Why EV Manufacturers Rely on Automotive CNC Machining

The Automotive Industry is evolving day by day. The requirements of exact-fit components are increasing, and parts need to be fit and perform as intended as a benchmark. However, it’s often challenging to fabricate parts that m...

10 Leading Sheet Metal Fabricators In China, USA, and Europe

Finding reliable sheet metal fabricators is never an easy job. You need parts that fit, function, and last. From enclosures to brackets, precision is always essential. Many projects fail due to poor fabrication choices. This gu...

Injection Molding Surface Finish – A Detailed Overview

You will find injection molding parts everywhere, from automobiles to the aerospace industry. Most manufacturers do not consider the surface finish of injection molding parts. However, design is a major consideration for many i...

Spotface Vs Counterbore Hole: A Machinist’s Guide

If you belong to the precision manufacturing industry, you would agree that even the smallest things can make the biggest differences. For example, how well all the screws fit a part. This is where a hole and its features come ...

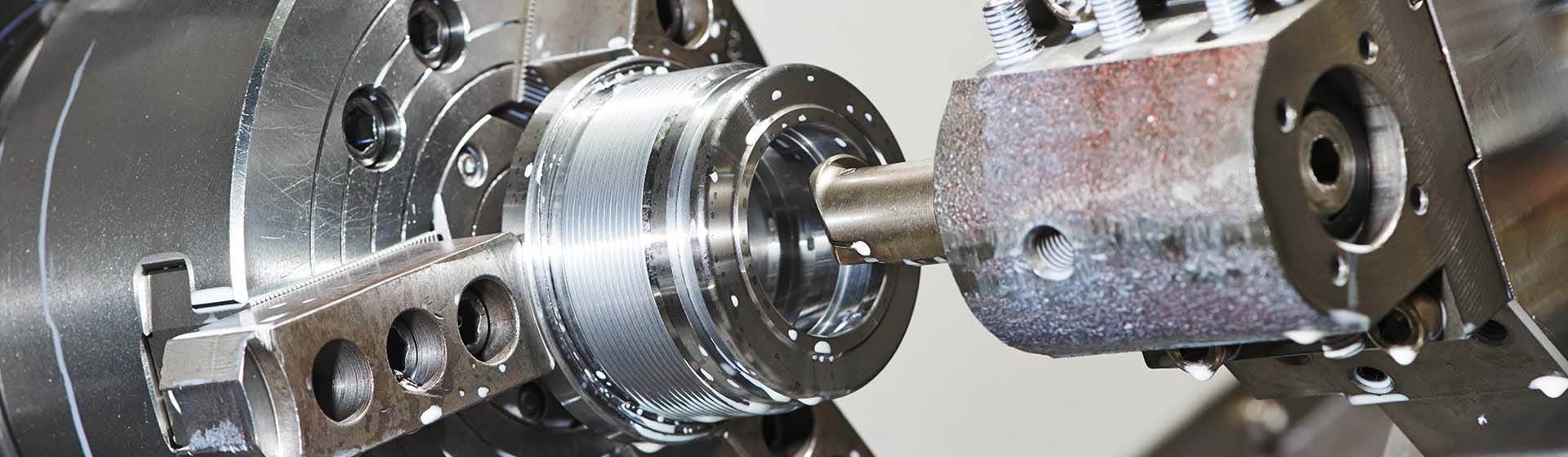

A Complete Guide to Micro CNC Machining

Medical implants and the everyday use of miniature parts inside our gadgets are dictating that the world is shrinking and becoming more precise. Because new advances are making products smaller but more advanced. Businesses now...

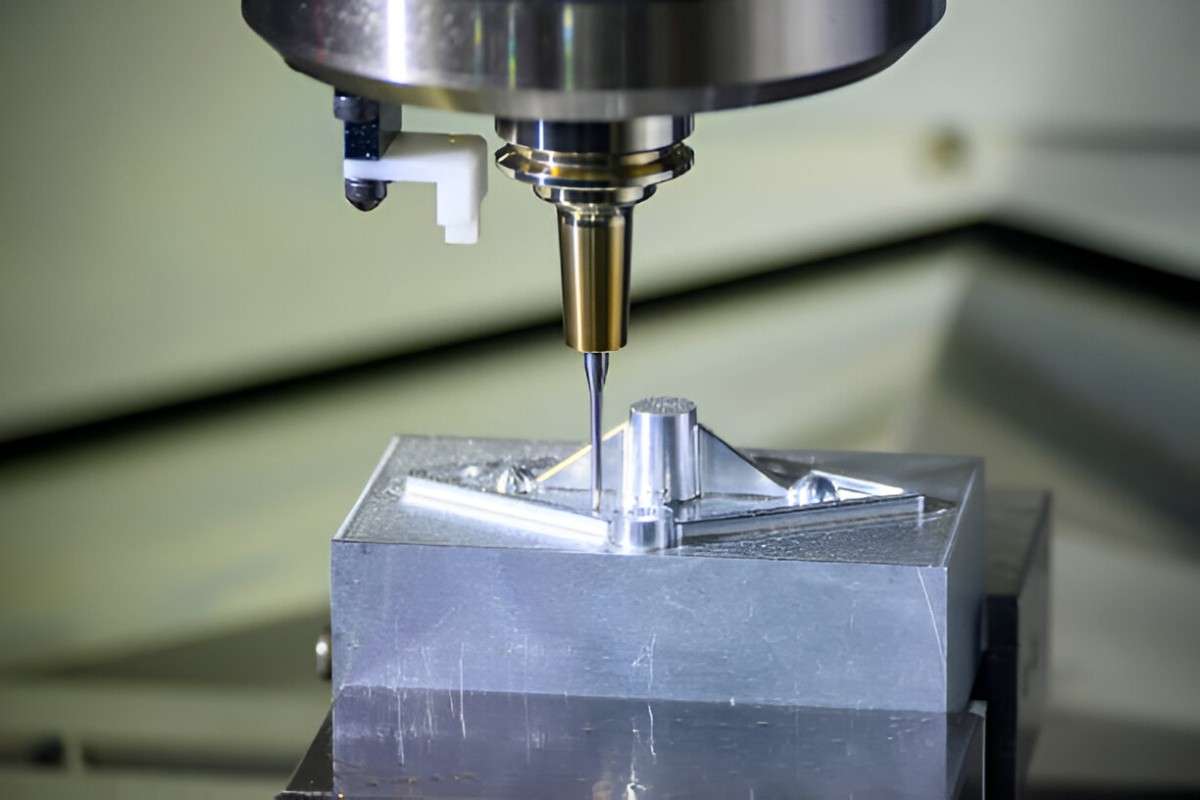

Deep Cavity Machining: A Complete Walkthrough

Deep cavity machining is the backbone of CNC machining. It does not depend on which kind of material you are working with. Areas like deep cavities and hidden crevices are very problematic to reach with CNC machines; they bring...

What Is Tool Offset in CNC Machining: A Complete Guide

CNC Machining accuracy is not based only on the machine. It also depends on the operator’s expertise. The way you manage every detail, especially the ones most machinists overlook, makes a big difference. Tool offset is ...

Bar Stock vs Plate Stock: Making The Right Decision

In modern manufacturing, choosing the right material for your project is essential in building efficient, yet long-lasting products. Now, this is where bar stock and plate stock come in. They are among the most used raw materia...

Rubber Overmolding: Process, Benefits & Uses

Rubber overmolding is a two-stage process. It is used to increase product grip, absorb impact, and add comfort, all in one step. Additionally, it reduces the need for additional assembly. The process is used in aerospace, gun, ...

Kovar Alloy Machining: A Complete Walkthrough

Kovar alloy machining is an essential technique in precision manufacturing. It requires two things: a lot of patience and a skilled technician who knows the right way to operate the machinery and tools. Kovar itself is a metal...