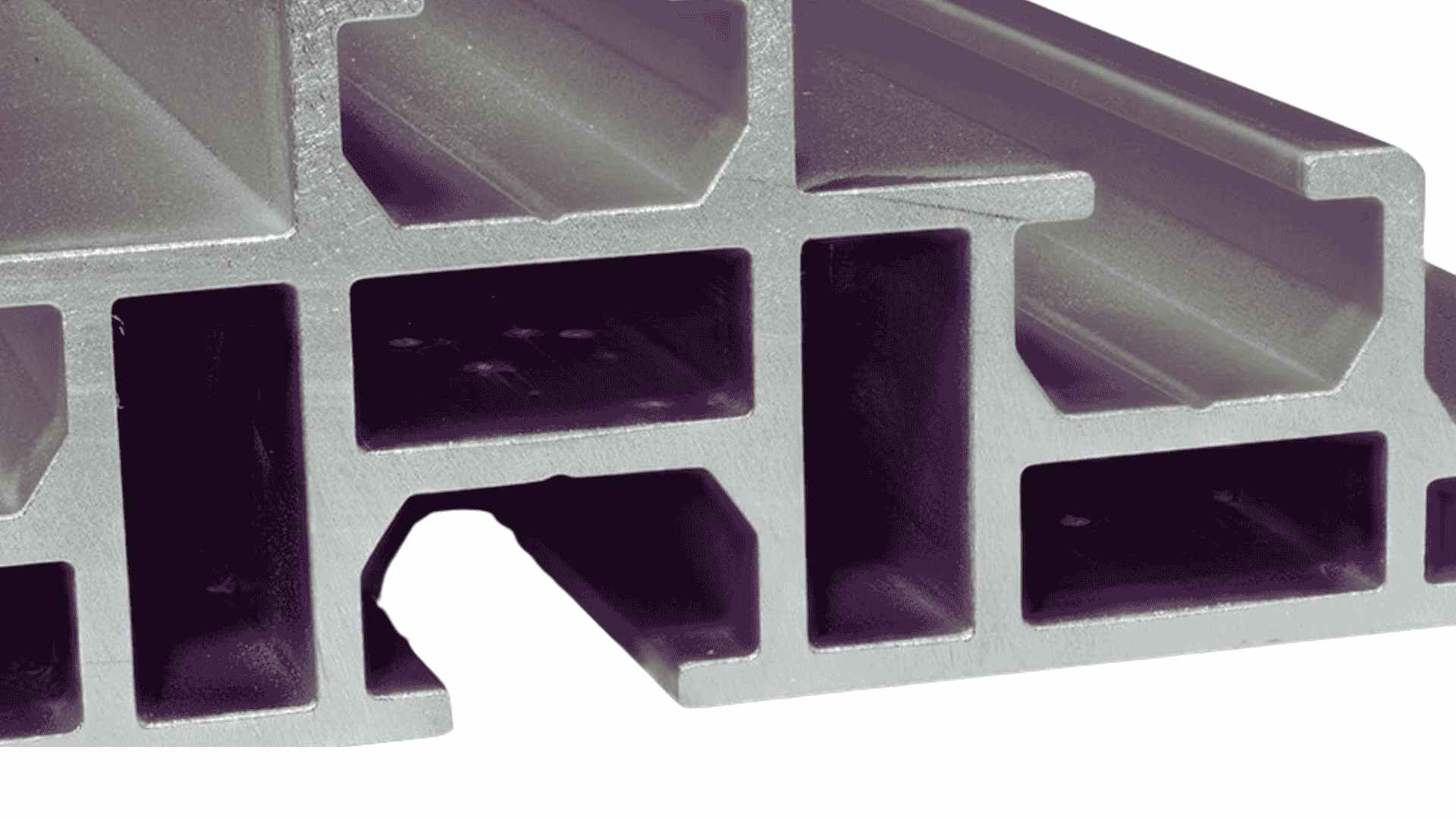

Aluminum Extrusion Profile

Image Description: A Showcase of two aluminum extrusion profiles.

Since we now have an understanding of the most common causes of burr formation, the following measures may be employed to avoid burrs and other common defects in aluminum extrusion:

- Design the Die to Minimize Elastic Deformation: Reduce the chances of elastic deformation of the die under compression by ensuring that the design of the die is in tandem with the strength and stiffness conditions under which it might be exposed.

- Avoid Sharp Angles in Mold Design: Avoid sharp angles that may result from the mold production by considering all appropriate parameters in both design and processing.

Thread Cutting and Burr Removal Using a Vise and Taps

Image Description: The image shows a workpiece held securely in a vise while a tap is used to cut internal threads.

- Inspect Mold Condition Before Use: Ensure that the mold to be used is in decent condition. Check on the cleanliness, the shape of the mold, and even the appropriate use of shear or die pads.

- Perform Nitridation Treatment on Molds: Perform mold treatment exercises by nitridation before placing them in the machine for production.

- Maintain Ideal Die Conditions During Manufacturing: Ensure that the die is also in ideal conditions for manufacturing. Pay attention to temperature, pressure, bolt speed, tightening, surface roughness, and the entire die assembly.

- Enhance Cast Bar Quality Through Quality Control: Improve the cast bar quality by adopting effective technical measures to avoid defects such as porosity, coarse grain, or slag inclusion through strengthened quality control measures.

- Improve Environmental Conditions in the Processing Area: Improve the environmental conditions of the processing area by cleaning the cast bar surface, using high-pressure air to blow away dust, cleaning the die and molds, cleaning the aluminum profile, avoiding oil particles and “run drip leakages” as well as other factors that can promote impurities and dust materials in the area as much as possible.

- Control Extrusion Parameters for Optimal Results: Carry out the aluminum extrusion process with the appropriate processing parameters. Monitor the profile section, the die, mold, equipment, extrusion coefficient, extrusion temperature, die speed, extrusion speed, cast bar heating temperature, and other parameters that will reduce or eliminate the chances of having adsorbed particles

Premium Parts’ Aluminum Extrusion Service In China

Premium Parts provides aluminum extrusion for a wide array of applications in China. Our in-house capacity can deliver on quality, avoid defects like burrs, flashes, and facilitate low-volume manufacturing at affordable rates. If Aluminum extrusion is one of the services, you’re looking to secure in manufacturing your parts, please contact us to get a free quote from our expert engineers and design inspection to get started on your project.