Washers are fastening elements. They are made of resilient metals. Typically, they come in numerous shapes, types, and sizes. Each type serves a unique purpose. For example, flat washers help distribute the load of a fastener uniformly. Besides, it prevents the material from being damaged by high pressure. These are used in wood, metal, and plastic applications for added stability.

Likewise, spring washers increase the tension. Additionally, they help prevent fasteners from loosening due to vibrational forces. However, both types of washers are essential for creating durable and long-lasting assemblies. Let’s get into the details of the types of washers, sizes, and typical standards they adhere to.

What is a Washer?

Spindle Washers

Spindle Washers

Image Description: In this image, various sizes of spindle washers are displayed, showing their uniform thickness and circular design.

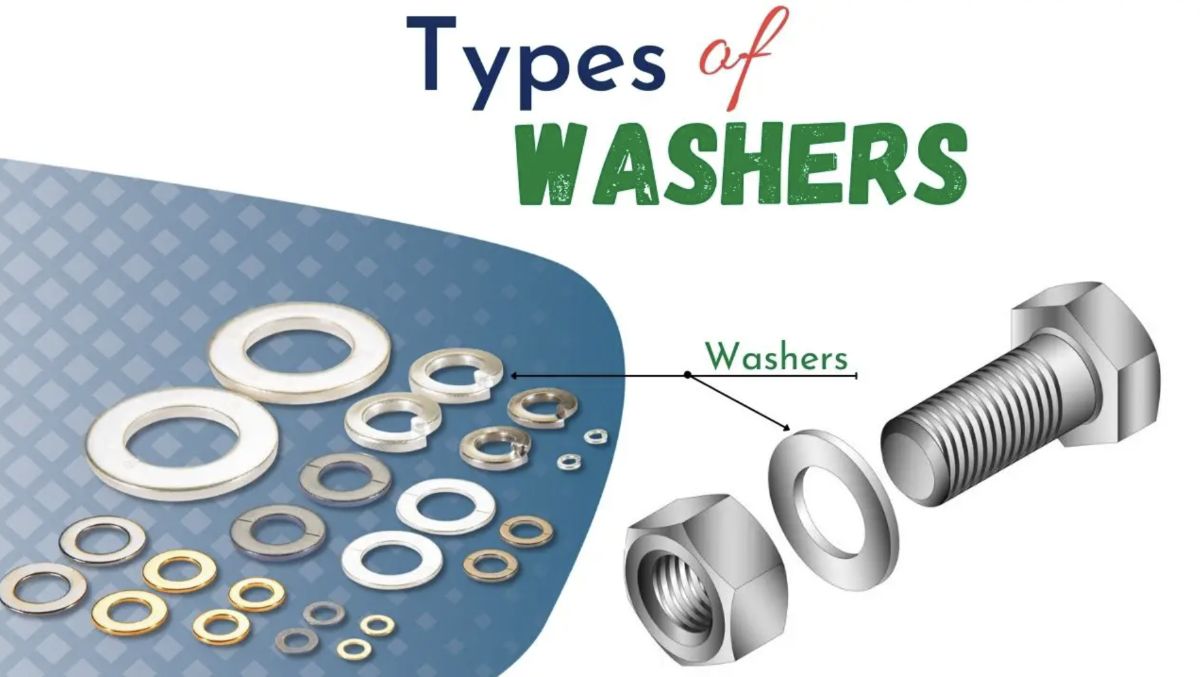

A washer is a thin, flat disc. Primarily, it is used in mechanical assemblies and couplings. It is placed between a fastener, like a bolt or nut, and the surface to prevent loosening. Depending on the applications, washers are made of various materials like steel, stainless steel, or plastic.

Technically, washers are employed to distribute the load of a fastener evenly over a larger area. So, it helps to reduce the risk of surface damage and provides a tight and secure fit.

What Is the Purpose of a Washer?

Uniform Load Distribution

A washer assists in distributing the load applied to a fastener. It uniformly spreads the pressure over the material, thus stopping damage from crowding itself into a limited area. This way, the connection is much more secure and stable as compared to a simple random connection.

Prevents Surface Damage

Different types of washers serve the purpose of absorbing the tension between the fastener and the surface. These shield the material of the assembly from being sacrificed, bent, or compressed by the fastener, which can be made of wood, metal, or plastic.

Prevents Loosening

Certain washers, such as spring washers, prevent fasteners from loosening. They apply tension to resist vibrations or movements that can cause the fastener to become loose over time. This keeps your assembly secure in high-vibration environments.

Improves Assembly Tightness

Washers provide an extra layer of support that enhances the tightness of a connection. With a washer in place, fasteners grip more securely, reducing the chances of bolts or nuts coming loose under pressure.

Increases Longevity

Washers help extend the lifespan of both fasteners and materials. They reduce wear and tear by minimizing friction and preventing direct contact between metal parts. This contributes to long-term durability, even under heavy usage or stress.

What Are The Different Types of Washers?

Common Types of Washers

Common Types of Washers

Image Description: This image illustrates different washer profiles with labels showing their functional differences, such as ‘vibration resistance’ and ‘load distribution’.

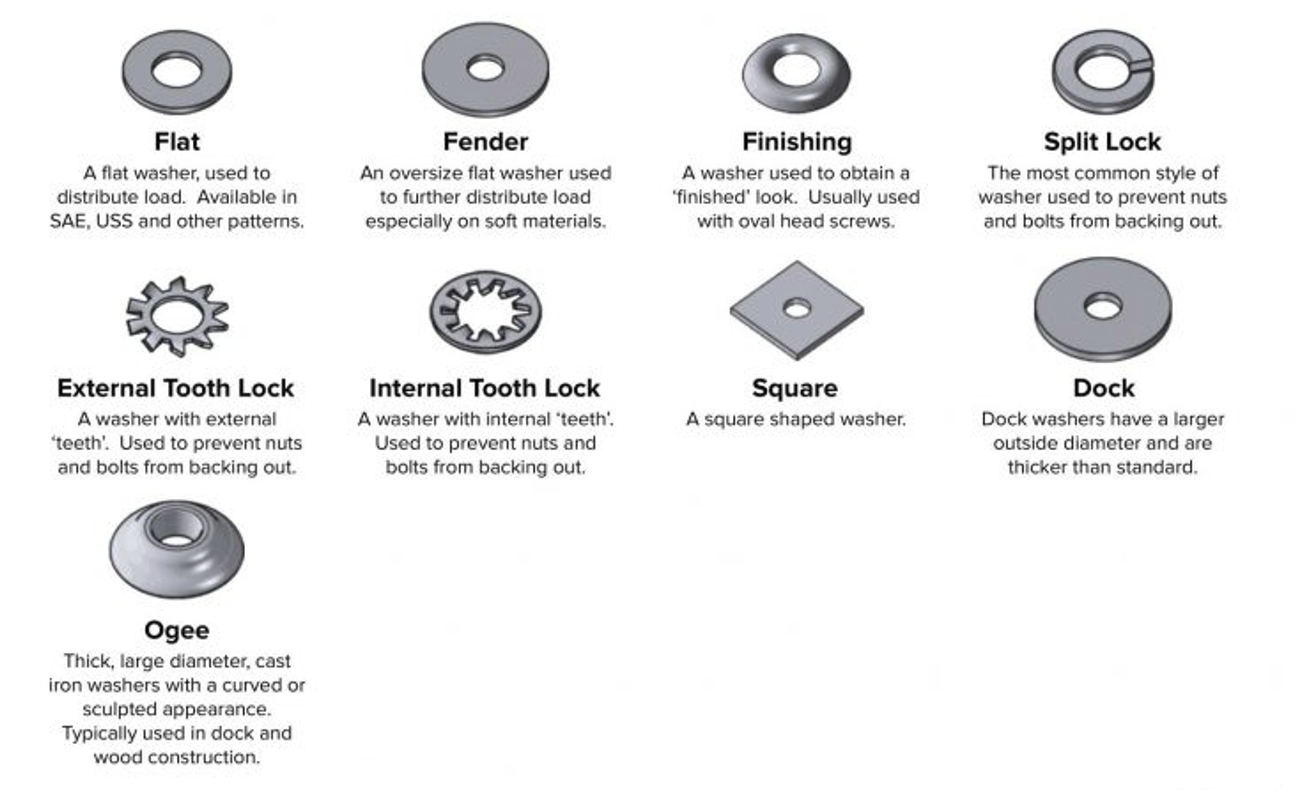

Let’s talk about different types of washers:

Flat Washers

Flat washers cannot be overemphasized in the machining and manufacturing settings. These prevent localized concentration of load at some channels, which may lead to early failure. In this way, flat washers minimize the chances of harm to the outer surface and the prospects of material deformation. In addition to applications, these washers are predominantly used in the automotive, construction, and machinery sectors to add stability.

Spring Washers

Spring Washers

Spring Washers

Image Description: The image shows a close-up of stainless steel spring washers arranged neatly.

Spring washers are also known as split washers. These make sure the fastener does not loosen due to pressure exertion. Moreover, they supply a pre-load that opposes vibration or force wanting to loosen the fastener. Spring washers are likely to have constant movement or vibrations to guard against loosening by fixing them with a snug grip.

Lock Washers

Lock Washers & Nuts

Lock Washers & Nuts

Image Description: The image displays external tooth lock washers and flange nuts used together in automotive and heavy machinery assemblies.

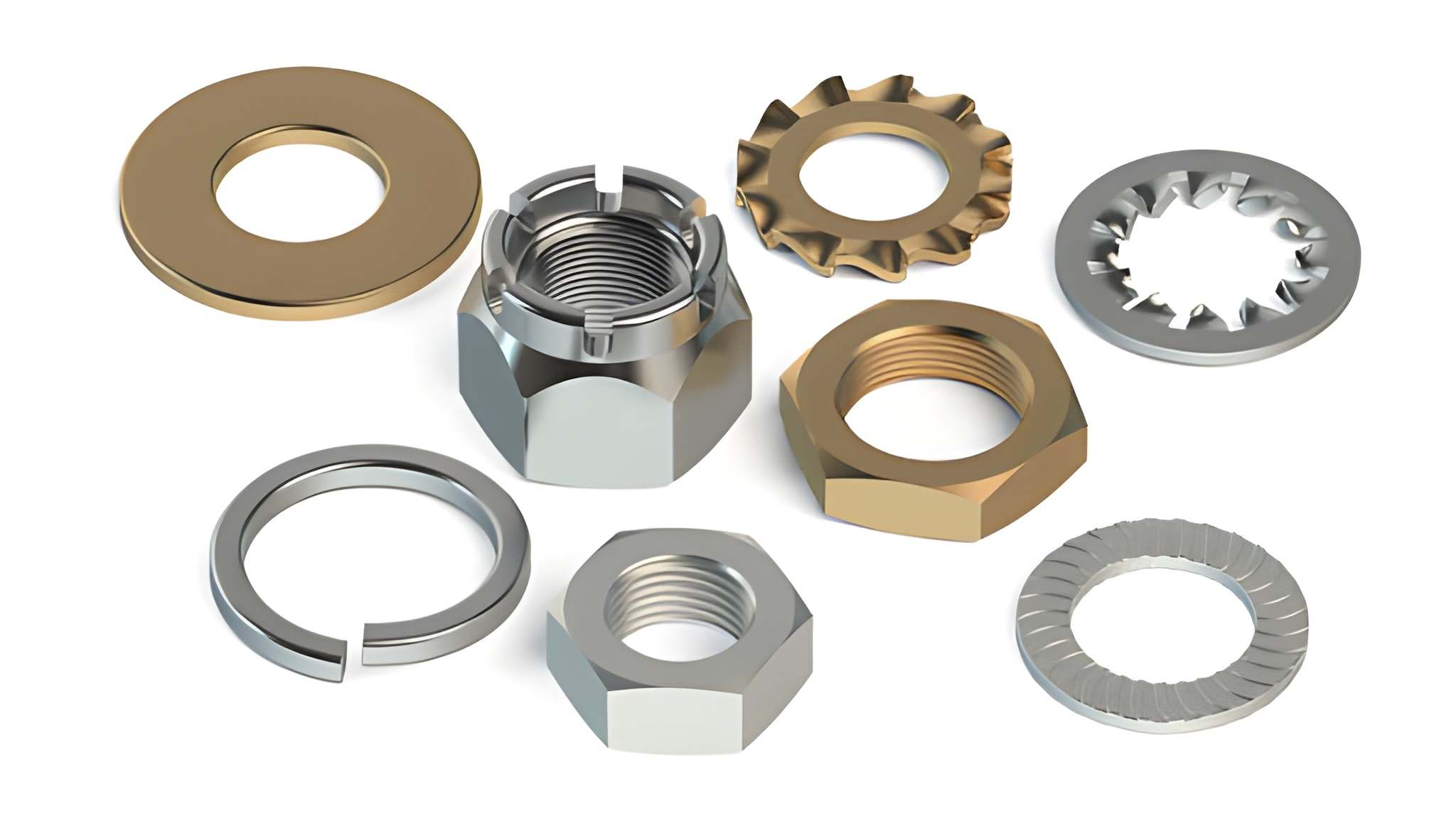

Lock washers are employed to improve resistance to turning. These washers comprise either internal or external teeth that bite into the surface so as not to loosen off. In manufacturing, lock washers are a necessity where high torque and vibration are expected. For instance, their use is common in most engines and large equipment assemblies.

Belleville Washers

Belleville washers are of conical shapes. They are also identified as disc springs. These provide a constant load and force over time. Their conical shape enables them to take a load and deform in response to changes in load. These washers are generally used in cases where you need a consistent force, like in automobile suspensions and industrial presses.

Fender Washers

Fender types of washers are relatively bigger than the flat ones. These washers offer a greater outer diameter, which can provide a larger area to support the load. Hose washers can be used whenever there is a need to distribute pressure evenly on a soft material like sheet metal or plastic, where the fastener may create pressure points. In manufacturing, you can see them in things such as electrical panels or car bodies.

Sealing Washers

Rubber Sealing Fasteners

Rubber Sealing Fasteners

Image Description: The image shows rubber-sealed hex head fasteners used in roofing and outdoor structures to protect against moisture and rust.

These washer accessories prevent leakage by compression between a washer and a surface, ordinarily rubber or silicone. These washers are used widely in processes that actively involve fluids; in plumbing systems, hydraulic machinery, and even in automotive engines.

Shoulder Washers

Shoulder washers are used to clean, position, and part spacing in an assembly line. They go around the fasteners and ensure two parts are correctly aligned, especially in electrical systems or mechanisms. In manufacturing, shoulder washers help avoid short-circuit vibrations or misalignment in delicate equipment.

Countersunk Washers

Countersunk Washers

Countersunk Washers

Image Description: In this image, several countersunk washers are displayed side by side, highlighting their precision-machined bevel and polished surface.

These washers are intended to be used with countersunk holes, which enable fasteners to be flush with the surface. The feature comes in handy in use for cases that require functionality as well as the visibility of the application. Countersunk washers are used in the aerospace or manufacturing industry where the surface is required to be neat and plain.

Rivet Washers

Aluminum Rivets

Aluminum Rivets

Image Description: The image shows a close-up of installed aluminum rivets, forming clean, rounded heads on the surface of an aircraft panel.

Rivet washers are used together with rivets to achieve a tight bearing while time-sharing the load being applied, simultaneously. These washers are helpful where the materials used are too thin for standard hardware. In manufacturing, you will find rivet washers in sheet metal and lightweight components that help the fastener not to mar the surface.

Nylock Washers

Nylock washers are similar in construction to topper washers. These have a nylon ring built into the flat part of the washer that creates friction and resists turning back loose from vibration. Such characteristic makes them suitable for use in machinery and equipment that experience constant mobility.

Specialized Types of Washers

Serrated Washers

Serrated washers hold a cutting edge that clamps into the surfaces so that fasteners do not come loose. They are appropriate for high-vibration uses such as automobiles and mechanical products where security is paramount.

Wave Washers

Wave washers possess waves along their faces, and they typically work under constant pressure while minimizing shock. These washers are suitable for applications that experience a varying load during any movement at all, for example, suspensions.

Tapered Washers

Tapered washers seem like cones. These often distribute pressure on the joint to counteract any slight misalignment. They’re usually applied in precise businesses such as aerospace and automotive production.

Isolation Washers

Isolation washers are typically of insulating material such as rubber, nylon, or similar that do not allow the material to pass electrical conductivity. They are used in electronic circuits and mechanical equipment where parts need insulation for safety or their optimum functioning.

Shoulder Lock Washers

Shoulder lock washers are a combination of shoulder and lock systems. They cannot be loosened while providing correct positioning.

Friction Washers

Friction washers help reduce the motion or rotation of the related component. These washers are commonly applied in gears or rotary joints in the vehicle and aircraft industries.

Double-Ended Washers

Double-ended washers normally keep threaded holes at both ends. These are used for spacing or locking. They are perfect where you need to maintain a fixed distance between two parts, as in machinery and construction.

What Materials are Used to Make a Washer

Metal Washers

Metal Washers

Image Description: In this image, several metal washers of different diameters are displayed.

The metal washers are typically made of stainless steel, carbon steel, and alloy steel, giving better clamping and distribution of loads. They do not rust and can handle high pressure. Therefore, these are extensively used in industries such as the automobile and construction industries, among others. Being rugged, they can offer long-term usage in harsh zones.

Plastic Washers

Plastic Washers

Plastic Washers

Image Description: The image shows a close-up of plastic washers in various colors and sizes, arranged neatly on a white background.

These are alternatives to metal washers manufactured using nylon, polypropylene, and PVC. These are light in weight and do not corrode easily. You get to find them in electrical, plumbing systems, and light machinery. Additionally, they are comparatively affordable.

Copper Washers

Copper washers can effectively conduct heat and electricity. They do not corrode easily, and they can withstand high temperatures as well as electrical usage. So, these are optimum for heat exchangers and electrical parts.

Rubber Washers

Rubber washers use neoprene or nitrile materials. They provide great flexibility to absorb the shock. They form good barriers to prevent leakage in fluids and wear out in vibrating applications. Automotive, hydraulic, and plumbing industries rely on these washers.

Brass Washers

Brass Washer

Brass Washer

Image Description: The image shows a single brass washer placed on a white background.

Brass washers provide high mechanical properties and wear resistance. You can apply these in projects that need to display mechanical properties and look aesthetic at the same time in fashion. For instance, in plumbing, electrical assembly, and decoration. In addition, they are resilient to corrosion, making them ideal for use under extreme conditions.

Aluminum Washers

Aluminum Washers

Aluminum Washers

Image Description: The image shows several aluminum washers arranged neatly on a plain surface.

Aluminum washers are relatively light yet durable and exhibit good strength-to-weight characteristics. These materials are perfect for aeronautical, automotive, or other high-performance engineering uses. These washers also provide the structural strength of the fastener systems, but their overall weight is comparatively low.

Silicone Washers

![]()

Silicon Washers

Image Description: The image shows several silicone washers placed on a neutral background.

Silicon rubber washers can handle stressful conditions of temperature variation and offer flexibility in sealing. They are mainly useful in situations where temperature variations are common. For example, washers are particularly effective in making reliable seals and electrical insulation under difficult conditions.

Zinc-Plated Washers

As the name implies, these washers provide a corrosion-protection layer, since zinc plating, makes it more resistant to rusting. Moreover, these are suitable for applications in high humidity or any form of exposure to moisture, such as outdoors or marine applications that impact the uncoated metals.

Teflon Washers

Teflon washers combine low friction and chemical resistance with high working temperatures. These washers can handle aggressive chemicals or high-temperature systems. So, as you may see them in pharmaceutical industries or chemical processing industries. Teflon washers are ideal for long-term usability in sealing applications and electrical insulation.

Types of Washers: Size Comparison: SAE Vs. USS

When selecting a washer type, machinists often choose between two popular standards: SAE (Society of Automotive Engineers) and USS (United States Standard). SAE washers are generally thinner and more compact, while USS washers are thicker and larger. Below is a unique breakdown of both washer types with their respective sizes.

SAE Flat Washers

| Washer Size | Inside Diameter (inches) | Outside Diameter (inches) | Thickness (inches) |

| #6 | 5/32″ | 3/8″ | 3/64″ |

| #8 | 3/16″ | 7/16″ | 3/64″ |

| #10 | 7/32″ | 1/2″ | 3/64″ |

| 1/4 | 9/32″ | 5/8″ | 1/16″ |

| 5/16 | 11/32″ | 11/16″ | 1/16″ |

| 3/8 | 13/32″ | 13/16″ | 1/16″ |

| 7/16 | 15/32″ | 59/64″ | 1/16″ |

| 1/2 | 17/32″ | 1-1/16″ | 3/32″ |

| 9/16 | 19/32″ | 1-3/16″ | 3/32″ |

| 5/8 | 21/32″ | 1-5/16″ | 3/32″ |

| 3/4 | 13/16″ | 1-1/2″ | 9/64″ |

| 7/8 | 15/16″ | 1-3/4″ | 9/64″ |

| 1″ | 1-1/16″ | 2″ | 9/64″ |

| 1-1/8 | 1-3/16″ | 2-1/4″ | 9/64″ |

| 1-1/4 | 1-5/16″ | 2-1/2″ | 5/32″ |

| 1-1/2 | 1-7/16″ | 3″ | 3/16″ |

USS Flat Washers

| Washer Size | Inside Diameter (inches) | Outside Diameter (inches) | Thickness (inches) |

| 3/16 | 1/4″ | 9/16″ | 3/64″ |

| 1/4 | 5/16″ | 3/4″ | 1/16″ |

| 5/16 | 3/8″ | 7/8″ | 5/64″ |

| 3/8 | 7/16″ | 1″ | 5/64″ |

| 7/16 | 1/2″ | 1-1/4″ | 5/64″ |

| 1/2 | 9/16″ | 1-3/8″ | 7/64″ |

| 9/16 | 5/8″ | 1-1/2″ | 7/64″ |

| 5/8 | 11/16″ | 1-3/4″ | 9/64″ |

| 3/4 | 13/16″ | 2″ | 5/32″ |

| 7/8 | 15/16″ | 2-1/4″ | 11/64″ |

| 1″ | 1-1/16″ | 2-1/2″ | 11/64″ |

| 1-1/8 | 1-1/4″ | 2-3/4″ | 11/64″ |

| 1-1/4 | 1-3/8″ | 3″ | 11/64″ |

| 1-3/8 | 1-1/2″ | 3-1/4″ | 3/16″ |

| 1-1/2 | 1-5/8″ | 3-1/2″ | 3/16″ |

| 1-5/8 | 1-3/4″ | 3-3/4″ | 3/16″ |

| 1-3/4 | 1-7/8″ | 4″ | 3/16″ |

| 1-7/8 | 2″ | 4-1/4″ | 3/16″ |

| 2″ | 2-1/8″ | 4-1/2″ | 3/16″ |

| 2-1/2 | 2-5/8″ | 5″ | 15/64″ |

| 3″ | 3-1/8″ | 5-1/2″ | 9/32″ |

Typical Shapes of Washers

- Spherical Shape

- Square Shape

- Shoulder Shape

- Wave Shape

- C-Shaped

Common Washers Standards You Must Know

SAE Washer Standard

The SAE (Society of Automotive Engineers) standard defines specifications for automotive and mechanical washers. It ensures consistency in sizes, thicknesses, and materials for reliable fastening systems.

USS Washer Standard

The USS (United States Standard) washer standard covers dimensions and thicknesses for industrial flat washers. It provides thicker washers than SAE, supporting applications that require more load-bearing capacity.

ISO Washer Standard

The ISO (International Organization for Standardization) washer standard specifies dimensions, materials, and tolerances for washers worldwide. It ensures compatibility and consistency in global manufacturing.

DIN Washer Standard

The DIN (Deutsches Institut für Normung) standard sets guidelines for washer sizes, materials, and tolerances.

ASME Washer Standard

The ASME (American Society of Mechanical Engineers) standard outlines requirements for washers in mechanical and structural applications. It ensures safe, consistent fastening with specific materials, dimensions, and tolerances.

JIS Washer Standard

The JIS (Japanese Industrial Standards) washer standard defines specifications for washers used in Japan. It ensures high-quality manufacturing and uniformity in washer dimensions and materials across various industries.

Contact Premium Parts To Meet Your Specific Washer Needs

At Premium Parts, we understand that every application requires a properly machined washer for optimal performance. So, our engineers ensure the exact specifications of your project, whether you’re in the automotive, industrial, or mechanical sectors. We offer our customers custom machining options, so you get the best fit for personalized requirements.

Our teams employ high-quality materials and undergo rigorous testing to guarantee the longevity and reliability of washers. Whether you need flat washers, lock washers, or specialized designs, Premium Parts delivers the perfect washer to enhance the performance and longevity of your equipment. We pride ourselves on offering personalized service and fast delivery, and ensuring your project runs smoothly from start to finish.