When exploring the machining space, you’ve likely researched the costs involved. You may have also considered the expenses of Prototypes and CNC turning. You might have even asked, Why is CNC so expensive? CNC machining offers high precision and flexibility. However, the seemingly high price often makes customers question its worth. Yes is the short answer—and this is why.

This blog will explore the price of CNC milling machines. It will cover advanced 3-axis technology, expensive models, and factors influencing their cost. We will also explore ways to save costs in the manufacturing process. This includes identifying the least expensive plastic CNC processes. Additionally, we will discuss how Premium Parts offers affordable and high-quality CNC machining.

What is CNC Machining?

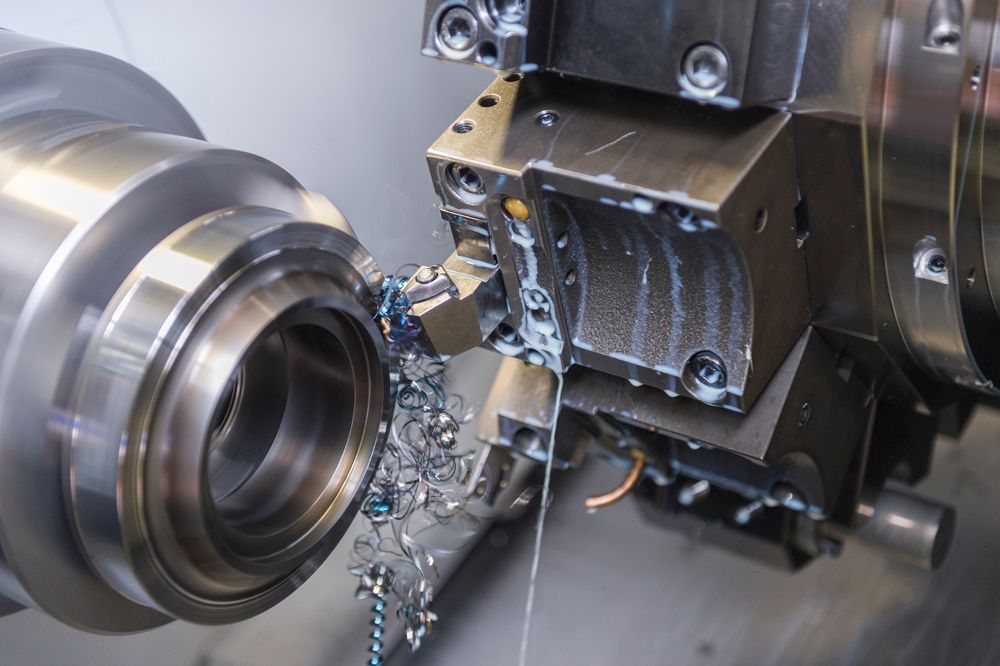

First, it is essential to understand what CNC machining is. Knowing how it works helps in understanding the cost factors associated. It is a subtractive manufacturing technique, or says material removal technique, typically involving precise cutting, shaping, and drilling. It can precisely process materials like metals, plastics, and composites using computer-guided systems.

Instead of manual machining like in the days since the Stone Age, CNC produces an overall automatic procedure, resulting in much better (and quicker) parts.

How does CNC Machining Work?

A CNC machine operates using instructions programmed in G-code, and many other formats. These instructions control the machine’s movement across multiple axes. Take, a 3 axis CNC milling machine, which moves in X, Y, and Z axes to carve intricate designs. High-end models, like expensive CNC 5-axis milling machines, offer rotational capabilities. They provide greater versatility in machining. These machines handle complex geometries required for aerospace and automotive parts.

The technology behind CNC machines enables them to achieve micron-level accuracy. This precision allows them to produce components that manual machining cannot achieve. These advanced capabilities ensure high-quality results. The intricacy of these cuts is what makes CNC desirable and expensive.

Factors That Impact CNC Machining Costs

If you ask, Why is CNC so expensive?, you have to understand that certain critical factors are responsible for these costs:

The Cost of the CNC Machines Themselves

CNC machine prices vary based on their capabilities. Some machines cost very little. Others can cost millions depending on their features.

- Some of the small CNC milling machines intended for simple applications have an entry price much lower, of $5,000.

- The prices of 3-axis CNC milling machines can be around $20,000 to $100,000.

- At the high end, the most expensive CNC machines can cost up to $500k. These include exact 5-axis systems. Engineers equip them with advanced automation, cooling systems, and sensors. They design these machines for high-accuracy applications. Such applications include aerospace and medical machines.

High upfront costs are staggering, but high-performing upscale machines pay off in the long run. This has enabled manufacturers like Premium Parts to make tight-tolerance parts with very high consistency.

High-Quality Material Requirements

Another factor that affects the CNC machining price is the cost of materials. Many industries require aerospace-grade aluminum and stainless steel for their processes. They also use heat-resistant plastics to meet specific needs. These materials ensure durability and performance in demanding environments. These materials are more durable and, naturally more expensive. They also cause increased tool wear in the machine. This results in higher maintenance requirements.

For example:

- ABS or acrylic are the cheapest plastic CNC projects and are both pretty inexpensive and enjoyable to machine.

- Conversely, both titanium and Inconel for use in more specialized CNC prototypes or parts can be pricey.

Labor and Expertise

Skilled professionals program CNC machines to ensure smooth operation. They choose the right tools for each task. They also supervise the project to ensure successful completion. Although CNC machining is fully automated, human expertise is essential. The specialist ensures the production process runs smoothly. They minimize wastage during production. They also work to reduce errors as much as possible. Technical expertise ensures the success of a project. However, providing this expertise comes at a premium expense.

Our well-seasoned engineers and machinists handle every part of the journey. They manage everything from CNC prototype service consultation to final inspection. This process guarantees that we produce high-quality parts for you. We achieve this without adding extra costs.

Programming Complexity

The more complex your project, the longer it takes to generate G-code. G-code provides computer instructions for the CNC machine. Complex designs with multi-axis machining require more effort. Tight tolerances and custom finishes also increase programming time. This extra work ultimately raises the overall cost.

For example, programmers must set a highly detailed CNC turning machine precisely. This ensures the production of perfect parts. Custom prototypes or low-volume production runs require even more precision. These setups usually demand much more labour-intensive work.

Maintenance and Tooling Costs

You must regularly maintain high-precision CNC machines to ensure continuous optimal performance. Cutting tools and bits wear down constantly, especially when machining rigid materials. You need to replace them frequently to maintain efficiency and quality.

Finally, manufacturers transfer these maintenance and operational expenses to the overall CNC milling machine price. As a result, clients bear the cost indirectly.

Production Volume and Lead Times

The production volume is another factor affecting the cost of output. Low-volume batches and one-off custom CNC prototypes cost more per part. Fixed setup expenses make these projects more expensive. This is why the per-part price is higher.

However, producing more units spreads the cost per part, lowering the price. Furthermore, tight lead times can also cause rush fees, adding to costs.

Industry Standards and Quality Control

Design controls are crucial in the medical, automotive, and aerospace industries. These industries require stricter quality controls for their products. Ensuring high standards is essential for enterprise-level applications.

High-end CNC services use advanced inspection technologies. They often employ coordinate measuring machines (CMMs). These machines ensure each part meets tight tolerance levels. These extra measures thus create additional costs.

Cost Breakdown for CNC Machining

Here is a table of the common cost factors in creating CNC machined costs:

| Factor | Description | Impact on Cost |

| Material Type | The material chosen (aluminum, steel, titanium) will affect cost depending on availability and machinability. | High

|

| Complexity of Design | It is more time- and precision-consuming and hence involves increases in setup and machining costs. | High |

| Tolerances and Accuracy | Advanced tools and advanced expertise are needed to achieve tighter tolerances and which increase costs. | High |

| Batch Size | Because setup costs flattened over fewer parts, smaller quantities lead to higher per-part prices. | Medium to High |

| Surface Finishes | Anodizing or polishing may be special finishes and add extra processing steps. | Medium |

| Lead Time | However, there can be added fees for rush orders, which will have them expedited for production. | Medium to High |

| Industry Standards | But industries such as aerospace or medical have harsher quality requirements and thus a higher inspection cost. | High |

From this table we can understand the main cost estimations in CNC machining projects. Modulating these factors equilibrates budget, quality, and lead time constraints.

Is CNC Machining Worth the Investment?

Yes, absolutely. CNC machining delivers incomparable precision, guaranteeing that it brings your designs to life with micrometer accuracy. Moreover, its automation reduces human error, making it harder for other methods of manufacturing to offer the same kind of consistency.

CNC is invaluable for industries such as automotive or aerospace, with high-performance or safety requirements.

Why Premium Parts is the Best Choice for CNC Machining?

However, we at Premium Parts know that CNC machining can appear to be pricey. It is for that reason that we have designed our services to consider customer value.

- Advanced Technology: We use the latest technologies to produce flawless components. These include CNC milling machines and CNC turning machine parts. Our advanced equipment ensures high-quality results.

- Cost Transparency: We partner with you to optimize project costs. This includes material selection and proper machine choice. We also discuss the least expensive plastic CNC Our goal is to ensure cost-effective solutions.

- Custom Consultation: We provide CNC prototype services for mass production or single prototypes. Our services cater to customized business cases. We tailor each solution to fit your purpose.

You won’t just pay for CNC machining when working with us. Our service offers much more than that. We provide additional value beyond basic machining.

Practical Tips To Control The CNC Machining Costs

Although CNC machining seems expensive, you can manage and reduce CNC machining costs in several ways.

- Simplifying designs: Simplifying designs reduce the number of programming passes. It also minimizes the machine’s cutting time, lowering overall costs.

- Choose the Right Material: Pick materials that have the best cost and functionality ratio (ABS for visual prototypes instead of polycarbonate).

- Batch Sizes: Larger production runs automatically lower costs per unit. Frequent larger runs also reduce expenses. This happens due to economies of scale.

- Operational Expertise: At Premium Parts, we leverage expertise in every aspect of our business. We support you with end-to-end decisions. Wherever possible, we cut costs for you.

Final Thoughts

The price of CNC machining reflects its true worth. It offers precision, adaptability, and reliability beyond most manufacturing methods. CNC machining ensures accuracy in both prototypes and high-volume runs. The efficiency and quality provided justify the investment.

Get started today, or contact us to learn the cost of CNC machining. You may contact Premium Parts right away! Our experts are ready to guide you through the process. They will provide cost-effective, high-quality manufacturing solutions for your business needs.

Crank the CNC to the entire gain with Premium Parts today!

FAQs

Q1. What is CNC machining?

CNC machining is a manufacturing process where computerized controls remove and manipulate raw materials. It also transforms it into finished parts and products.

Q2. How accurate is CNC machining?

One of CNC machining’s best traits is its precision. It delivers tolerances as low as ±0.001 inches or better. This makes it ideal for manufacturing processes. It is handy where high accuracy is essential.

Q3. Is CNC machining expensive?

The cost of CNC machining varies due to many factors. These include material type, design complexity, and production volume. Machine operating time also affects the price. Despite this, CNC machining offers cost efficiency. It minimizes waste, making it cost-effective in the long run.

Q4. What materials can CNC machines use?

CNC machines can machine a variety of materials. It includes plastic, metal (such as titanium, steel, and aluminum), composite materials, and wood.

Q5. How long does it take to get CNC-machined parts?

The lead times depend on the complexity of the design and production requirements. Simple parts may take a few days, whereas complicated ones will take longer.

Q6. Can you employ CNC machining for high-volume production?

No doubt, CNC machining is scalable and works very well in both low-volume prototyping and high-volume production runs.

Q7. Why you consider premium parts for CNC machining Service?

Premium Parts offers CNC machining services using the latest technology for precision, quality, and cost-effectiveness. We have experienced workers who collaborate closely with our clients. They fulfill custom needs for producing high-quality manufactured products.