High-density polyethylene (HDPE) is almost everywhere you look—milk jugs, detergent bottles, water pipes, and cutting boards. The material is credited with its durability, lightweight, and chemical resistance, making it one of ...

How does mold wall thickness affect injection molding? Why is it essential for determining part accuracy and manufacturing efficiency? The answer lies in wall thickness. It helps improve cooling and material flow and mitigates ...

Are you looking for ways to enhance your product’s durability and improve its appearance? Reducing production costs while maintaining quality is undoubtedly a significant challenge. The two major issues product manufacturers fa...

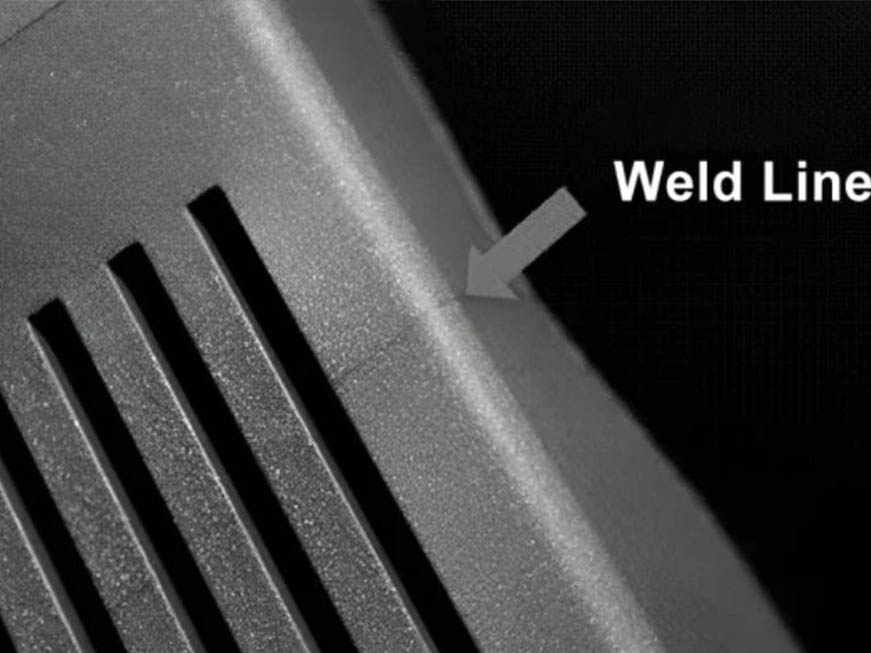

Injection Molding Weld Line Image Description: A close-up image of a plastic injection molded part showing a visible weld line, with the area clearly highlighted by overlaid text. Any defect in the finished part will leave you...

Choosing the right manufacturing process can either make or mar your project. Being an engineer, working on a new product for your customer. You may need to test various prototypes before advancing to or commencing mass product...

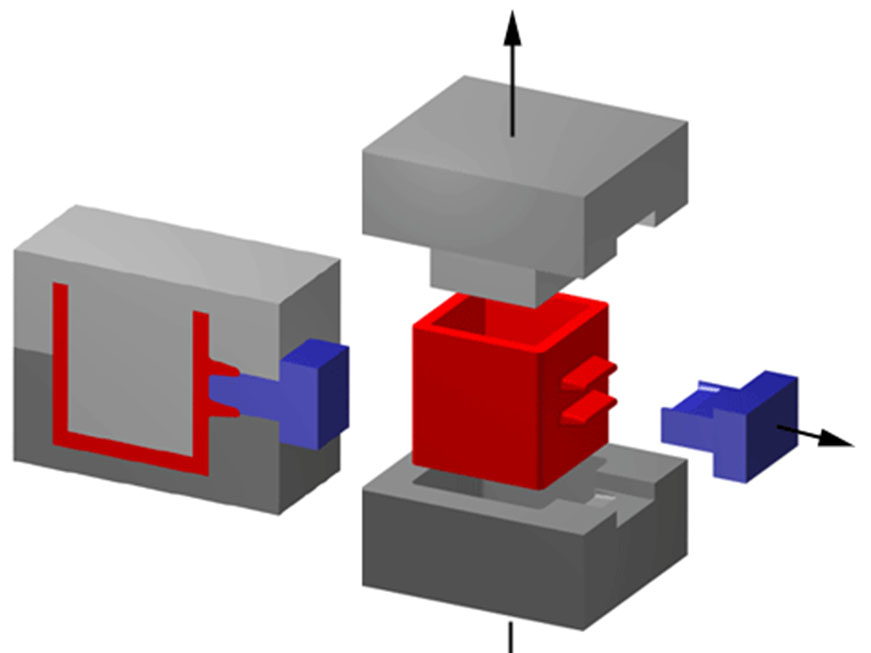

If you’re using injection molding side action for design optimization, CNC advancements have made the process more precise. Through side actions, designers can create intricate designs that maintain functional improvement...

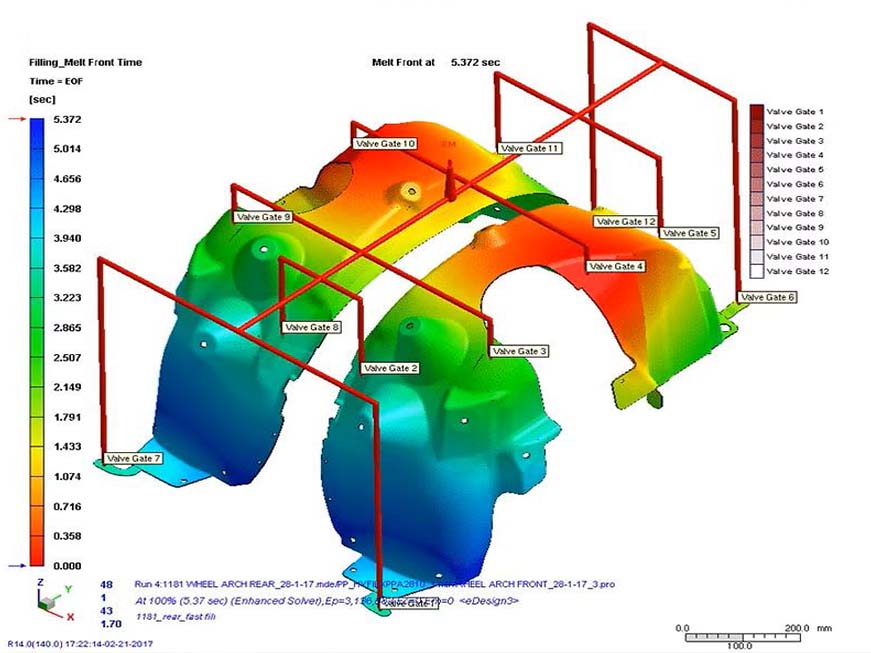

The Mold Flow Analysis provides significant support for manufacturing products by simulating material flow in mold applications. You, as a machinist or engineer, can use a mold analysis approach to make your desired product. Th...

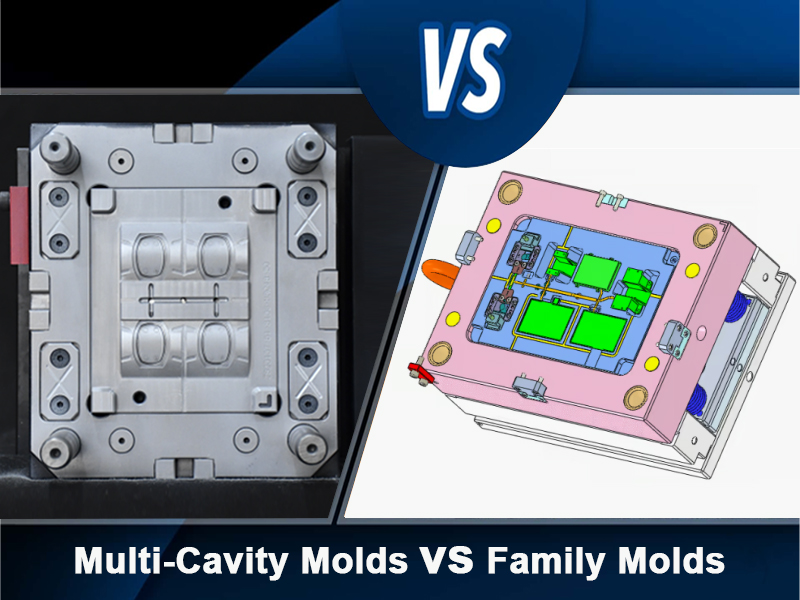

Multicavity Mold Vs Family Mold Image Description: A side-by-side illustration comparing a multicavity mold and a family mold. Injection Molding helps make precise parts because it gives consistent and exact results. The kind ...

Why You Should Use Custom Resins for Your Injection Moulding Process? While CNC machining and 3D printing continue to advance at relatively rapid rates, the same cannot be said for injection moulding. Injection moulding is one ...

Plastic PVC Valves Image Description: PVC Plastic valves are displayed on a table. The plastic parts manufacturing industry has experienced significant growth over the past few decades. Through technologies such as 3D printing,...

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.