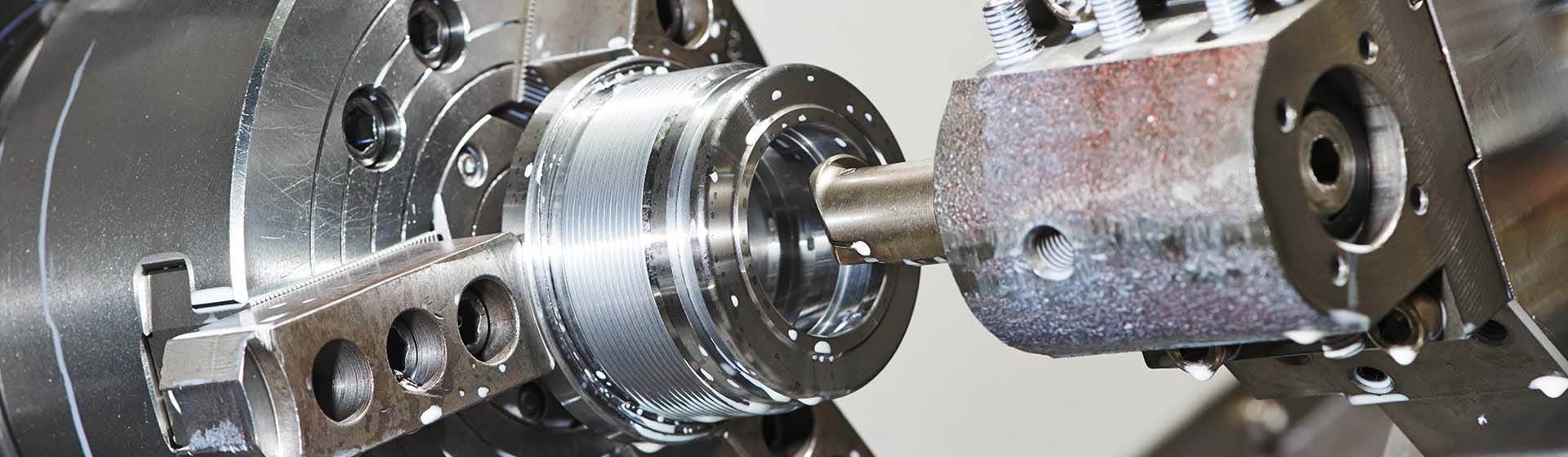

Bespoke Aluminum CNC Turned Parts Manufacturing Guide

What makes aluminum a great match for CNC turning machines? Aluminum is used in everything! It is in aircraft parts, automobiles, and even kitchen appliances. The properties of aluminum make it a popular material to produce qua...

Must-Known Facts About Nickel Plating

Nickel plating, a surface finish treatment, demands close attention. The fact is that it is a metal finishing method that often doesn’t receive the attention it deserves. However, if you’re looking for components that resist co...

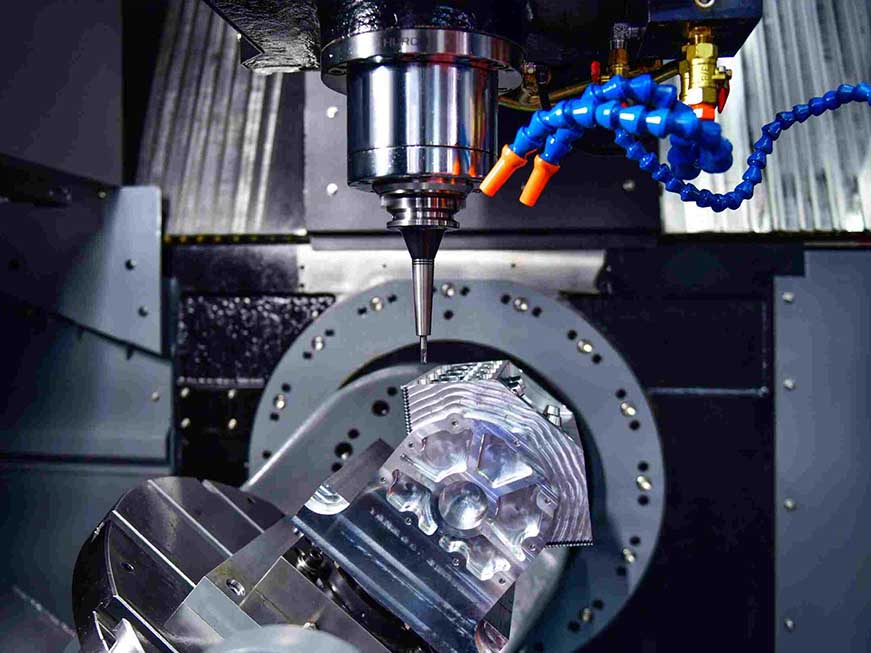

On Demand CNC Machining: How it Works & Benefits

Do you need the products urgently but have to wait for weeks? On-demand CNC machining is the solution for you, combining precision with efficiency. Progressive On-Demand CNC manufacturing was developed to meet the changing prod...

Medical Device Machining – Methods, Benefits, and Applications

CNC Machining is the base of many medical devices. Medical tools need accuracy and high quality without minor errors. Besides, these products sometimes need rapid production and high standards. Thus, the medical device machinin...

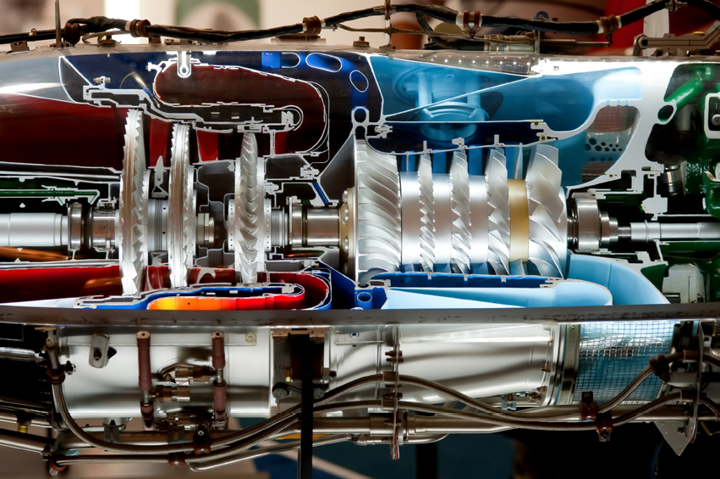

What Is The Role of CNC in Aerospace Machining?

Aerospace leaves no room for guesswork. Precision is critical in this sector. Because safety, performance, and survival at 30,000 feet depend on it. Whether it’s a turbine blade in a jet engine or a structural bracket in ...

What is Zinc Plating? Process, Types, & Specifications

Zinc plating is a special method to protect metals from corrosion and enhance their durability. It’s a reliable procedure to protect the metals from environmental elements such as water and air. That’s why manufactu...

CNC Machining Defects & Preventive Takeups_ A Practical Guide

Many industries rely on CNC machining due to its accurate, repeatable, and productive outcomes. However, even in advanced workplaces, errors can occur. Irregularities, errors in sizing, or internal breakdowns due to stress can ...

How Much Does CNC Machining Cost Per Hour

Let’s be honest, if you’re developing a product, pricing matters. And not just in the “let’s stick to the budget” kind of way. I mean it really matters. Because if you’re choosing the wrong manufacturing partner—or payin...

10 Major Industries That Use CNC Machines

Robotic CNC Machining Image Description: The image shows a robotic arm handling metal parts during CNC machining. It highlights automation in the manufacturing process. Unless you work with machines or make things for a living,...

What is CNC Precision Engineering and How Does It Work

Many industries rely on CNC precision engineering to offer high-end precision parts. The parts provide good tolerances and glossy, smooth finishes. Besides, CNC parts are reliable in terms of applications that meet modern needs...