CNC Machining Cost Explained: Factors, Calculations & Smart Savings for Engineers

It’s a typical task to estimate CNC machining cost. Because one project costs you less, but some other projects could incur unforeseen costs. Complex designs, vague cost breakdowns, and excessive material waste can quickly push...

CNC Precision Machining Parts – A Comprehensive Guide

The modern industry demands quality and precision. From heavy industries such as automobiles and aerospace to the health industry, each relies on precision parts. So, if you are a business owner and need quality parts for your ...

Understanding Prototype Types and How to Build Them Right

Imagine This: You got a great product idea, you researched it well, rendered it in CAD software, but it failed during testing. If you have actually built it and tested it thoroughly, you could have spotted all the cracks. In th...

10 Best CNC Machined Parts Manufacturers in the World (2025)

Ever been stuck choosing a CNC machining partner and thought, “How do I even know which one’s best?” You’re not alone. If you’re an engineer, product developer, startup founder, or a buyer for a big company, then you know that ...

5-Axis CNC Machining: The Complete Guide

You’re working on a life-saving medical device. Everything’s running smoothly…until one small component fails. Why? Because it was made with basic 3-axis machining and couldn’t meet the complex geometry you needed. The part loo...

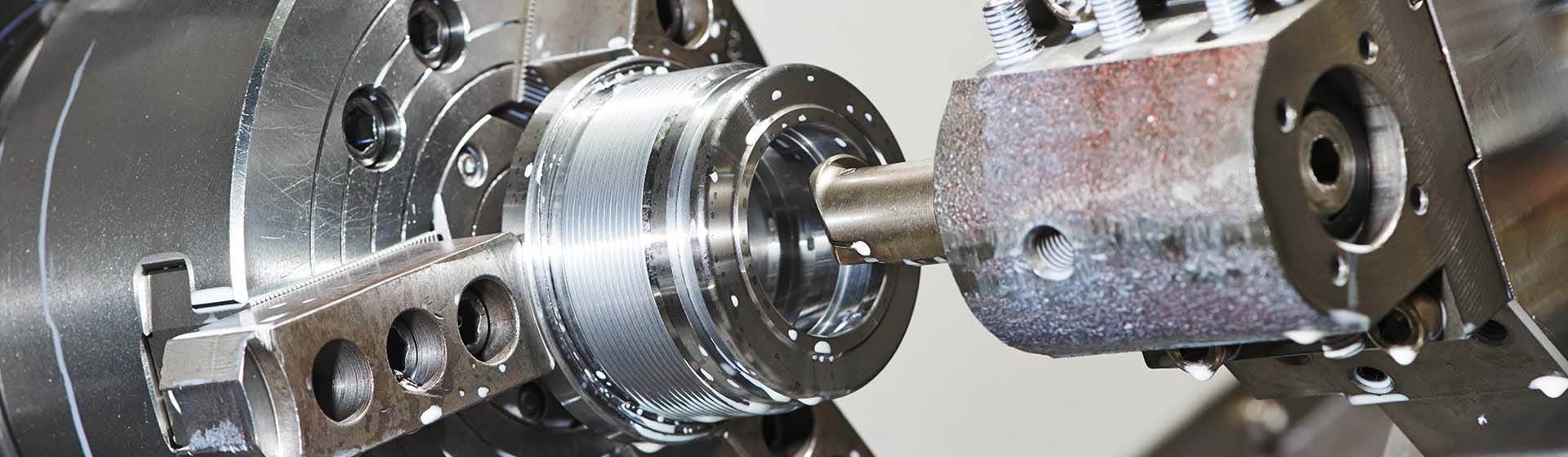

Bespoke Aluminum CNC Turned Parts Manufacturing Guide

What makes aluminum a great match for CNC turning machines? Aluminum is used in everything! It is in aircraft parts, automobiles, and even kitchen appliances. The properties of aluminum make it a popular material to produce qua...

Must-Known Facts About Nickel Plating

Nickel plating, a surface finish treatment, demands close attention. The fact is that it is a metal finishing method that often doesn’t receive the attention it deserves. However, if you’re looking for components that resist co...

On Demand CNC Machining: How it Works & Benefits

Do you need the products urgently but have to wait for weeks? On-demand CNC machining is the solution for you, combining precision with efficiency. Progressive On-Demand CNC manufacturing was developed to meet the changing prod...

Medical Device Machining – Methods, Benefits, and Applications

CNC Machining is the base of many medical devices. Medical tools need accuracy and high quality without minor errors. Besides, these products sometimes need rapid production and high standards. Thus, the medical device machinin...

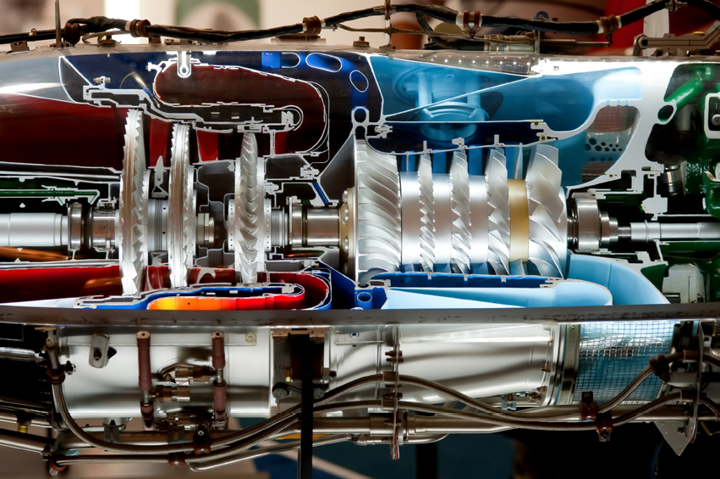

What Is The Role of CNC in Aerospace Machining?

Aerospace leaves no room for guesswork. Precision is critical in this sector. Because safety, performance, and survival at 30,000 feet depend on it. Whether it’s a turbine blade in a jet engine or a structural bracket in ...