Low Volume Machined Parts Displayed

Low Volume Machined Parts Displayed

Image Description: Low volume machined parts neatly arranged inside a wooden display box.

In our last post, we covered the tremendous benefits of low-volume manufacturing. Today, we will look at the steps and techniques that can drive a successful low-volume production run.

Additive manufacturing and digital technologies have significantly sped up low-volume manufacturing. Users can print CAD models from their desktops to 3D printers by simply pressing a push button switch. Meanwhile, CNC machines enhance productivity thanks to the installation of powerful software. With consumers demanding instant gratification now more than ever, businesses, both large and small, will inevitably have to run low-volume production. The key to effective low-volume manufacturing will comprise a good team in tune with the latest technologies, design expertise, flexibility, and a solid supply chain. Let’s take a look at each of these factors in more light.

• Planning Product Design

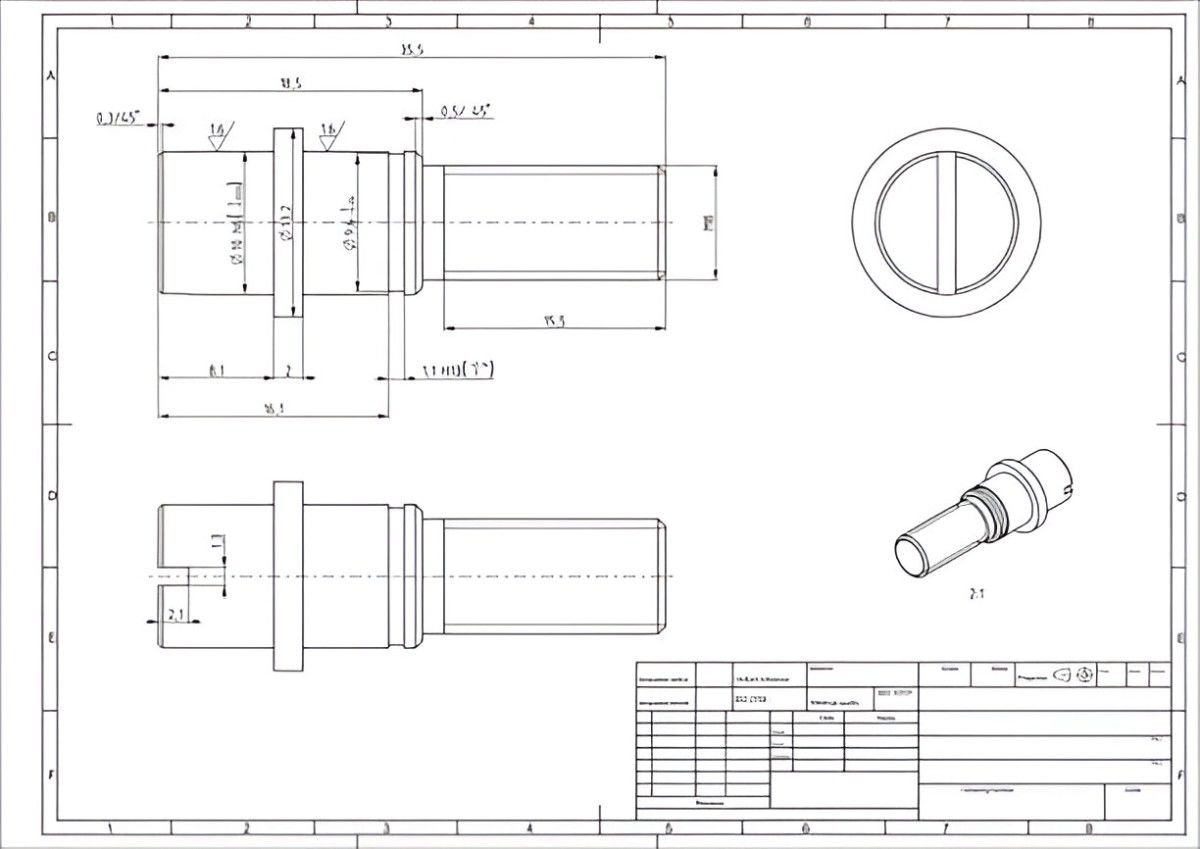

Metal Part 3D/Virtual Footprint

Metal Part 3D/Virtual Footprint

Image Description: A 3D CAD design showing the virtual model of a metal part.

The first step in any production run is the planning stage. It is the same for low-volume manufacturing. As production is usually a continuous process from start to finish, it is always important to have all the features of the product figured out.

• Finalizing Design Specifications

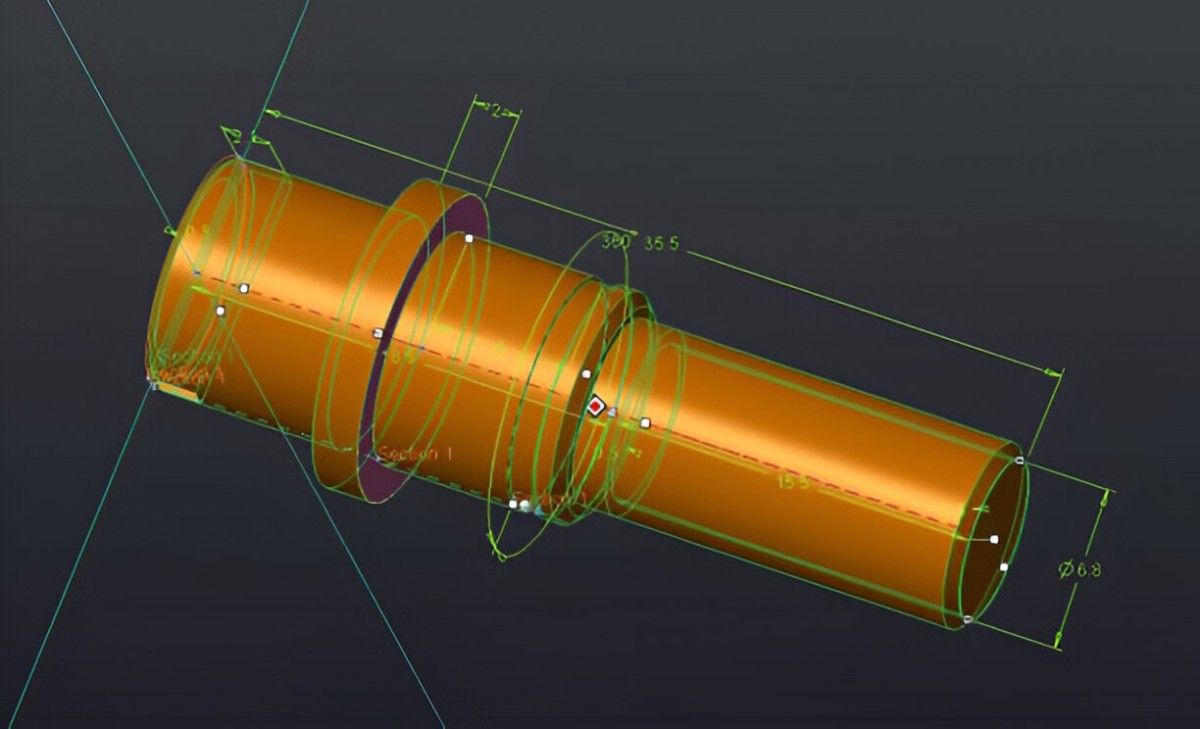

3D Design Conversion to Finished Product

3D Design Conversion to Finished Product

Image Description: A realistic 3D render showing the metal part in its final form.

Design specifications cover all the relevant details regarding the design and production of your part. After planning the product design, decide on specifics such as the desired material for production, the colour of the finish, the dimensions, size, weight, and strength of the final part.

• Connecting to Resources and Expertise

After finalising all the internal decisions, it is time to look outward. In this stage, your business is not simply looking for a supplier that can run the production but for a supplier that can run the job cost-effectively using efficient methods that maintain quality.

Your chosen supplier should have a decent amount of experience in the field, know what technology to use, understand the functional and mechanical properties of the selected materials, and, most importantly, be able to deliver a high-quality prototype that works just as intended.

• Employing Appropriate Technology

Low Volume CNC Machined Cylindrical Parts

Low Volume CNC Machined Cylindrical Parts

Image Description: Stacked low volume CNC machined cylindrical parts displayed together.

Using the right technology will not only help you produce a perfect product, but it will also save you time, effort, and money. For low-volume manufacturing, each technique has its pros and cons. 3D printing will serve for quick prototyping and is excellent for design evaluation before producing higher volumes. CNC machining can deliver great quality parts at very appreciable rates as well.

• Cementing the Supply Chain

No matter how well-designed your prototype or production part is, you will face challenges in your production run if your supply chain is weak. Try to ensure that the material you have selected is readily available in mass quantities, easy, and inexpensive to ship.

Also, consider the factory location where your low-volume production is running. If the area is not accessible, you may have problems getting raw materials across.

Challenges in the supply chain and logistics may ultimately cripple production.

• Post-production Services

CNC Aluminium Anodized Fittings part

CNC Aluminium Anodized Fittings part

Image Description: Red and blue CNC-machined aluminum fittings with an anodized finish.

After running the production of your part, it is also important to carry out all relevant post-production or finishing services. These could include coating, painting, metalising, anodizing, and other finishing operations.

Post-production services may improve appearance, aesthetics, functionality, strength, and abrasion resistance.

Premium Parts, Low-volume manufacturing Services in China

Premium Parts offers high-quality CNC machining services and other low-volume manufacturing processes for producing precision parts. Our expertise ranges across a number of services, and we can generate exceptional quality products with a quick turnaround. We can work with an extensive range of materials and produce low and mass-volume manufacturing. Our engineers are full of experience in delivering best-in-class manufacturing quality and standards.