What’s Polishing? Essential Techniques for a Perfect Surface

Polishing goes beyond simple spraying and finishes; it’s an art that hides impurities. It enhances the appearance of the material and eliminates imperfections. Usually, after manufacturing, the end products come with some flaw...

Using Side Action for Injection Mold Design Optimization

If you’re using injection molding side action for design optimization, CNC advancements have made the process more precise. Through side actions, designers can create intricate designs that maintain functional improvement...

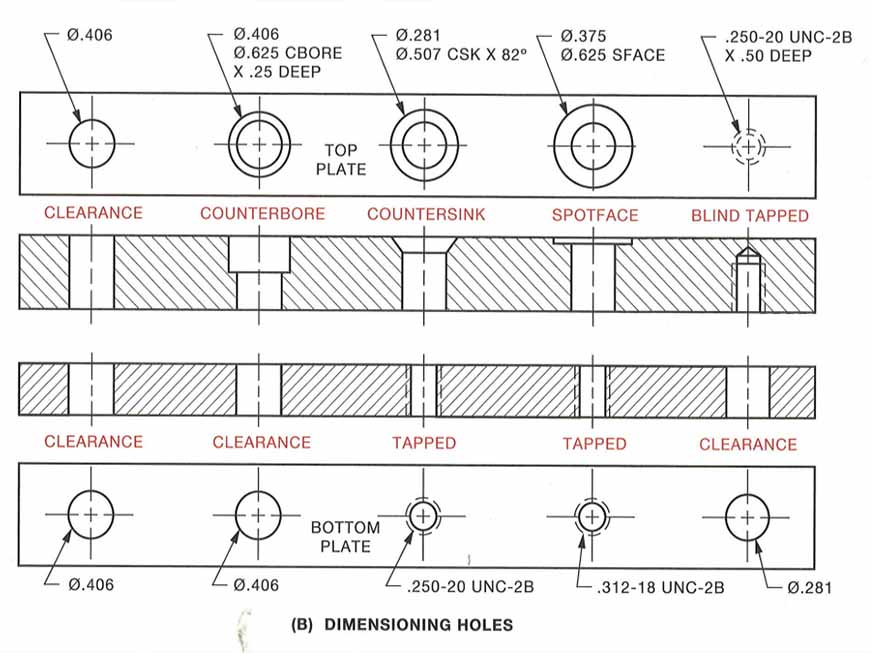

Different Types of Holes in Engineering – In-depth Guide

What are the holes in engineering and manufacturing? Generally, a hole is a pit or opening made by drilling or boring into a workpiece. These holes come in different sizes, shapes, and uses. Moreover, their depth and orientatio...

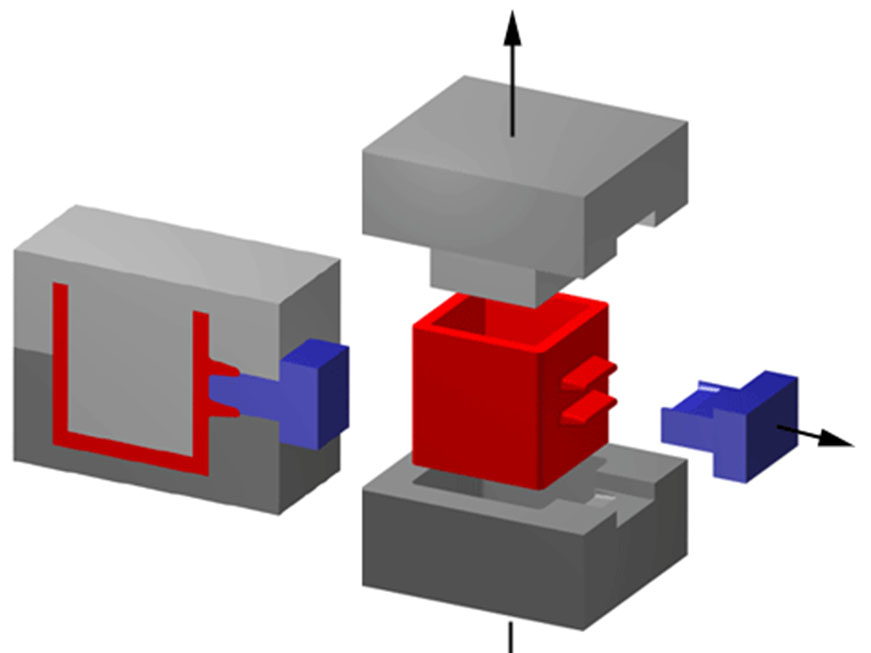

Metal Punching Vs. Stamping_ What Are The Differences

In sheet metal fabrication, metal stamping vs punching is often used. These techniques seem quite similar in their terminology and are often used interchangeably, but the processes are different based on their applications. The...

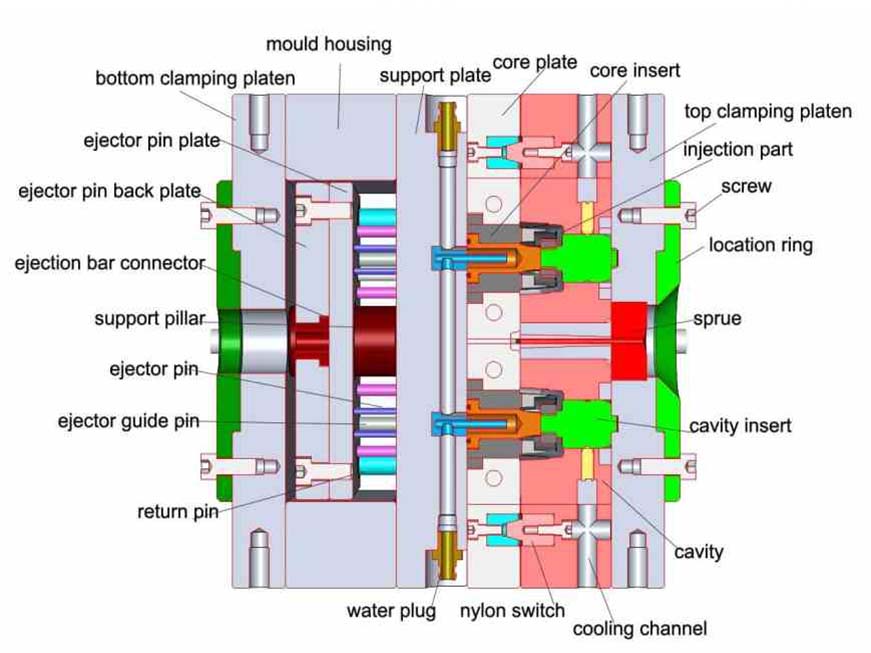

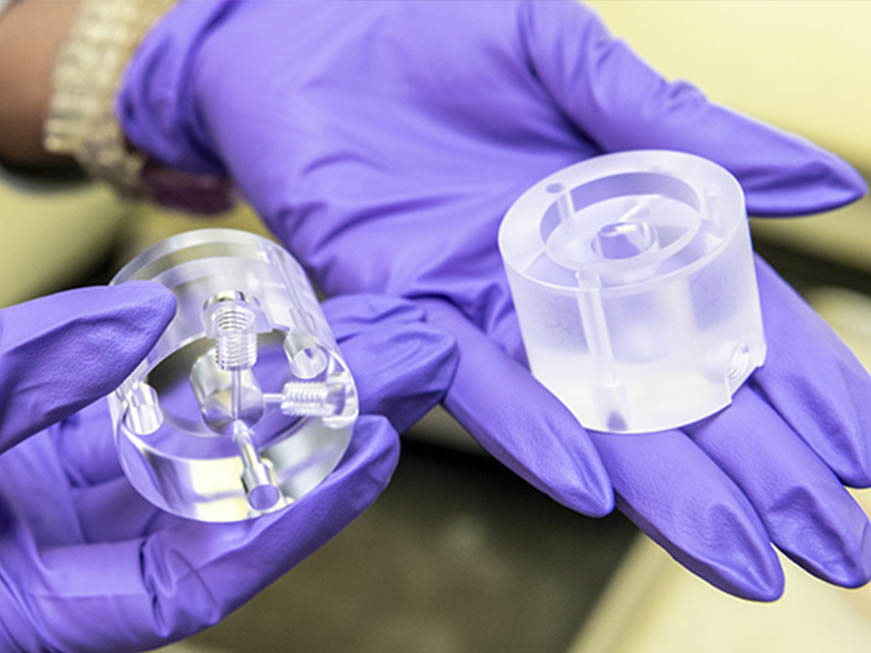

What Are The Common Injection Mold Components

Injection molding is an essential manufacturing process in the plastic fabrication industry. Whether you’re an engineer, manufacturer, or designer, you’ve probably relied on it for producing complex, precise parts/products. The...

Face Mill VS End Mill_ What Are The Key Differences

In the metal removal process, milling uses rotary cutters, which separate extra portions from the input material in an efficient way. Manufacturing companies rely heavily on milling operations to perform accurate material swaps...

Selecting the Best CNC Software for your CNC Machining

CNC software is the brain for any modern product manufacturing operation. As an engineer, machinist, or manufacturer, you must understand how important it is to select the best tool for your application. But with so many softwa...

A Guide To Welding Process, Types, & Considerations

Welding stands as a pivotal part of uniting techniques in contemporary manufacturing and construction works. Manufacturers need metal connections that maintain precision and long-lasting performance. It sustains its position si...

Vapor Polishing Finish for a Smooth, Glossy Surface – Comprehensive Guide

How come transparent and other plastic parts have smooth and flawless finishes with minimal imperfections? You don’t need to ponder this point much, as the answer is vapor polishing. Vapor polishing is a finish that helps creat...

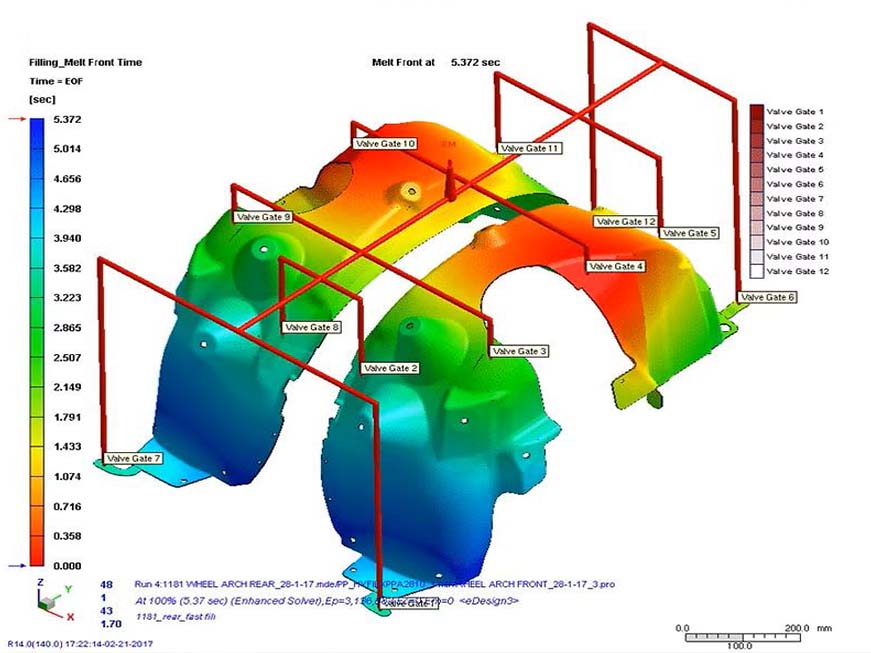

Mold Flow Analysis for Improving Product Design

The Mold Flow Analysis provides significant support for manufacturing products by simulating material flow in mold applications. You, as a machinist or engineer, can use a mold analysis approach to make your desired product. Th...