CNC Machining

CNC Machining

Image Description: A CNC machine is cutting a metal part with high precision.

CNC Machining refers to Computer Numerical Control machining. It is a method of using computer-controlled devices to perform a series of production tasks. CNC Machines have been around since the late 70s and have gradually replaced conventional machining in most countries. It makes use of Computer-Aided Machining (CAM) and Computer-Aided Design (CAD) functions.

CNC machines hold numerous benefits over traditional machines. Because of the computerized approach, these devices are programmable and controlled to deliver more accuracy, higher repeatability, and a quick turnaround. CNC machines also allow for the fabrication of complex-geometry parts because of their operation across 3 and 5-axis.

Types of CNC machines

There are different types CNC machines. Below is a brief on the most common types of CNC machines that are used in everyday manufacturing:

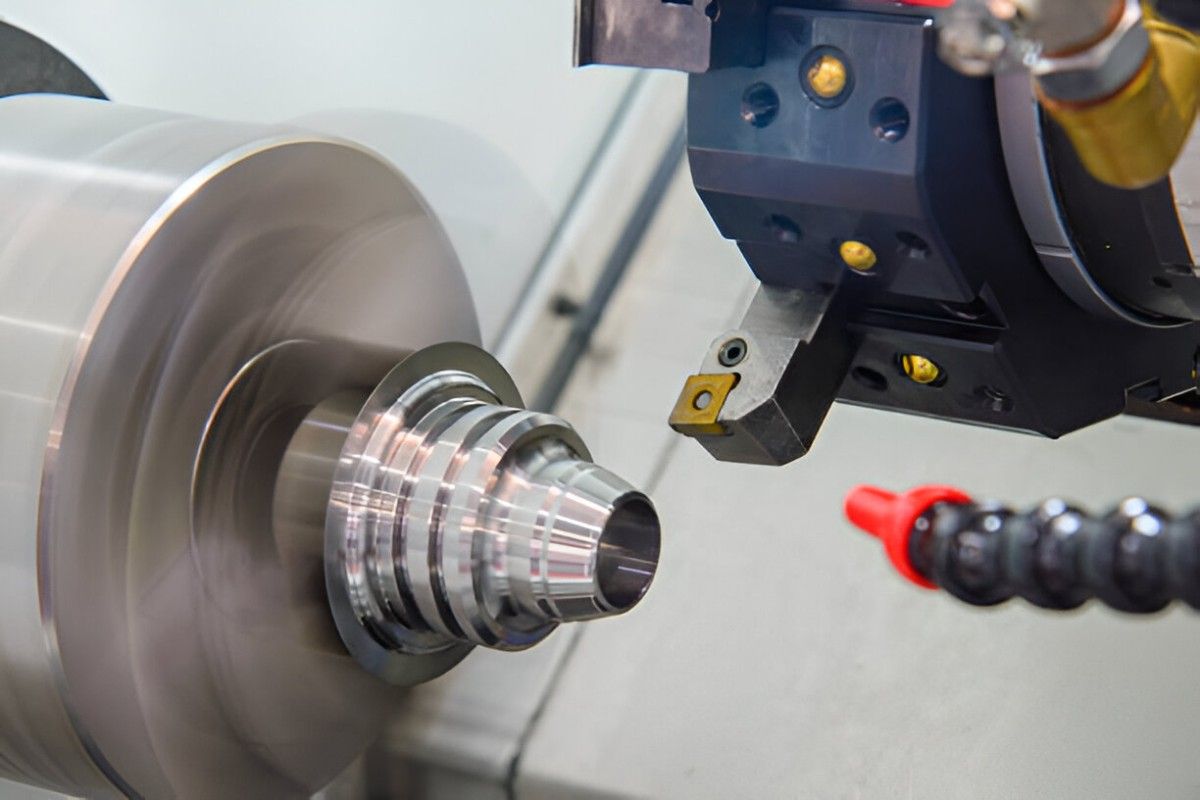

CNC Lathing

CNC Lathe Machine

CNC Lathe Machine

Image Description: A CNC lathe machine is rotating a workpiece while cutting it into shape.

CNC lathing is used in cutting parts of a workpiece in a circular direction with high speed and accuracy. Most lathe machines have two axes, but may be used to produce parts with complex geometries that may not be producible on manual lathes.

CNC Milling

CNC Milling

CNC Milling

Image Description: A CNC milling machine is cutting a precise shape part using a rotating tool.

CNC milling is a CNC-machining process that uses computerized controls to direct a rotating multi-point cutting tool to produce a final product by systematically removing material from the initial workpiece material. In simpler terms, a CNC mill progressively produces a final piece of work by eliminating parts of material till the desired form is attained. CNC milling is typically best employed as a secondary or finishing process for a workpiece that has already been machined. It is perfect for adding certain defining features to a part, such as slots, threads, holes, or bends.

CNC Cutting

CNC Cutting

CNC Cutting

Image Description: A CNC laser cutting machine is cutting a sheet of material with a focused laser beam.

CNC cutting may be oxy-fuel cutting, laser, or water-jet cutting. Generally, the cutting process involves the cutting and slicing of metal materials using plasma, oxy-fuel, or water jets. The technique used usually depends on the nature of the materials to be cut. Plasma cutters slice through materials with the speed and heat generated through compressed air, gas, and electrical arcs. Water jet cutters utilize high-pressure water streams mixed with strong abrasive substances that increase the ease of cutting.

What are the benefits of CNC Machining

Benefits of CNC Machining

Benefits of CNC Machining

Image Description: The infographic presents 10 benefits of CNC machining.

There are far too many benefits of CNC machining to cover in this post. A summary of the advantages of using CNC-machining for your business is outlined below:

1. Increased Productivity

CNC machining has generally improved output and efficiency of resources in the manufacturing space, as work is delivered with quicker turnaround without compromising on the standard of the outputs

2. Time and Money

CNC machining requires far less human involvement than traditional machining. This can help to reduce labor costs. The use of these computerized methods and automation also guarantees that many customer orders are delivered in less time because of the higher speed and precision when compared to human input

3. Reduces Material Waste

CNC machines are programmed with CAM and CAD inputs. These ensure a high level of accuracy and precision. Because of this automation, human errors are eliminated, and therefore material wastes are minimized. Generally, you can get more output from the same level of input when working with CNC machines over traditional, manual machining.

4. Safety and Ease of Use

CNC machines tend closer to the HSE rules on every production floor. Since the machines are to a larger extent computerized, there is minimal need for an operator to get close to the cutting tools. There is, therefore, a lower risk of occupational hazards than when workers are interfaced directly with the tools.

5. Eliminates human errors

Except when intentionally overridden, computer programs will continue to deliver excellent output that works as intended. This is because once preset, CNC machines will never deviate. Errors such as shortages, misfits, detailing, degree of straightness, and more will all be eliminated as human input is significantly reduced, and the machine will only work as per the design data.

6. Futuristic

Using CNC machines in your business almost guarantees that your business is future-proof. Although CNC machines have been around since the 1970s, many future technologies for manufacturing will continue to be built around this technology. 3D printing technology is just an example of techniques that may be incorporated with CNC machines. CNC machines are also program-based, guaranteeing that improvements to come will most likely be compatible with the hardware you have, rather than a software installation or update.

Premium Parts CNC Machining Services in China

We offer high-quality CNC machining services that are optimized for the production of many precision parts at Premium Parts. Our expertise ranges across several services, and we can generate exceptional quality products with a quick turnaround. We can work with an extensive range of materials and produce both mass-manufactured volumes and low-volume manufacturing. From CNC machining to 3D printing and rapid injection molding, our engineers are highly experienced to deliver best-in-class manufacturing quality and standards.